Floatglas

Was ist Floatglas?

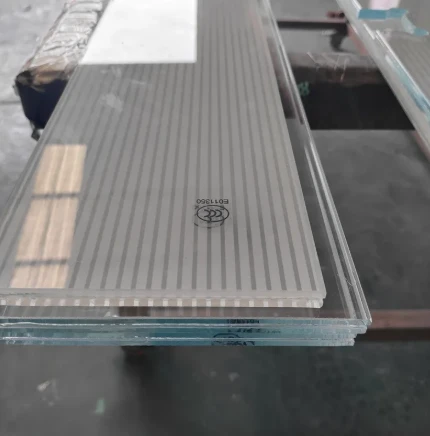

Floatglas, eine im Floatverfahren hergestellte Flachglasart, ist für seine gleichmäßige Dicke und glatte Ebenheit bekannt. Seine hervorragenden Eigenschaften machen es zum am häufigsten verwendeten Grundmaterial in der Glasindustrie. Ob im Bauwesen, in der Innenausstattung oder im Automobilsektor – Floatglas nimmt in zahlreichen Anwendungsbereichen eine führende Position ein.

Wie wird Floatglas hergestellt?

Rohstoffe und Schmelzen: Die wichtigsten Rohstoffe zur Herstellung von Floatglas sind Quarzsand, Soda, Feldspat und Dolomit, die in einem bestimmten Verhältnis gemischt und in einem Ofen auf 1600 °C erhitzt werden, um geschmolzenes Glas zu bilden.

Floatverfahren: Anschließend wird das geschmolzene Glas auf ein Zinnbad gegossen, wo es sich ausbreitet und eine glatte Schicht auf der Oberfläche des geschmolzenen Zinns bildet.

Tempern: Nach dem allmählichen Abkühlen und Tempern sind die Floatglasscheiben vollständig geformt.

Arten von Floatglas

Nach der Farbe kann Floatglas in klares Floatglas unterteilt werden, ultraklares Floatglas (low iron float glass), and getöntes Glas.

According to quality, float glass can be divided into the level of Q1(none for visible bubbles, distortions, or blemishes), Q2(has little number of bubbles, distortions, or blemishes), and Q3(there are obvious bubbles and other blemishes).

Float Glass Advantages

Glatte und flache Oberfläche: Durch das Floatverfahren wird dem Glas eine hohe Ebenheit und Glätte verliehen.

Körperliche Stärke: Diese Glasart verfügt über eine bessere physikalische Festigkeit als Flachglas, wodurch die Bruchgefahr beim Transport deutlich reduziert werden kann.

Uniform Thickness: Float glass maintains a consistent thickness throughout, meeting the needs of various applications.

Hohe Transparenz: Floatglas ist für seine hervorragenden optischen Eigenschaften und hohe Lichtdurchlässigkeit bekannt und bietet außergewöhnliche Klarheit. Insbesondere ultraklares Floatglas erreicht typischerweise eine Lichtdurchlässigkeit von über 91,5 %.

Niedrige Kosten: Der Produktionsprozess von Floatglas bietet die Vorteile der Kontinuität, hohen Automatisierung, hohen Materialausnutzungsrate und des relativ geringen Energieverbrauchs, wodurch die Kosten im Vergleich zu Flachglas bei der Produktion im großen Maßstab deutlich niedriger sind.

Float Glass Applications

As an excellent basic material, float glass is widely used in industries such as construction, decoration, automobiles, home appliance panels, and solar glass due to its advantages of high quality, low cost, and large production capacity.

Glasvorhangfassade: Float glass is processed into coated glass or tinted glass, which is often used in the curtain wall of commercial high-rise buildings, such as large office buildings, hotels, etc.

Glasfenster und -türen: In modern building design, float glass is widely used across almost every structure. For many street-side shops, glass doors and windows are commonly chosen to enhance visibility, showcasing the store’s interior layout and products more effectively. In residential homes, processed float glass is typically utilized, such as insulated glass units (IGUs) for better thermal insulation, frosted glass for an elegant decorative touch, and tempered glass for enhanced safety.

Autoglas: Bei Autoglas wird üblicherweise Floatglas der Qualitätsklasse Q1 gewählt, das gehärtet und laminiert ist, um ihm eine hohe Schlagfestigkeit und Bruchsicherheit zu verleihen und so die Sicherheit von Fahrer und Passagieren umfassend zu gewährleisten.

Spiegelglas: Der Spiegel ist aus hochwertigem Floatglas gefertigt und gewährleistet ein klares, unverzerrtes Bild mit hervorragender Reflexionsqualität.

