Verre renforcé chimiquement

Descriptions du verre renforcé chimiquement

Chemically strengthened glass, also known as chemically toughened glass, is a special type of glass that is immersed in molten potassium salts to cause an ion replacement reaction on the glass surface to enhance its strength and scratch resistance. Compared with ordinary annealed glass, chemically strengthened glass shows better impact resistance and temperature difference adaptability, which makes it widely used in construction, automobiles, aerospace, and other fields.

Comment produire du verre renforcé chimiquement ?

Le renforcement chimique du verre est un processus simple et intéressant. Il modifie principalement les caractéristiques du verre ordinaire par échange d'ions sur la surface du verre, ce qui permet de renforcer le verre. Voici son principal processus de production :

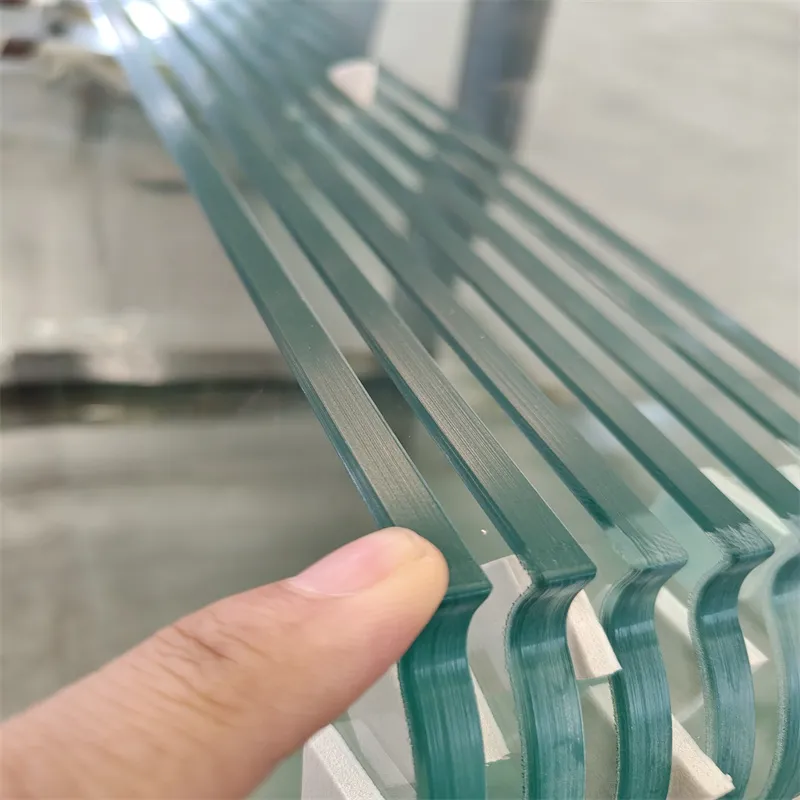

Avant le traitement chimique, le verre nettoyé doit être coupé à la taille souhaitée.

Soak the cut glass in a potassium nitrate salt bath at about 400 ℃ to wait for ion exchange to occur.

Les ions sodium présents à la surface du verre sont remplacés par des ions potassium dans le bain de sel. Ce processus prend généralement 6 heures ou plus. Le verre est ensuite retiré et refroidi à température ambiante pour terminer l'ensemble du processus de renforcement chimique.

Caractéristiques du verre renforcé chimiquement

Chemically strengthened glass is 3 to 8 times stronger than ordinary float glass, allowing it to withstand greater impact.

Chemically strengthened glass has good thermal stability and can withstand temperature changes above 150°C.

À mesure que la résistance du verre augmente, la résistance aux rayures du verre renforcé chimiquement a également été considérablement améliorée par rapport au verre non traité.

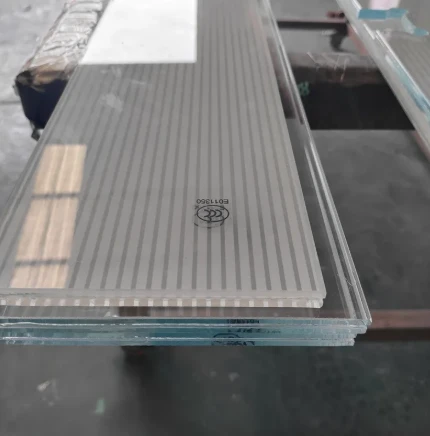

Comparé à thermiquement verre trempéLe verre renforcé chimiquement présente d’excellents avantages pour maintenir la planéité de la surface du verre.

