Jan . 10, 2025 10:07 Back to list

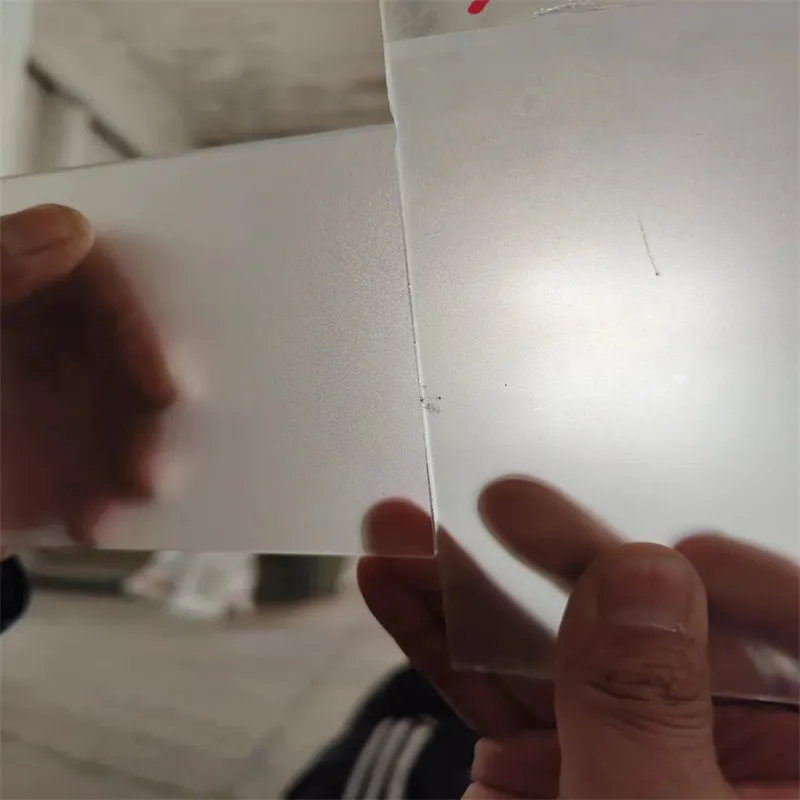

Float Glass

Float glass sheets, a technological marvel in the world of materials, have revolutionized industries with their unparalleled quality and versatility. Born from the ingenious float glass process, developed in the mid-20th century, these sheets offer a plethora of applications ranging from architectural masterpieces to automotive excellence.

The expert perception of float glass sheets extends to their environmental benefits. Thanks to the sustainable nature of glass, these sheets can be recycled without degradation of properties, reducing the carbon footprint of industries reliant on glass products. Recycled float glass can seamlessly find new life in construction projects or even in the manufacture of new float glass, closing the loop of sustainability. Industry experts who have witnessed the evolution of float glass sheets underscore their role as a transformative force. Their extensive research and development efforts continue to innovate in areas such as coatings that enhance energy efficiency and surfaces that combat the transmission of harmful UV rays. These advancements not only enhance the functionality of glass but also reinforce its role in promoting global energy-saving goals. Trust in float glass sheets is ingrained in their long-standing reputation for reliability and performance. Long-time users of float glass vouch for its unwavering quality, which has famously stood unyielding against the elements, providing peace of mind for residential and commercial users alike. Such trust is backed by certifications and rigorous testing standards adhered to by manufacturers worldwide. End-users, from construction firms to automakers, rely on float glass for its adaptability and proven track record. With cutting-edge techniques and adherence to international safety and quality standards, float glass sheets continue to define what is possible in modern applications, sustaining their place as an invaluable material in industries relying on transparency and strength.

The expert perception of float glass sheets extends to their environmental benefits. Thanks to the sustainable nature of glass, these sheets can be recycled without degradation of properties, reducing the carbon footprint of industries reliant on glass products. Recycled float glass can seamlessly find new life in construction projects or even in the manufacture of new float glass, closing the loop of sustainability. Industry experts who have witnessed the evolution of float glass sheets underscore their role as a transformative force. Their extensive research and development efforts continue to innovate in areas such as coatings that enhance energy efficiency and surfaces that combat the transmission of harmful UV rays. These advancements not only enhance the functionality of glass but also reinforce its role in promoting global energy-saving goals. Trust in float glass sheets is ingrained in their long-standing reputation for reliability and performance. Long-time users of float glass vouch for its unwavering quality, which has famously stood unyielding against the elements, providing peace of mind for residential and commercial users alike. Such trust is backed by certifications and rigorous testing standards adhered to by manufacturers worldwide. End-users, from construction firms to automakers, rely on float glass for its adaptability and proven track record. With cutting-edge techniques and adherence to international safety and quality standards, float glass sheets continue to define what is possible in modern applications, sustaining their place as an invaluable material in industries relying on transparency and strength.

Next:

Latest news

-

What Is Float Glass- All You Need to Know

NewsJun.04,2025

-

How Is Tempered Glass Made?

NewsJun.04,2025

-

What is Tempered Glass and What It's Used For?

NewsJun.04,2025

-

Different Types of Tempered Glass: Choosing the Right Solution for Your Application

NewsJun.04,2025

-

What is the Difference Between Float Glass and Normal Glass?

NewsMay.30,2025

-

Differences Between Float Glass, Tempered Glass and Laminated Glass

NewsMay.29,2025

Related PRODUCTS