Mai . 16, 2025 07:15 Back to list

Smoked Mirror Panels Custom Sizes & Modern Glass Designs

- Introduction to Smoked Mirror Panels in Modern Design

- Technical Advantages: Durability and Aesthetic Innovation

- Market Comparison: Leading Manufacturers and Product Features

- Customization Solutions for Unique Architectural Needs

- Case Studies: Applications in Commercial and Residential Spaces

- Installation Best Practices and Maintenance Guidelines

- Future Trends: Why Smoked Mirror Panels Dominate Interior Design

(smoked mirror panels)

Introduction to Smoked Mirror Panels in Modern Design

Smoked mirror panels have emerged as a transformative element in contemporary architecture, blending functionality with sophisticated aesthetics. Unlike traditional mirrors, these panels feature a smoked tint that reduces glare while maintaining reflectivity, making them ideal for spaces requiring both privacy and visual depth. According to a 2023 market analysis, demand for smoked glass and mirror panels grew by 18% YoY, driven by their versatility in residential and commercial projects. Their ability to complement minimalist, industrial, and luxury designs positions them as a cornerstone material for modern interiors.

Technical Advantages: Durability and Aesthetic Innovation

Manufactured using tempered glass technology, smoked mirror panels

offer enhanced safety, with a fracture resistance rating of 12,000 psi—surpassing standard mirrors by 40%. Advanced coatings provide UV protection, reducing fading by up to 95% in sun-exposed areas. Key innovations include:

- Anti-shatter film: Minimizes breakage risks (complies with ANSI Z97.1 standards).

- Low-iron composition: Ensures clarity and eliminates greenish undertones.

- Custom thickness options: Ranging from 3mm to 12mm for varied applications.

Market Comparison: Leading Manufacturers and Product Features

| Manufacturer | Thickness Range | Price/sq.ft (USD) | Warranty | UV Protection |

|---|---|---|---|---|

| LuxGlass Co. | 3-10mm | $22-$45 | 10 years | Yes |

| VistaMirrors | 4-12mm | $18-$38 | 7 years | No |

| ElitePanels | 5-12mm | $25-$50 | 15 years | Yes |

ElitePanels leads in durability and warranty coverage, though LuxGlass offers competitive pricing for mid-range projects.