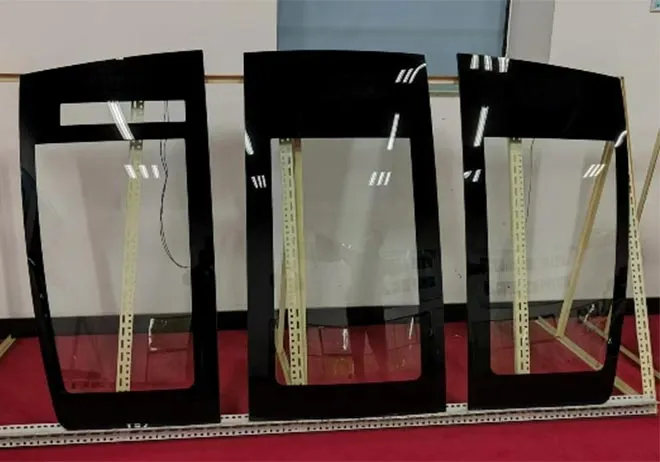

Comme nous le savons tous, la trempe thermique ne convient que pour tremper le verre plat, tandis que le renforcement chimique peut traiter du verre de formes diverses. Cela lui confère un rôle irremplaçable dans de nombreux domaines.

Étant donné que le renforcement chimique nécessite un temps de réaction chimique long, son coût est beaucoup plus élevé que celui de la trempe thermique.

When chemically strengthened glass is damaged, it will break into large, sharp pieces, which will increase the chance of human injury, so regular chemically strengthened glass is not safety glass.

Applications spécifiques du verre renforcé chimiquement

We ShottGlass, have focused on manufacturing chemically strengthened glass for many years and have accumulated rich production experience. With a professional team and rigorous work attitude, we can provide clients with the best solutions for chemically strengthened glass. The following are our specific product applications:

Bouclier anti-explosion

Verre anti-effraction

Fenêtres d'avion

Vitres d'automobile

Fenêtres du train à grande vitesse

Façades de bâtiments

Vitrine à bijoux en verre

Autres applications nécessitant du verre renforcé chimiquement.

Advantages of Chemically Strengthened Glass with Shottglass

When it comes to high-performance glass solutions, chemically strengthened glass stands at the forefront of innovation, and Shottglass is proud to lead the way. Engineered through an advanced ion-exchange process, chemically strengthened glass offers exceptional strength, durability, and versatility, making it an ideal choice for a wide range of applications, from mobile devices and automotive displays to architectural panels and home appliances.

One of the most notable advantages of chemically strengthened glass is its superior impact resistance. Unlike regular annealed glass, this special glass type undergoes a chemical tempering process that exchanges smaller sodium ions with larger potassium ions on the surface. This creates a layer of compressive stress that significantly improves the glass’s ability to withstand mechanical shocks and drops, often up to five times stronger than standard glass. At Shottglass, we’ve refined this process to deliver consistent, high-quality results that meet stringent industry standards.

Another key benefit is its optical clarity and aesthetic flexibility. Chemically strengthened glass maintains an ultra-smooth surface and high transparency, even after tempering. This makes it perfect for products where visual quality matters, such as smartphones, touchscreen kiosks, and interactive displays. With Shottglass, clients can expect crystal-clear glass that enhances user experience while retaining structural integrity.

In addition, Shottglass chemically strengthened glass is resistant to scratches, bending, and thermal stress. Its enhanced durability translates to longer product lifespans and reduced maintenance costs, which is particularly valuable in demanding commercial or industrial environments. Whether you're designing for transportation, consumer electronics, or architectural glazing, Shottglass ensures your product not only looks sleek but also performs under pressure.

Finally, the versatility of our chemically strengthened glass extends to customization. Shottglass offers tailored solutions including curved shaping, ultra-thin formats, and anti-reflective coatings to meet your specific design and functionality needs. We work closely with OEMs and designers to deliver precision-engineered glass that elevates both performance and appearance.

At Shottglass, we don’t just make glass—we redefine what it can do. Choose chemically strengthened glass from Shottglass for a stronger, smarter, and sleeker solution to your toughest design challenges.

Classification of Chemically Strengthened Glass

Chemically strengthened glass has become a preferred material across a wide range of industries, from smartphones to architecture, thanks to its superior strength, scratch resistance, and optical clarity. Unlike tempered glass, which is strengthened by heat, chemically strengthened glass undergoes an ion-exchange process that compresses its surface layers, greatly increasing durability without compromising thickness or transparency. Based on composition, application, and strength requirements, chemically strengthened glass can be classified into several types.

