Août . 07, 2025 14:08 Retour à la liste

Insulated Glass Unit Installation Best Practices and Tips

In the competitive market of glass products, understanding the ins and outs of unité de vitrage isolant is crucial for wholesalers. From the materials and types available for sale to the best installation practices, each aspect plays a significant role in meeting customer needs and ensuring the success of projects.

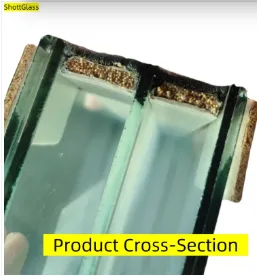

Components and Types of Insulated Glass Units for Sale

Main Materials of Insulated Glass Units: The main materials needed to make an unité de vitrage isolant are two or more pieces of high-quality flat glass, aluminum alloy frame, spacer bar, desiccant, sealant, etc. The following table details the essential components and their functions:

|

Component |

Function |

|

High-quality flat glass |

Forms the main structure, and different types of glass can achieve various insulation and aesthetic effects |

|

Aluminum alloy frame |

Provides structural support and a framework for assembling the glass and other components |

|

Spacer bar |

Creates a space between the glass sheets, which is filled with air or other gases for insulation |

|

Desiccant |

Absorbs moisture within the unit to prevent fogging and maintain clarity |

|

Sealant |

Seals the unit to ensure airtightness and prevent gas leakage and moisture ingress |

Varieties of insulated glass units for sale :

Depending on the number of glass sheets, there are different types of unités de vitrage isolant à vendre, each with its own insulation characteristics.

|

Type of Insulated Glass Unit |

Description |

|

Double glazing |

Composed of two pieces of flat glass sealed in an aluminum frame with a special composite adhesive, creating a sealed dry space (air layer) between the glass for sound and heat insulation |

|

Triple glazing |

Utilizes three pieces of flat glass and two sets of spacers, separating the glass into two spaces (air layers), offering better insulation than double glazing |

|

Quadruple glazing |

Made with four pieces of flat glass, creating three spaces (air layers) between them, typically used in places with strict insulation requirements |

Glass Types for insulated glass units for sale :There are multiple types of glass that can be used in unités de vitrage isolant à vendre, resulting in different insulation effects. The mainstream types are as follows:

|

Type de vitrage isolant |

Glass Used |

Caractéristiques |

|

Float insulated glass |

Verre flotté transparent |

Forms ordinary-grade insulated glass |

|

Reflective insulated glass |

Verre réfléchissant |

Has a stronger insulation effect than single-piece reflective glass |

|

Low Emissivity insulated glass |

Low-E glass |

Offers a better insulation effect than single-piece Low-E glass |

|

Tempered insulated glass |

Tempered glass |

Greatly improves impact resistance, widely used in energy-saving buildings as safety insulated glass |

|

Laminated insulated glass |

Verre feuilleté |

Achieves excellent sound and heat insulation, also a type of safety insulated glass |

Specifications of Insulated Glass Units for Sale

Generally, an IGU for sale is composed of several pieces of glass of the same thickness. However, if there is a special purpose, an IGU for sale can also be made with glass of different thicknesses. The following are some common specifications:

|

Specification |

Détails |

|

Taille du verre |

600mm900mm,800mm1100mm,900mm1300mm, 1016mm1220mm, 1000mm1500mm,1500mm2000mm, etc. |

|

Épaisseur du verre |

4 mm, 5 mm, 6 mm, 8 mm, etc. |

|

Air layer thickness |

9mm - 15mm |

|

Épaisseur du cadre |

6mm - 12mm |

|

Laminated insulated glass dimensions |

(5+0.38pvb+5)+9A+6, (6+0.76pvb+6)+12A+(5+0.76pvb+5), (8+1.52pvb+8)+12A+(6+1.52pvb+6), etc. (Units: mm, A refers to Air Layer) |

Verre Shott:Your Source for Insulated Glass Units for Sale

We focus on offering one-stop solutions on glass processing for global OEM/ODM customers. To ensure precision processing of unités de vitrage isolant à vendre.We meet all-round needs of customers .

