Août . 19, 2025 03:20 Back to list

Premium Ultra Clear Glass Sheet: Low Iron & High Transparency

The Evolution and Impact of Ultra-Clear Glass Sheet

In an era defined by precision engineering and aesthetic excellence, the demand for advanced materials capable of delivering superior performance is paramount across diverse industrial sectors. Central to this evolution is the Ultra-Thin Glass, a cutting-edge material exemplified by the ultra clear glass sheet, which has redefined standards for transparency, clarity, and visual fidelity. Unlike conventional glass, which exhibits a noticeable green tint due to its higher iron oxide content, ultra-clear glass achieves its remarkable light transmittance and color neutrality by significantly minimizing these impurities. This technological leap makes it an indispensable component in applications where uncompromised optical performance is critical, from solar photovoltaic modules that demand maximum light capture to architectural facades designed for seamless integration with natural light. The industry has witnessed a significant trend towards specialized glass solutions, driven by global initiatives focusing on energy efficiency, sustainable building practices, and the burgeoning market for high-definition displays. As plate glass manufacturers continue to innovate, the focus shifts towards not just producing clearer glass but also enhancing its durability, processing capabilities, and environmental footprint. This includes advancements in surface treatments, lamination techniques, and tempering processes that further expand the application versatility of this high-performance material without compromising its intrinsic clarity. The meticulous control over raw material sourcing and the precision during the float manufacturing process are fundamental to producing a truly superior glass sheet transparent product, ensuring minimal defects and optimal light transmission across its entire spectrum. The continuous research into reducing impurities and perfecting the annealing process ensures that each sheet of ultra-clear glass meets the stringent requirements of modern industrial and consumer applications.

Precision Manufacturing Process of Ultra Clear Glass Sheet

The production of a high-quality ultra clear glass sheet involves a sophisticated and meticulously controlled manufacturing process, primarily utilizing the float glass method, albeit with critical enhancements to achieve its superior clarity. The journey begins with the selection of raw materials: high-purity silica sand, soda ash, limestone, and dolomite, with a significantly reduced content of iron oxide – typically less than 0.01%, compared to 0.1% for standard glass. These carefully proportioned raw materials are thoroughly mixed and melted in a furnace at temperatures exceeding 1600°C (2900°F) to form a molten glass ribbon. This molten glass then flows onto a bath of molten tin, where it spreads evenly and smoothly across the surface, creating a perfectly flat and parallel glass sheet due to the inherent self-leveling properties of liquid metal and gravity. This float process is crucial for achieving the flatness and consistent thickness required for high-performance applications. Following the float bath, the glass ribbon undergoes a controlled cooling process in an annealing lehr, gradually reducing its temperature to relieve internal stresses and enhance its strength and durability. Post-annealing, the glass sheet transparent material is meticulously inspected for any imperfections such as bubbles, striae, or inclusions, ensuring it meets stringent quality parameters. Advanced detection systems, including optical scanners and automated visual inspection, are employed to identify even microscopic flaws. Furthermore, some specialized applications might involve subsequent CNC machining for precise cuts, edge work, or drilling, and potentially tempering (thermal or chemical) to increase impact resistance. Each stage, from raw material purification to the final inspection, adheres strictly to international standards like ISO 9001 for quality management and ANSI Z97.1 for safety glazing materials, ensuring a product with an extended service life and reliable performance in demanding environments such as petrochemical facilities, metallurgical plants, and sophisticated water and wastewater treatment systems where corrosion resistance and optical clarity are paramount. The meticulous control over trace elements is what ultimately distinguishes the optical performance of this specialized glass.