Möbel- und Geräteplatten: Durch die Weiterverarbeitung von Floatglas können wir rückseitig lackiertes Glas, Milchglas, keramisches Frittierglas und andere Glasarten herstellen, die für den Einsatz in Möbel- und Geräteblenden geeignet sind.

Wählen Sie ShottGlass als Ihren hochwertigen Floatglas-Lieferanten

We offer float glass with different levels of transparency and colors, and all sizes and thicknesses are available. If you have any custom ideas, we can help you realize them with our professional processing capabilities. Just contact us today to get more information about float glass, and we have the best quality and float glass price for you.

Float Glass Specifications And Farben

|

Farben |

Klares Floatglas, Ultra Clear Glass, Getöntes Glas |

|

Größe |

Maximum size is 3300 mm*12000 mm, other sizes based on your needs |

|

Dicke |

1,1 mm, 1,2 mm, 1,3 mm, 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 19 mm usw. |

Wofür wird Floatglas verwendet?

Float glass isn’t just glass—it’s the silent hero shaping modern life. Imagine a material so versatile it becomes windows in skyscrapers, windshields in your car, and the sleek display protecting your smartphone. This is the magic of float glass: flawlessly flat, optically pure, and engineered for possibility.

Architecture’s Clear Canvas

In construction, float glass transforms spaces. It floods offices and homes with natural light while providing thermal efficiency through coatings like low-e. From towering curtain walls to minimalist storefronts, its strength and clarity make it the backbone of contemporary design. Architects leverage it for everything from energy-efficient glazing to striking structural elements—turning buildings into beacons of innovation.

Automotive Excellence, Inside and Out

Your vehicle relies on float glass for safety and performance. As windshields, it’s laminated for impact resistance; as side windows, it’s tempered to shatter safely. Beyond visibility, it reduces noise and UV exposure, enhancing comfort on every journey. Electric vehicles even integrate it into panoramic roofs, merging durability with aesthetic appeal.

Interiors Reimagined

Step inside any modern space, and float glass defines the experience. It’s elegant shower enclosures resisting steam, seamless retail displays showcasing products, and sturdy tabletops combining form with function. Designers choose it for its adaptability—whether frosted for privacy or tinted for style, it elevates everyday environments.

Specialized Applications: Where Precision Matters

Float glass goes beyond the obvious. It’s the base for mirrors, the substrate for solar panels, and the essential layer in touchscreens. Laboratories use it for optically superior lenses, while appliances incorporate it for scratch-resistant oven doors. Its purity enables innovations in tech, renewable energy, and scientific instrumentation.

Why Trust Our Float Glass?

Crafted with advanced manufacturing, our float glass delivers consistency you can see. We prioritize optical clarity, minimal distortion, and customizable thickness (2mm to 19mm) for any project. Partner with us for material that isn’t just transparent—it’s transformative.

Build Clearer. Design Smarter.

From blueprint to finished product, float glass turns vision into reality. Discover how our solutions can elevate your next project—because when clarity matters, the foundation is everything.

Float Glass Process

At Shottglass, we believe that excellence starts at the foundation—and in the world of modern glassmaking, that foundation is the float glass process. Recognized globally as the gold standard for producing flat glass, this method ensures clarity, uniformity, and flawless finish in every sheet.

The float glass process begins by melting a precise mix of raw materials—primarily silica sand, soda ash, and limestone—at temperatures exceeding 1,500°C. Once liquefied, the molten glass flows gently onto a bath of molten tin in a carefully controlled atmosphere. Here, gravity and surface tension work in harmony to create a perfectly flat surface, eliminating the need for polishing or grinding.

As the glass glides across the tin bath, it gradually cools and solidifies into a continuous ribbon with an even thickness. It then enters the annealing lehr, a long heated tunnel that slowly reduces the temperature to prevent internal stresses and ensure the structural integrity of the glass. The result? Glass with outstanding optical clarity, smooth surfaces, and consistent thickness across every inch.

At Shottglass, we go beyond just the basics. Our state-of-the-art facilities apply decades of technical expertise to fine-tune each stage of the float glass process. From controlling particle size and purity in our raw materials to applying advanced coatings for UV protection, energy efficiency, or decorative finishes, every detail is engineered with purpose.

Our float glass is trusted across industries—from high-rise architecture and automotive windshields to furniture, interiors, and solar applications. Whether you need ultra-clear low-iron glass for a luxury storefront or tinted solutions for solar control, Shottglass delivers performance and quality you can see and feel.

