Oct . 06, 2024 16:37 Back to list

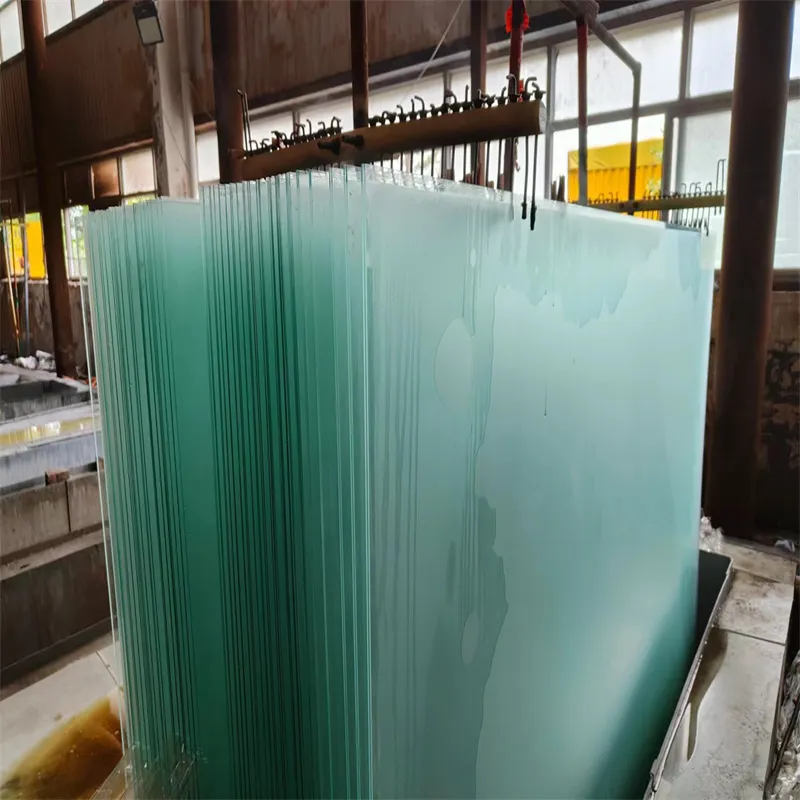

15mm float glass

Exploring the Characteristics and Applications of 15mm Float Glass

Float glass, a widely used form of glass characterized by its smooth and uniform surface, has become an essential material in various industries. Among the multiple thicknesses available, 15mm float glass stands out due to its unique properties and versatility. This article delves into the characteristics, manufacturing process, advantages, and applications of 15mm float glass.

Characteristics of 15mm Float Glass

15mm float glass is notable for its impressive optical clarity, flatness, and durability. The thickness of the glass provides a substantial degree of strength, making it suitable for applications where robustness is essential. The glass typically has a light transmittance of over 90%, allowing natural light to infiltrate while maintaining visibility. Furthermore, the uniform thickness ensures that light is distributed evenly, reducing distortion and enhancing visual quality.

In addition to its optical properties, 15mm float glass showcases excellent thermal performance. It has a low thermal expansion coefficient, which means it can withstand significant temperature fluctuations without warping or breaking. This makes it an ideal choice for buildings and structures that face diverse weather conditions.

Manufacturing Process

The process of manufacturing float glass was developed in the mid-20th century and remains largely unchanged. It begins with melting a mixture of silica sand, soda ash, and limestone at high temperatures. The molten glass is then poured onto a bed of molten tin, where it spreads out to form a flat sheet. The use of tin is crucial as it allows the glass to float, resulting in a perfectly smooth surface on both sides.

Once the glass has cooled and solidified into sheets, it is cut to size and subjected to quality control measures to ensure that it meets industry standards for clarity and uniformity. Additional treatments, such as annealing, can also be applied to enhance its strength and thermal resistance.

Advantages of 15mm Float Glass

15mm float glass

One of the primary advantages of 15mm float glass is its strength and safety

. The thickness provides added durability, making it less susceptible to breakage compared to thinner varieties. This characteristic is especially beneficial in safety glass applications, where the risk of shattering needs to be minimized.Moreover, 15mm float glass offers excellent sound insulation properties. As an effective barrier against noise pollution, it is often used in buildings located in high-traffic areas or near airports. When combined with other acoustic treatments, it can significantly improve the interior sound environment.

Another notable benefit is the aesthetic appeal of 15mm float glass. Its clarity and smoothness contribute to modern architectural designs, providing elegance to facades, windows, and interiors. The glass can be easily treated with various coatings to enhance its energy efficiency, reflectivity, or even color, adapting it to specific design needs.

Applications of 15mm Float Glass

The applications of 15mm float glass are vast and varied. In the construction industry, it is widely used in facades, curtain walls, and large windows, where both strength and aesthetics are crucial. Its robustness makes it suitable for use in high-rise buildings, ensuring structural integrity and safety.

In addition to architectural uses, 15mm float glass is prevalent in the automotive sector. It is often employed in windshield and window production, providing both clarity and safety for vehicles. The glass can be further processed to meet regulatory standards for impact resistance.

Furthermore, 15mm float glass is utilized in furniture design, such as tables and shelves, due to its ability to combine elegance with function. Designers appreciate its transparency, allowing for creative designs that emphasize minimalism and lightness.

Conclusion

Overall, 15mm float glass is a remarkable material that combines strength, safety, and aesthetic appeal. Its unique properties, stemming from the float glass manufacturing process, make it versatile for various applications across industries. Whether in construction, automotive, or interior design, 15mm float glass continues to play a vital role, marking its significance in our built environment. As technology advances, we can anticipate even more innovative uses for this essential material in the future.

-

Mirror Glass: A Multifunctional Material in the Interweaving of Light and Shadow

NewsAug.20,2025

-

Laminated Glass: A Special Material That Safeguards Safety and Transparency

NewsAug.20,2025

-

Insulated Glass: The Ideal Choice for Building Energy Efficiency

NewsAug.20,2025

-

Frosted Glass: The Perfect Fusion of Hazy Aesthetics and Practical Functionality

NewsAug.20,2025

-

Coated Glass: A Fusion of Functionality and Aesthetics in Modern Decoration

NewsAug.20,2025

-

Clear Float Glass: A Transparent Aesthetic Carrier in Modern Decoration

NewsAug.20,2025

Related PRODUCTS