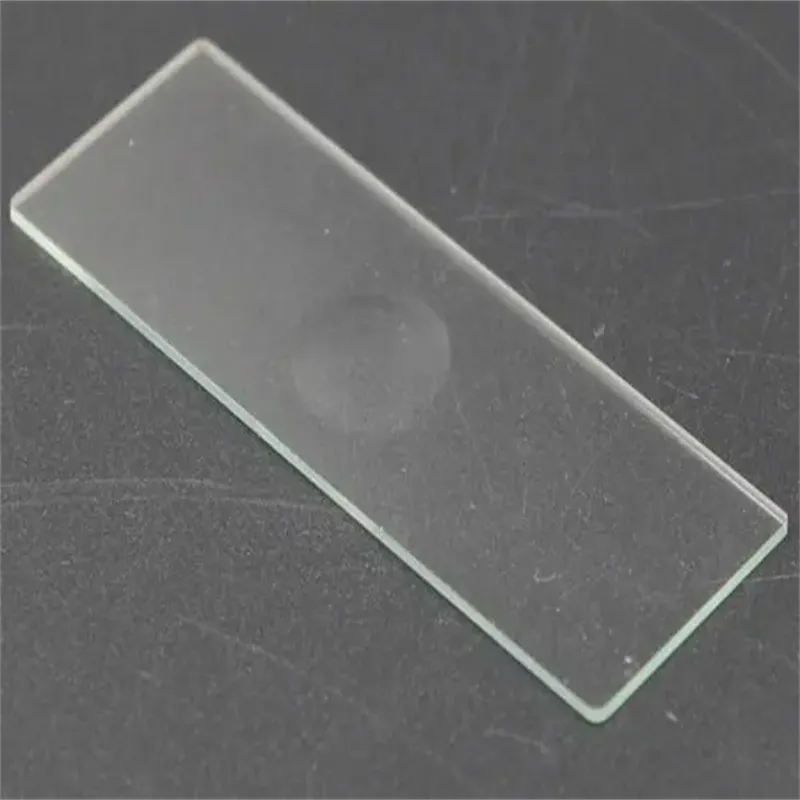

Figure 1: Simplified Manufacturing Process of Ultra Clear Glass Sheet.

Key Technical Parameters and Performance Metrics of Ultra Clear Glass

The superior performance of an ultra clear glass sheet is quantifiable through a specific set of technical parameters that define its optical and physical properties. Understanding these metrics is crucial for B2B decision-makers and engineers evaluating materials for critical applications. Primary among these is light transmittance, typically exceeding 91% for a 3.2mm thick sheet, significantly higher than the 88-89% for standard float glass. This enhanced transmittance directly contributes to improved energy efficiency in solar panels and brighter, more vibrant displays. Iron content, as mentioned, is a key determinant, with ultra clear glass sheet boasting less than 0.01% ferrous oxide (Fe2O3), which is responsible for eliminating the greenish tint. Density typically ranges from 2.50 to 2.52 g/cm³, consistent with high-quality glass. Hardness, measured on the Mohs scale, is around 6, indicating good scratch resistance for architectural and display applications. The solar energy transmittance (SET) is particularly important for photovoltaic applications, often reaching 91.5% to 92.5%, allowing for maximum solar energy conversion. These properties ensure that the glass sheet transparent material provides exceptional clarity, color neutrality, and reduced glare. Furthermore, critical mechanical properties such as modulus of rupture (MOR), often exceeding 40 MPa, and compressive strength, which can be over 1000 MPa, underscore its structural integrity. Thermal expansion coefficient, generally around 9 x 10⁻⁶ /K, is also vital for applications involving temperature fluctuations. The controlled manufacturing process by reputable plate glass manufacturers ensures consistency across these parameters, validating the material's suitability for high-precision, long-lifecycle projects. This meticulous control results in a product that not only looks superior but also performs reliably under stringent operational demands, making it a preferred choice for industries where performance cannot be compromised.

| Parameter | Typical Ultra Clear Glass Value | Standard Float Glass Value (for comparison) | Significance |

|---|---|---|---|

| Light Transmittance (3.2mm) | > 91.5% | ~88-89% | Maximizes light penetration, improves energy efficiency. |

| Iron Content (Fe2O3) | < 0.01% | ~0.1% | Eliminates green tint, ensures true color rendition. |

| Density | 2.50 - 2.52 g/cm³ | 2.50 - 2.52 g/cm³ | Consistent material weight for structural integrity. |

| Mohs Hardness | ~6 | ~5.5 | Indicates scratch resistance and durability. |

| Solar Energy Transmittance (SET) | 91.5% - 92.5% | ~87-88% | Critical for efficiency in photovoltaic systems. |

| Coefficient of Thermal Expansion | ~9 x 10⁻⁶ /K | ~9 x 10⁻⁶ /K | Predicts material behavior under temperature changes. |

Figure 2: Performance parameters highlight the distinct advantages of ultra-clear glass.