Sustainability is also at the core of what we do. The float process is not only energy-efficient but also produces minimal waste. We recycle a large portion of glass cullet back into the production cycle, significantly reducing our environmental footprint.

Choose Shottglass for your next project and experience the precision, strength, and beauty only the finest float glass process can deliver. From raw material to refined sheet—clarity begins here.

Float Glass vs Clear Glass

When selecting the right type of glass for your construction or interior design project, one of the most common questions people ask is: What’s the difference between float glass and clear glass? While the terms are often used interchangeably, understanding the subtle distinctions can help you make a more informed, cost-effective choice.

Float glass is the most widely used form of flat glass today, and it gets its name from the unique manufacturing process. In this method, molten glass is poured onto a bed of molten tin, where it spreads out and forms a perfectly flat surface with uniform thickness. The result? A smooth, distortion-free glass ideal for windows, doors, mirrors, and facades. This technique gives float glass excellent optical clarity, strength, and a highly polished surface on both sides.

On the other hand, clear glass refers to the general appearance of the glass, specifically glass that doesn’t have a noticeable tint. In most cases, clear glass is actually float glass, but the key difference lies in the clarity. Standard float glass can have a slight greenish tint due to the natural iron content in the raw materials. This is still considered “clear” by most standards. However, for ultra-clear applications—like high-end display cases or luxury storefronts—you might opt for low-iron glass, which offers exceptional transparency without the green tint.

So, when you’re comparing float glass vs clear glass, it’s not a matter of choosing between two different products—it’s about understanding your project’s needs. For general residential and commercial glazing, standard float (or clear) glass is more than sufficient. But for high-visibility, precision-driven designs, you might want to look into low-iron float glass options for a truer “clear” effect.

When it comes to architectural precision, interior design, or even industrial use, understanding the difference between float glass and flat glass isn’t just technical—it’s essential. At Shottglass, we believe clarity should start with the material itself.

Float glass is a high-performance glass produced by floating molten glass on a bed of molten tin. This advanced method, used globally since the mid-20th century, ensures that the glass surface is incredibly smooth, uniform in thickness, and optically clear. For windows, facades, glass partitions, and even tabletops, float glass delivers both aesthetic appeal and structural integrity.

Flat glass, on the other hand, is a broader term. It refers to any glass manufactured in flat sheets, including float glass, but also includes older types such as drawn glass or rolled plate glass. While all float glass is flat, not all flat glass is float-quality. This distinction matters when you're comparing cost versus clarity, or aesthetics versus functionality.

At Shottglass, we specialize in manufacturing premium-grade float glass that meets the highest standards of flatness, transparency, and durability. Whether you're working on a sleek commercial tower or a minimalist residential project, our float glass offers unmatched performance. It’s ideal for further processing—laminating, tempering, coating, or insulating—making it the foundation of modern glazing systems.

Our flat glass offerings are suited for cost-effective applications where precision is less critical but safety and usability still matter. Think picture frames, cabinet doors, or greenhouses—places where utility comes first, but appearance still counts.

Choosing between float glass vs flat glass depends on your project’s purpose. But when quality, reliability, and visual clarity are non-negotiable, float glass from Shottglass is the clear winner. Every panel is produced with exacting care, giving architects, designers, and builders a product they can trust.

Let Shottglass help you see the difference—because it’s not just glass. It’s the surface between your vision and reality.

-

24Jun

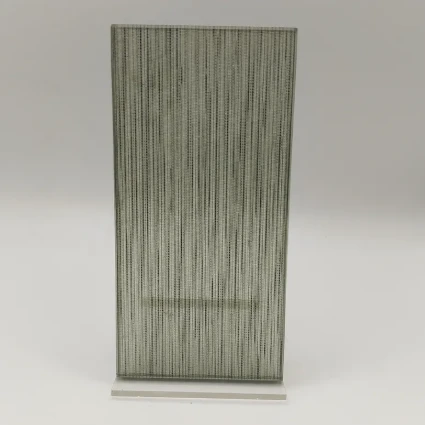

24JunSafety and Style with Premium Laminated Glass Solutions

ShottGlass continues to set the industry benchmark with its high-quality laminated glass offerings, serving customers worldwide who demand superior performance, elegant design, and unmatched safety.

Mehr erfahren -

24Jun

24JunReinvents Security with Premium Wired Glass

In today’s high-security environments, safety and transparency must go hand in hand.

Mehr erfahren -

24Jun

24JunPremium Float Glass Line for Modern Architecture

As construction and design industries continue to evolve, so does the demand for clarity, strength, and innovation in building materials.

Mehr erfahren