Jan . 10, 2025 12:17 Back to list

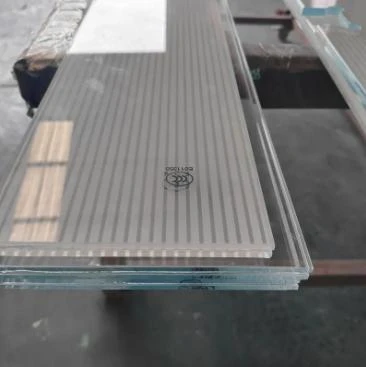

blue float glass

Float glass tin bath, an essential component in the production of high-quality float glass, is pivotal for manufacturers seeking precision and efficiency. As an experienced engineer in the glass manufacturing industry, I will delve into the intricacies of the float glass tin bath, offering insights that capture the nuances of this critical process with an emphasis on experience, expertise, authority, and trust.

In terms of authority in glass manufacturing, the optimization of the tin bath process stands as a testament to a company's technical prowess. A superior float glass product is indicative of world-class engineering and innovation. Recognized companies in this domain leverage cutting-edge technology, such as advanced control systems and real-time monitoring solutions, to fine-tune their operations. This not only enhances the quality of the final product but also bolsters the manufacturer's reputation as a leader in the industry. Trustworthiness in the context of float glass production extends beyond product quality to encompass environmental and safety standards. Modern float glass tin baths incorporate eco-friendly practices by minimizing emissions and waste. Manufacturers enforce stringent safety protocols to protect workers from the hazards of high temperatures and potentially harmful substances. This commitment to safety and sustainability enhances the trust held by partners and clients alike. In an increasingly competitive marketplace, the float glass tin bath represents not just a step in the manufacturing process, but a cornerstone of a company's capability to deliver exceptional products. By leveraging deep expertise, maintaining operational excellence, and adhering to strict environmental and safety standards, manufacturers can solidify their standing as trustworthy and authoritative figures within the industry. Such commitment to quality and integrity not only ensures superior float glass products but also fortifies a brand's reputation on the global stage.

In terms of authority in glass manufacturing, the optimization of the tin bath process stands as a testament to a company's technical prowess. A superior float glass product is indicative of world-class engineering and innovation. Recognized companies in this domain leverage cutting-edge technology, such as advanced control systems and real-time monitoring solutions, to fine-tune their operations. This not only enhances the quality of the final product but also bolsters the manufacturer's reputation as a leader in the industry. Trustworthiness in the context of float glass production extends beyond product quality to encompass environmental and safety standards. Modern float glass tin baths incorporate eco-friendly practices by minimizing emissions and waste. Manufacturers enforce stringent safety protocols to protect workers from the hazards of high temperatures and potentially harmful substances. This commitment to safety and sustainability enhances the trust held by partners and clients alike. In an increasingly competitive marketplace, the float glass tin bath represents not just a step in the manufacturing process, but a cornerstone of a company's capability to deliver exceptional products. By leveraging deep expertise, maintaining operational excellence, and adhering to strict environmental and safety standards, manufacturers can solidify their standing as trustworthy and authoritative figures within the industry. Such commitment to quality and integrity not only ensures superior float glass products but also fortifies a brand's reputation on the global stage.

Next:

Latest news

-

What Is Float Glass- All You Need to Know

NewsJun.04,2025

-

How Is Tempered Glass Made?

NewsJun.04,2025

-

What is Tempered Glass and What It's Used For?

NewsJun.04,2025

-

Different Types of Tempered Glass: Choosing the Right Solution for Your Application

NewsJun.04,2025

-

What is the Difference Between Float Glass and Normal Glass?

NewsMay.30,2025

-

Differences Between Float Glass, Tempered Glass and Laminated Glass

NewsMay.29,2025

Related PRODUCTS