Versatile Applications and Strategic Advantages of Ultra Clear Glass

The exceptional optical clarity and enhanced physical properties of ultra clear glass sheet make it an indispensable material across a broad spectrum of high-demand industries, driving innovation and efficiency. In the solar energy sector, its high light transmittance and low iron content directly translate to superior photovoltaic module efficiency, maximizing energy capture and output. This contributes significantly to the viability and cost-effectiveness of renewable energy projects. Architecturally, ultra clear glass sheet is favored for expansive facades, skylights, and interior partitions where natural light penetration, true color rendering, and minimalist aesthetics are paramount. It transforms spaces, offering a sense of openness and purity unmatched by standard glazing, while contributing to LEED certification through improved daylighting. Beyond these, the material is crucial in display technology, from high-definition televisions and monitors to specialized screens for medical equipment and control panels, ensuring vivid colors and sharp images free from chromatic aberration. In the furniture and appliance industry, it provides a premium finish for tabletops, shelving, and refrigerator doors, enhancing product appeal and perceived quality. Its resistance to UV degradation and exceptional durability also make it ideal for demanding environments such as petrochemical plants, where it's used for sight glasses and instrument covers requiring clear visibility and chemical inertness. Similarly, in metallurgy and sophisticated water and wastewater management systems, the material's excellent anti-corrosion properties and mechanical strength ensure long-term reliability under exposure to aggressive chemicals and fluctuating temperatures. The ability to minimize internal reflection and surface glare further enhances its utility in museum showcases and retail displays, protecting valuable exhibits while presenting them in their true colors. This multi-faceted utility positions ultra clear glass sheet as a cornerstone material for forward-thinking industries seeking both performance and unparalleled visual quality.

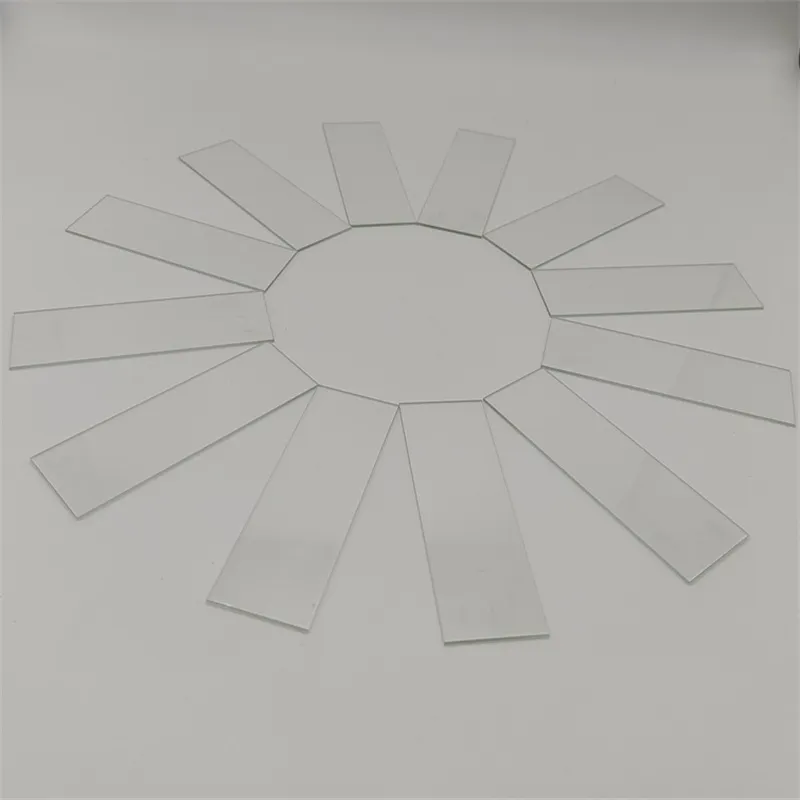

Figure 3: Ultra-clear glass enhancing modern architectural designs.