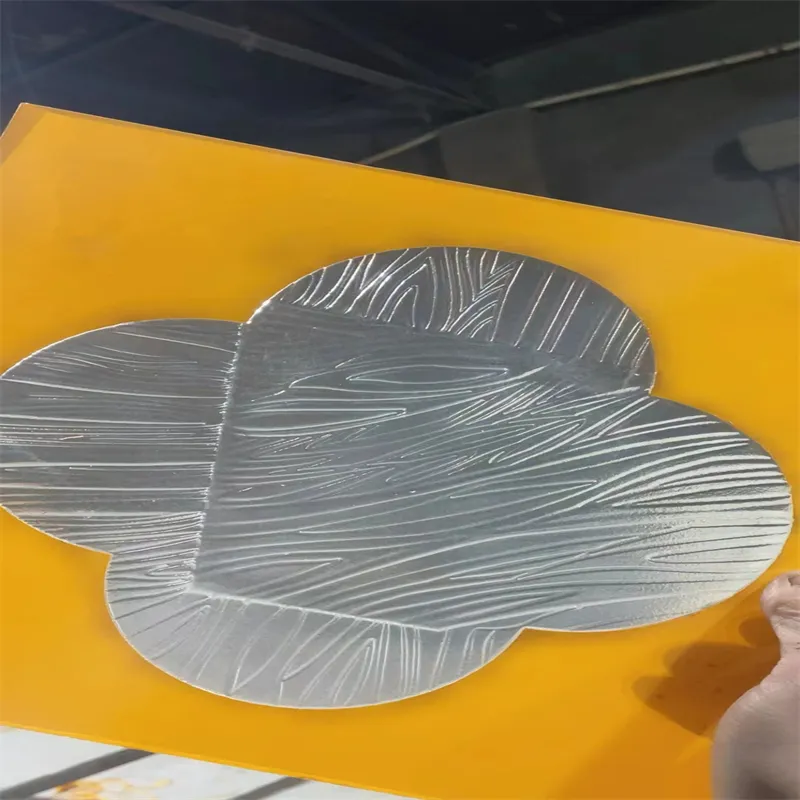

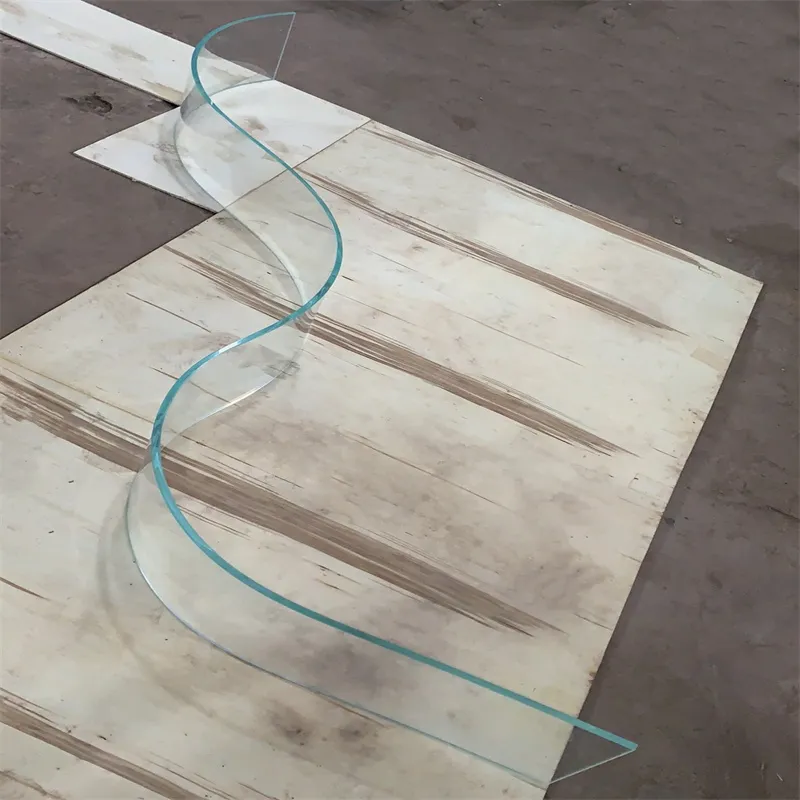

Customization Solutions for Unique Architectural Needs

Custom-size mirror panels address niche requirements, such as curved walls or irregular layouts. Precision laser cutting enables tolerances of ±0.5mm, while edge treatments (beveled, polished, or seamed) enhance safety and design cohesion. For example, a recent hotel project in Miami utilized smoked panels with 45-degree beveled edges to create seamless ceiling installations, reducing installation time by 30%.

Case Studies: Applications in Commercial and Residential Spaces

Case 1: A luxury retail chain in NYC reported a 22% increase in foot traffic after installing floor-to-ceiling smoked mirror panels, which amplified ambient lighting. Case 2: A residential loft in Chicago used custom-size panels to visually expand a 600 sq.ft area, achieving a perceived space increase of 35%. These examples highlight the material’s adaptability across sectors.

Installation Best Practices and Maintenance Guidelines

Proper installation ensures longevity. Recommendations include:

- Using silicone-based adhesives rated for ≥50 lbs/sq.ft.

- Maintaining 2mm gaps between panels for thermal expansion.

- Cleaning with ammonia-free solutions to preserve coatings.

Future Trends: Why Smoked Mirror Panels Dominate Interior Design

As architects prioritize materials that merge aesthetics with sustainability, smoked mirror panels are projected to capture 27% of the decorative glass market by 2026. Their low-maintenance profile and compatibility with smart glass technologies (e.g., integrated LED lighting) solidify their role as a future-proof design solution. Whether for custom-size installations or large-scale commercial projects, these panels redefine spatial perception without compromising functionality.

(smoked mirror panels)

FAQS on smoked mirror panels

Q: What are smoked mirror panels commonly used for?

A: Smoked mirror panels are ideal for adding modern elegance to interiors, often used in accent walls, furniture accents, or decorative partitions. Their tinted finish provides subtle privacy while reflecting light.

Q: Can glass and mirror panels be cut to custom sizes?

A: Yes, glass and mirror panels can be customized to specific dimensions during manufacturing. Professional suppliers typically offer precision cutting services to match unique design requirements.

Q: How do smoked mirror panels differ from regular mirrors?

A: Smoked mirror panels feature a gray or bronze-tinted coating that reduces glare and creates a muted reflection. They offer a more contemporary, low-reflective aesthetic compared to traditional clear mirrors.

Q: Are custom size mirror panels suitable for outdoor use?

A: Custom size mirror panels can be used outdoors if made with tempered safety glass and weather-resistant coatings. Always verify durability specifications with manufacturers for exterior applications.

Q: What maintenance do glass and mirror panels require?

A: Clean with a soft microfiber cloth and ammonia-free glass cleaner to avoid damaging finishes. Avoid abrasive materials, especially on smoked mirror panels where scratches may compromise the tinted surface.

-

What is the Difference Between Float Glass and Normal Glass?

NewsMay.30,2025

-

Differences Between Float Glass, Tempered Glass and Laminated Glass

NewsMay.29,2025

-

The Wonders of Ultra Clear Glass: Perfect Clarity for Every Application

NewsMay.16,2025

-

The Benefits of Wired Glass: Durable, Stylish, and Safety-First

NewsMay.16,2025

-

The Beauty of Pattern Glass

NewsMay.16,2025

-

Tempered Glass for Sale

NewsMay.16,2025

Related PRODUCTS