1. Aluminosilicate Glass

One of the most commonly used types, aluminosilicate glass, is primarily made of aluminum oxide and silicon dioxide. It is widely used in mobile devices, tablets, and other consumer electronics. This type of glass is valued for its exceptional resistance to thermal shock and impact. Popular commercial variants like Gorilla Glass fall into this category, offering high strength and scratch resistance in ultra-thin formats.

2. Sodium-Cation Glass

This is the standard type used in many general applications. The strengthening process involves replacing smaller sodium ions in the glass surface with larger potassium ions. This ion exchange creates a layer of compressive stress, enhancing resistance to mechanical damage. It is often used in touch panels, glass display covers, and some architectural elements.

3. Lithium Aluminosilicate Glass

Used in high-performance applications, this glass offers a unique combination of low thermal expansion and high mechanical strength. Its chemical durability and resistance to thermal shock make it suitable for aerospace, high-end cookware, and laboratory glassware. It is also gaining popularity in precision optics due to its dimensional stability.

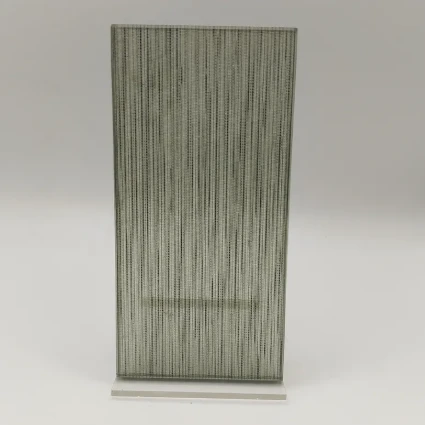

4. Hybrid Glass Types

In recent years, hybrid chemically strengthened glasses have emerged by combining various oxide systems to achieve specific performance goals—such as enhanced flexibility, reduced brittleness, or improved resistance to etching and wear. These are often custom-engineered for advanced electronics, folding displays, or even biomedical devices.

Each type of chemically strengthened glass serves a different purpose, and the right choice depends on the intended application, desired strength, and environmental exposure. As technology continues to advance, the classification and innovation of chemically strengthened glass will keep evolving, meeting new demands in both performance and design.

Chemically Tempered Glass FAQs

What is chemically tempered glass?

Chemically tempered glass, also known as chemically strengthened glass, is a type of glass that has been reinforced through an ion-exchange process. Unlike heat-tempered glass, this process involves submerging the glass in a bath of molten potassium salt, where smaller sodium ions in the glass are replaced by larger potassium ions. This creates a layer of surface compression, making the glass significantly stronger without changing its appearance or thickness.

How is chemically tempered glass different from heat-tempered glass?

The main difference lies in the strengthening method. Chemically tempered glass is strengthened at the molecular level using ion exchange, resulting in higher surface compression and more precise thickness tolerances. Heat-tempered glass, on the other hand, is thermally treated and may be thicker and less optically clear. Chemically tempered glass also tends to have better scratch resistance and is often used where ultra-thin or optically pure glass is required.

Where is chemically tempered glass commonly used?

Chemically tempered glass is widely used in smartphones, tablets, touch panels, automotive displays, high-end optics, and certain architectural or aerospace components. It’s favored for its combination of strength, scratch resistance, and clarity, especially in thin formats.

Is chemically tempered glass safe when broken?

Unlike heat-tempered glass, which breaks into small, blunt fragments, chemically tempered glass breaks more like regular annealed glass—into sharp shards. This means it offers excellent strength and impact resistance but may not be ideal for applications where safety glass behavior (safe shattering) is required.

Can chemically tempered glass be cut or drilled after tempering?

No. Once glass has been chemically strengthened, cutting, drilling, or grinding it can cause it to crack or shatter due to the built-up surface stress. All machining should be completed before the tempering process.

Is chemically tempered glass more expensive?

Generally, yes. The chemical tempering process is more time-consuming and requires specialized equipment and materials, such as molten salt baths. However, for high-performance applications, the added durability and thinness often justify the cost.

-

24Jun

24JunSafety and Style with Premium Laminated Glass Solutions

ShottGlass continues to set the industry benchmark with its high-quality laminated glass offerings, serving customers worldwide who demand superior performance, elegant design, and unmatched safety.

apprendre encore plus -

24Jun

24JunReinvents Security with Premium Wired Glass

In today’s high-security environments, safety and transparency must go hand in hand.

apprendre encore plus -

24Jun

24JunPremium Float Glass Line for Modern Architecture

As construction and design industries continue to evolve, so does the demand for clarity, strength, and innovation in building materials.

apprendre encore plus