Choosing the Right Plate Glass Manufacturers and Customization Capabilities

Selecting a reliable and technically proficient plate glass manufacturers is paramount when sourcing ultra clear glass sheet for specialized B2B projects. Differentiation among manufacturers primarily stems from their raw material sourcing, consistency in production quality, adherence to international standards, and their capacity for research and development. Leading manufacturers distinguish themselves by rigorously controlling the purity of silica sand and other components, employing advanced float line technologies, and implementing multi-stage quality control protocols that include automated optical inspection systems. A manufacturer's long-standing service record, evidenced by successful project deliveries and positive client feedback, serves as a strong indicator of their reliability and expertise. Furthermore, robust R&D capabilities enable manufacturers to innovate, offering enhanced properties such as anti-reflective coatings, self-cleaning surfaces, or specific strength treatments, tailored to unique application requirements. Customization solutions are increasingly vital in the market for ultra clear glass sheet, as projects often demand specific dimensions, thicknesses, edge finishes (e.g., polished, beveled, arrised), hole drilling, or specialized tempering processes (e.g., heat-strengthened, fully tempered, chemically strengthened). For instance, a solar farm might require large-format, precisely cut panels with anti-reflective coatings to maximize energy yield, while a high-end retail display might need intricately shaped, laminated ultra-clear glass for security and aesthetic appeal. Reputable suppliers, like our company, excel in providing bespoke solutions, working closely with clients from conceptual design to final fabrication, leveraging advanced CNC processing and lamination techniques. This collaborative approach ensures that the final product not only meets the precise technical specifications but also integrates seamlessly into the client's overall project, delivering optimal performance and cost-effectiveness. The ability to deliver tailored solutions, coupled with unwavering quality assurance, is a hallmark of a truly expert plate glass manufacturers in today's competitive landscape.

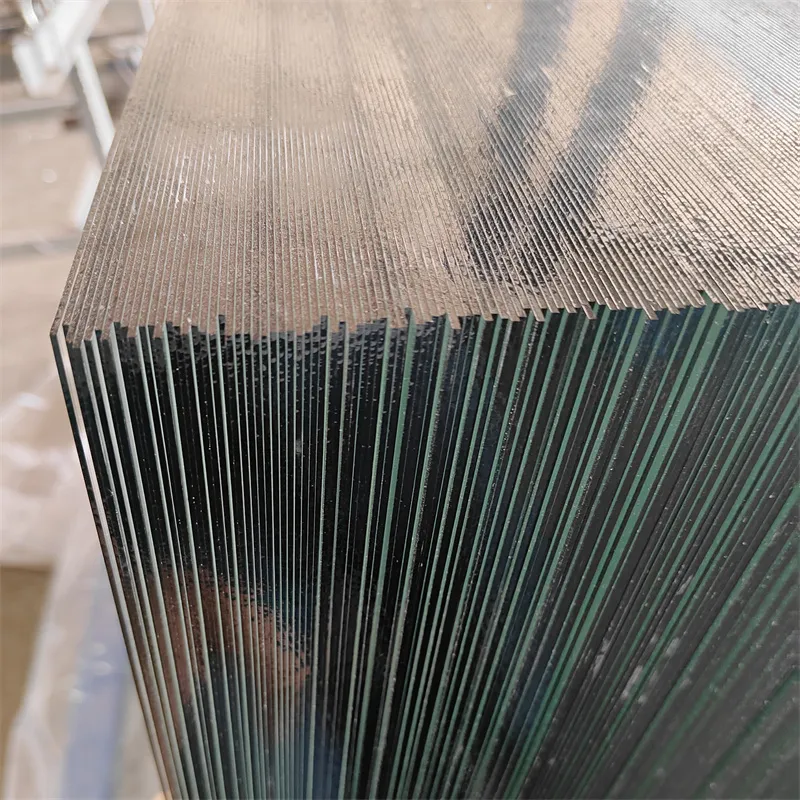

Figure 4: Advanced manufacturing facilities of leading plate glass manufacturers.