Insulated Glass Unit for Sale FAQS

What Factors to Consider When Buying Insulated Glass Units for Sale?

When purchasing unités de vitrage isolant à vendre, several factors require careful consideration. First and foremost, the intended application is crucial. For buildings in regions with extreme climates, triple or quadruple glazing might be the better option due to their enhanced heat insulation capabilities. The type of glass used in the unit also significantly impacts its performance. If noise reduction is a priority, laminated insulated glass should be at the top of the list. Moreover, accurate measurement of the installation site is essential to ensure that the size and thickness specifications of the IGU align perfectly.

How Do Different Glass Types Impact Insulated Glass for Sale?

The performance of insulated glass for sale is greatly influenced by the type of glass incorporated. Clear float glass, used in float insulated glass, offers basic insulation and transparency, suitable for standard applications. Reflective glass in reflective insulated glass is designed to reduce solar heat gain, making it an ideal choice for buildings in sunny areas. Low-E glass, utilized in Low Emissivity insulated glass, features a specialized coating that reflects infrared radiation, thereby significantly enhancing heat insulation. Tempered glass in tempered insulated glass provides increased strength and safety, making it a popular option for energy-saving buildings where safety is a concern. Laminated glass in laminated insulated glass, on the other hand, excels in noise insulation and offers additional safety features, as it remains intact even when broken, providing enhanced protection.

What Are the Fundamental Steps in Insulated Glass Unit Installation?

The installation of an unité de vitrage isolant involves a series of fundamental steps. Commence by thoroughly preparing the installation site, ensuring it is clean, dry, and free of any debris or obstructions that could interfere with the installation process. Next, take precise measurements and, if necessary, cut the frame to ensure a perfect fit for the IGU. then,apply an appropriate sealant around the frame to create an airtight barrier. Carefully position the insulated glass unit into the frame, making sure it is centered and level. Finally, use additional sealant or fasteners to firmly secure the IGU in place and conduct a thorough inspection to identify and address any potential air leaks or gaps. Professional installation services, backed by the expertise of companies like ShottGlass, can ensure that the IGU functions optimally and enjoys a long lifespan.

How Can the Longevity of Insulated Glass Units for Sale Be Prolonged?

Prolonging the lifespan of unités de vitrage isolant à vendre hinges on several key aspects. First and foremost, proper installation is non-negotiable. A meticulously installed IGU with a tight seal effectively prevents moisture and gas leakage, which are common culprits behind fogging and reduced insulation performance over time. Regular maintenance is equally crucial. Clean the glass regularly using non-abrasive cleaners to avoid scratching the surface, which can compromise its integrity. Periodically inspect the seals for any signs of wear, damage, or deterioration, and promptly replace them when necessary. Additionally, choosing high-quality insulated glass units from reputable suppliers, such as ShottGlass, can make a significant difference.

What Causes the Price Variation Among Insulated Glass Units for Sale?

The price variation among unités de vitrage isolant à vendre can be attributed to multiple factors. Units with a greater number of glass layers, such as triple or quadruple glazing, generally come with a higher price tag due to the increased consumption of materials and the more complex manufacturing processes involved. The type of glass used also has a substantial impact on the cost. Specialized glasses like Low-E glass or laminated glass, which offer enhanced performance features, are typically more expensive than regular clear float glass. Custom-sized IGUs often command a premium compared to standard sizes, as they require additional time, effort, and resources for production. However, while price is an important consideration for wholesalers, it should not overshadow the importance of performance and quality.

-

Sustainable Practices in a Modern Coated Glass Factory

NouvellesAug.07,2025

-

Frosted Glass Types and Custom Solutions for Sale

NouvellesAug.07,2025

-

Current Clear Float Glass Price Trends in Global Markets

NouvellesAug.07,2025

-

Comparing Different Types of Laminated Glass Performance

NouvellesAug.07,2025

-

Best Anti Fog Bathroom Mirror Solutions for Humid Climates

NouvellesAug.07,2025

En rapport PRODUITS