Coated Glass

-

Made by chemical etching method, our AG glass (anti-glare glass) is ofen used in photo frame, minitor and screens. AR glass(anti-reflective glass) is made by magnetron sputtering method. Both AG glass and AR glass can be customized from 1.3mm-10mm thickness, and size as large as 2000*2800mm

-

Anti-reflective glass (AR glass) is a kind of coated glass with great light transmission and reflection control properties. It is normally produced by coating on one or both surfaces of float glass with an advanced magnetron sputtering technology. Using low-iron glass as the base glass to make anti-reflective glass will achieve a better effect.

-

Reflective glass is a kind of coated glass.It is usually coated with one or more layers of metal or metal compound films on the surface of the glass to change the optical properties of the glass and meet certain specific requirements. This coating allows the glass to reflect light and images while still allowing some degree of transparency from the other side. It can be coating on the surface of clear or tinted glass.

-

Low-emissivity glass normally refers to low-e glass, is one type of coated glass which is designed for energy controlling. Its coating layer has the characteristics of high transmission of visible light and high reflection of infrared rays. Therefore, it is widely used as an energy-efficient glass in doors and windows of buildings. There are currently two main production methods, online high-temperature pyrolytic deposition (online production) and offline vacuum magnetron sputtering (offline production).

-

Coated glass is a kind of glass with one or more layers of special film applied on the glass surface by magnetron sputtering or other processing methods. It not only achieves an effect of energy efficiency but also presents an aesthetic appeal. This makes it ideal for modern construction, the automotive industry, and other applications.

-

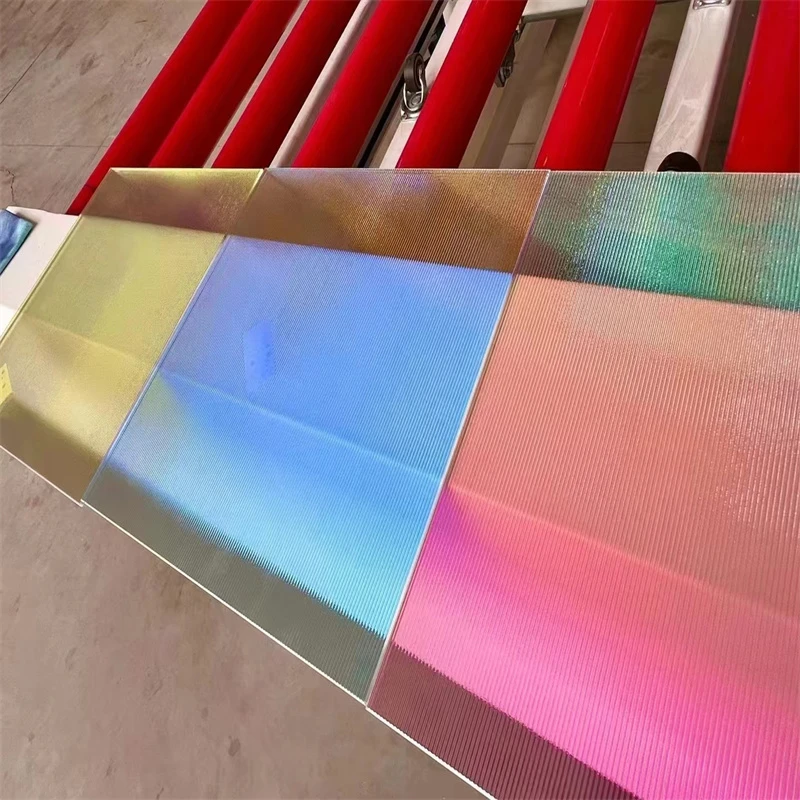

Dichroic glass is a type of glass with special optical properties. It is made by coating the glass surface with multiple layers of metal oxides using magnetron sputtering technology. By varying the thickness and composition of each layer, we can allow certain wavelengths of light to reflect off the glass surface while allowing other wavelengths of light to pass through the glass.