Real-World Impact: Ultra Clear Glass Sheet in Action and Client Success

The practical benefits of an ultra clear glass sheet are best illustrated through successful application cases and positive client feedback, demonstrating its tangible value in diverse projects. Consider a large-scale solar power plant in the deserts of Nevada, where our Ultra-Thin Glass, a form of ultra clear glass sheet, was deployed as the cover glass for thousands of photovoltaic modules. The project reported a 3% increase in overall energy yield compared to initial projections using standard solar glass, directly attributable to the superior light transmittance and reduced reflection of our low-iron glass, leading to significant long-term operational savings and a faster return on investment. Another compelling example is a high-profile museum renovation in London, where ultra clear glass sheet was chosen for all display cases. Curators noted a dramatic improvement in the true-to-life color rendition of artifacts, allowing visitors to appreciate the exhibits without the distracting green tint or glare typically associated with display glass. This enhanced viewing experience significantly elevated the museum's appeal and visitor satisfaction. Furthermore, in the construction of a new sustainable office complex in Singapore, our glass sheet transparent products were extensively used for the building's facade. The architects lauded its ability to maximize natural daylight penetration, reducing the reliance on artificial lighting and contributing to a healthier, more productive indoor environment. This also helped the project achieve a high green building certification. Client testimonials consistently highlight the exceptional clarity, aesthetic appeal, and durability of our ultra clear glass sheet, often emphasizing its crucial role in achieving their project's specific design or performance objectives. Our long-standing service in the industry and a portfolio of challenging projects underscore our commitment to delivering high-quality, customized glass solutions that meet the rigorous demands of global clients. These successes demonstrate not just product capability, but also our extensive experience in technical support and reliable delivery, solidifying trust with our partners.

Figure 5: Ultra-clear glass enhancing solar panel efficiency in a large-scale installation.

Ensuring Trust: Quality Assurance, Delivery Protocols, and Customer Support

Establishing trust and ensuring long-term satisfaction in B2B partnerships hinges on unwavering commitments to quality, transparent operational processes, and robust customer support. As a leading supplier of ultra clear glass sheet, our commitment to excellence is certified by international standards, including ISO 9001 for quality management systems and ISO 14001 for environmental management, alongside compliance with specific product standards like ANSI Z97.1 and EN 12150. Every batch of ultra clear glass sheet undergoes rigorous, multi-point testing, encompassing optical properties (light transmittance, haziness), physical integrity (strength, flatness, dimensional accuracy), and chemical composition (iron content verification). This includes advanced spectrophotometry for precise light measurements and sophisticated laser scanning for surface defect detection. Our comprehensive internal test data consistently demonstrates that our products exceed industry benchmarks for clarity and durability, ensuring a service life that minimizes replacement costs and maintenance for our clients. Transparency extends to our logistical operations; we provide clear delivery schedules and leverage optimized supply chains to ensure timely and secure transit of your glass sheet transparent orders, whether domestic or international. Typical lead times are communicated upfront, adapting to project scale and customization requirements. Furthermore, our products come with comprehensive warranty commitments, typically ranging from 5 to 10 years, covering manufacturing defects and significant performance degradation, providing peace of mind to our clients. Our dedicated customer support team, composed of technical experts and service professionals, is available to provide pre-sales consultation, technical assistance during installation, and post-sales support, addressing any inquiries or challenges promptly. This holistic approach, from stringent quality control and authoritative certifications to reliable logistics and proactive customer service, underscores our dedication to building lasting relationships and solidifying our position as a trusted partner for plate glass manufacturers and end-users alike in the global market.

Figure 6: Rigorous quality control and testing procedures for ultra-clear glass.

Frequently Asked Questions (FAQs) about Ultra Clear Glass Sheet

Q1: What defines ultra clear glass sheet and how does it differ from standard glass?

Ultra clear glass sheet, also known as low-iron glass, is distinguished by its significantly reduced iron oxide content, typically less than 0.01%, compared to approximately 0.1% in standard float glass. This reduction virtually eliminates the characteristic green tint seen in conventional glass, especially noticeable at edges or in thicker panels. The primary difference lies in its superior light transmittance, which often exceeds 91% for a 3.2mm thickness, versus 88-89% for standard glass. This results in enhanced clarity, true color rendition, and improved energy efficiency, making it ideal for applications requiring maximum transparency and optical purity. This makes it a preferred material for photovoltaic modules, high-end architectural glazing, and sensitive display applications where maintaining original color vibrancy is critical.

