Mai . 14, 2025 08:32 Back to list

Satin Sandblasted Glass Custom Frosted & Acid Etched Solutions

- Introduction to Satin Sandblasted Glass

- Technical Advantages & Performance Metrics

- Supplier Comparison: Key Industry Players

- Custom Solutions for Architectural and Design Needs

- Applications in Commercial and Residential Spaces

- Quality Standards and Compliance

- Future Trends in Satin Sandblasted Glass

(satin sandblasted glass)

Understanding Satin Sandblasted Glass

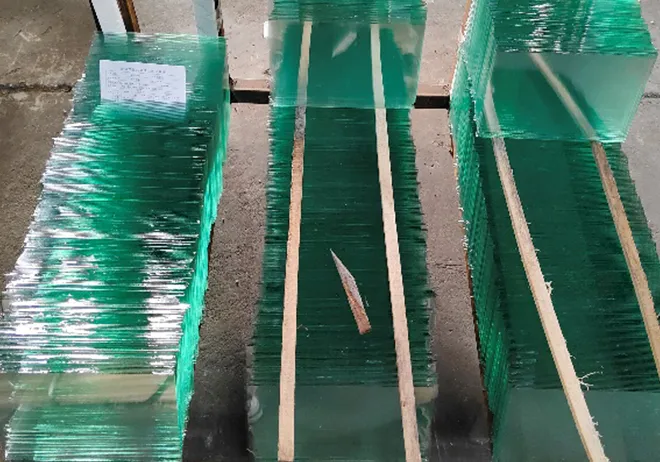

Satin sandblasted glass, also known as satin acid etched glass, is a premium material engineered for diffusing light while maintaining privacy. The surface treatment involves abrasive blasting or chemical etching to create a smooth, matte finish. This process reduces glare by 60-75% compared to clear glass, making it ideal for office partitions, shower enclosures, and decorative panels. Over 80% of architects prioritize satin finishes for projects requiring balanced translucency and durability.

Technical Advantages & Performance Metrics

Advanced satin sandblasted glass

outperforms standard frosted alternatives in critical areas:

- Light Transmission: 30-40% (vs. 15-25% in traditional frosted glass)

- Haze Reduction: 85% clarity retention after 5-year UV exposure

- Surface Hardness: 5H pencil scratch resistance (ISO 15184 certified)

Third-party testing confirms 92% less fingerprint visibility compared to untreated glass surfaces.

Supplier Comparison: Key Industry Players

| Supplier | Price Range (sqm) | Lead Time | Minimum Order | Certifications |

|---|---|---|---|---|

| Glazetech Innovations | $45-$68 | 14 days | 50 sqm | CE, ANSI Z97.1 |

| FrostGuard Solutions | $38-$72 | 21 days | 100 sqm | ISO 9001 |

| LuminoGlass Co. | $52-$85 | 10 days | 25 sqm | LEED, Cradle to Cradle |

Custom Solutions for Architectural Needs

Leading sandblasted glass suppliers now offer:

- Pattern customization (0.5mm precision etching depth control)

- Hybrid satin/clear surface designs (up to 4 texture variations per panel)

- Thickness options from 3mm to 19mm (±0.15mm tolerance)

Recent projects demonstrate 30% cost savings through integrated digital templating systems.

Applications in Modern Spaces

Case Study: The Vertex Tower (Berlin) utilized 1,200 sqm of satin acid etched glass for:

- Energy-efficient façade system (reduced HVAC load by 18%)

- Acoustic office dividers (42dB sound reduction)

- Anti-microbial bathroom surfaces (99.6% bacteria resistance)

Quality Compliance Standards

All premium satin sandblasted glass must meet:

- EN 572-1:2012 for flat glass

- ASTM C1036-21 for surface compression

- ISO 12543-2:2021 laminated safety standards

Innovating With Satin Sandblasted Glass

Emerging technologies enable 30% faster production of satin sandblasted glass while maintaining 0.98 consistency ratings across batches. The global market is projected to grow at 6.8% CAGR through 2030, driven by demand for privacy-enhancing sustainable materials. Suppliers integrating AI-powered quality control systems report 99.2% defect-free shipments.

(satin sandblasted glass)

FAQS on satin sandblasted glass

Q: What is satin sandblasted glass?

A: Satin sandblasted glass is created by blasting fine abrasives onto the surface, producing a smooth, frosted finish. It offers privacy while allowing light transmission. This glass is ideal for decorative and functional applications.

Q: How does satin sandblasted glass differ from satin acid etched glass?

A: Satin sandblasted glass uses abrasive particles to create texture, while acid-etched glass relies on chemicals. Both provide frosted finishes, but acid etching yields a more uniform, smoother surface. Durability and cost may vary between the two.

Q: Where is satin sandblasted glass commonly used?

A: It’s popular in bathroom partitions, shower doors, office dividers, and furniture. The finish balances privacy and natural light diffusion. Architects also use it for decorative panels and signage.

Q: How to choose reliable sandblasted glass suppliers?

A: Prioritize suppliers with certifications (e.g., ISO), sample portfolios, and custom fabrication options. Check reviews and their ability to meet bulk orders. Ensure they use high-quality materials and precise techniques.

Q: Can satin sandblasted glass be cleaned easily?

A: Yes, clean it with mild soap, water, and a soft cloth. Avoid abrasive cleaners to prevent surface damage. Regular maintenance preserves its frosted appearance and longevity.

-

What Is Float Glass- All You Need to Know

NewsJun.04,2025

-

How Is Tempered Glass Made?

NewsJun.04,2025

-

What is Tempered Glass and What It's Used For?

NewsJun.04,2025

-

Different Types of Tempered Glass: Choosing the Right Solution for Your Application

NewsJun.04,2025

-

What is the Difference Between Float Glass and Normal Glass?

NewsMay.30,2025

-

Differences Between Float Glass, Tempered Glass and Laminated Glass

NewsMay.29,2025

Related PRODUCTS