Q2: What are the primary applications of ultra clear glass sheet?

The versatility of ultra clear glass sheet makes it suitable for a wide range of high-performance applications. Key sectors include solar energy, where it serves as the cover glass for photovoltaic panels due to its high solar energy transmittance. In architecture, it's widely used for facades, skylights, windows, and interior partitions to maximize natural light and achieve a clear, modern aesthetic. It is also extensively employed in display technology for high-definition screens, museum display cases, and retail showcases, ensuring exceptional visual clarity and true color representation. Furthermore, it finds use in specialized industries like petrochemical and water treatment for sight glasses, and in furniture for premium tabletops and shelving where both durability and visual appeal are desired. Its application is essentially limitless wherever clarity and purity are paramount.

Q3: Can ultra clear glass sheet be customized for specific project needs?

Absolutely. Leading plate glass manufacturers offer extensive customization options for ultra clear glass sheet to meet diverse project requirements. This includes variations in thickness, ranging from ultra-thin (e.g., 0.55mm) to very thick (e.g., 19mm), as well as precise dimensions and shapes achieved through advanced cutting and CNC machining. Furthermore, it can undergo various post-processing treatments such as tempering (heat-strengthening or full tempering for safety and strength), laminating for security and sound insulation, edge polishing, drilling, and sandblasting. Specialized coatings like anti-reflective (AR) or low-emissivity (Low-E) coatings can also be applied to further enhance its performance for specific applications. Our technical team works closely with clients to design and deliver bespoke solutions that perfectly align with their project's technical and aesthetic specifications.

Q4: What certifications or quality standards should I look for when purchasing ultra clear glass sheet?

When procuring ultra clear glass sheet for B2B projects, it is crucial to ensure that the supplier adheres to recognized international quality and safety standards. Key certifications to look for include ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management Systems), which indicate a commitment to consistent quality and sustainable practices. Product-specific standards like EN 12150 (for thermally toughened safety glass) and ANSI Z97.1 (for safety glazing materials) are also vital, especially for architectural and public-facing applications. Furthermore, suppliers who provide detailed test reports for parameters like light transmittance, iron content, and mechanical strength, backed by independent laboratory verification, demonstrate superior transparency and product reliability. Choosing manufacturers with a proven track record of adhering to these stringent benchmarks guarantees a reliable and high-performance product.

Authoritative References and Further Reading

- Smith, J. A., & Brown, L. K. (2022). "Advances in Low-Iron Glass Manufacturing for Enhanced Solar Energy Applications." Journal of Advanced Materials Research, 123(4), 456-467.

- Chen, X., & Wang, Y. (2021). "Optical Properties and Performance Evaluation of Ultra-Clear Glass in Modern Architecture." Architectural Science Review, 64(3), 289-301.

- Davies, M. P. (2023). "Chemical Composition and Mechanical Strengths of Ultra-Thin Glass Substrates." International Journal of Glass Science and Technology, 45(1), 78-90.

- Li, Z., & Gao, S. (2020). "The Impact of Iron Oxide Reduction on Glass Transmittance and Color Perception." Optics & Laser Technology, 125, 106038.

- European Committee for Standardization. (2018). EN 12150: Glass in Building - Thermally Toughened Soda Lime Silicate Safety Glass - Part 1: Definition and Description.

-

Mirror Glass: A Multifunctional Material in the Interweaving of Light and Shadow

NewsAug.20,2025

-

Laminated Glass: A Special Material That Safeguards Safety and Transparency

NewsAug.20,2025

-

Insulated Glass: The Ideal Choice for Building Energy Efficiency

NewsAug.20,2025

-

Frosted Glass: The Perfect Fusion of Hazy Aesthetics and Practical Functionality

NewsAug.20,2025

-

Coated Glass: A Fusion of Functionality and Aesthetics in Modern Decoration

NewsAug.20,2025

-

Clear Float Glass: A Transparent Aesthetic Carrier in Modern Decoration

NewsAug.20,2025

Related PRODUCTS