Sep . 22, 2024 05:34 Back to list

low iron glass price

The Market Trends of Low Iron Glass Understanding Prices and Factors Influencing Them

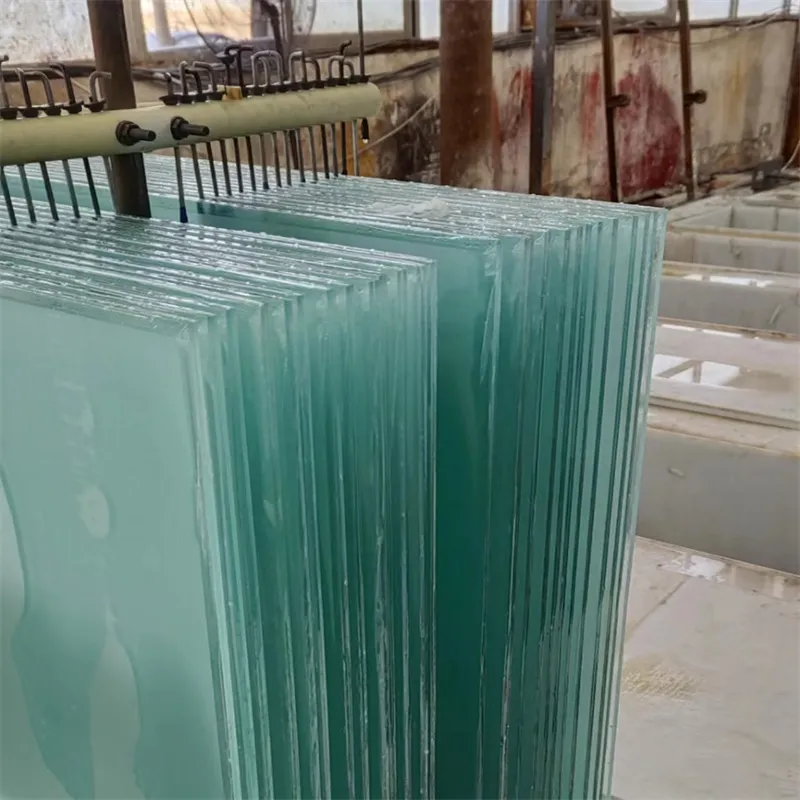

Low iron glass, often referred to as ultra-clear glass, is celebrated for its exceptional optical clarity, making it a preferred choice in various applications, from architecture to solar panels. As the demand for aesthetically pleasing and high-performance materials continues to rise, understanding the pricing dynamics of low iron glass becomes crucial for both manufacturers and consumers. This article delves into the factors influencing the prices of low iron glass and the current market trends.

What is Low Iron Glass?

Low iron glass is produced using raw materials that have minimal iron content, resulting in a glass that is nearly colorless and transparent. This unique property allows for maximum light transmission and minimal distortion, making low iron glass highly desirable for high-end applications such as luxury buildings, showcases, and modern interior designs. Additionally, its applications in solar energy technologies are driving its demand further, as efficiency is directly tied to the quality of glass used.

Current Pricing Trends

As of late 2023, the price of low iron glass has seen fluctuations primarily due to changes in raw material costs, manufacturing processes, and global demand. Prices typically range from $2 to $10 per square foot depending on various factors such as thickness, treatment, and supplier. For standard low iron glass, prices hover around $4 to $6 per square foot. However, custom sizes or specially treated glass can fetch significantly higher prices.

Influencing Factors

1. Raw Material Costs The cost of silica sand and other raw materials significantly impacts low iron glass pricing. Prices of these materials can vary based on geopolitical factors and supply chain disruptions.

low iron glass price

2. Production Capacity The availability of production facilities and their capacity to manufacture low iron glass can affect pricing. When production facilities operate at capacity, prices may stabilize or decrease due to economies of scale.

3. Technological Advances Innovations in glass manufacturing processes can lead to more cost-effective production methods. However, initial investments in new technologies can lead to temporary price increases.

4. Market Demand and Supply The demand for low iron glass, particularly in construction and renewable energy sectors, has been on the rise. This increased demand, coupled with limited supply due to production constraints, can drive prices higher.

5. Environmental Regulations Stricter regulations regarding production processes and waste management can impact manufacturing costs. Companies may pass these costs onto consumers, influencing retail prices.

6. Consumer Preferences As consumers become more eco-conscious, there is a growing preference for sustainable materials. Low iron glass, being recyclable and energy-efficient, has garnered interest, thus affecting its market value.

Conclusion

In summary, the pricing of low iron glass is a complex interplay of various factors, including raw material costs, production efficiencies, and market dynamics. As demand continues to grow in sectors like architecture and renewable energy, monitoring these trends is essential for stakeholders. By understanding the underlying forces at play, manufacturers and consumers alike can make informed decisions in the evolving landscape of low iron glass pricing. As we move forward, it will be crucial to keep an eye on the innovations and market shifts that will shape the future of this distinctive glass type.

-

Mirror Glass: A Multifunctional Material in the Interweaving of Light and Shadow

NewsAug.20,2025

-

Laminated Glass: A Special Material That Safeguards Safety and Transparency

NewsAug.20,2025

-

Insulated Glass: The Ideal Choice for Building Energy Efficiency

NewsAug.20,2025

-

Frosted Glass: The Perfect Fusion of Hazy Aesthetics and Practical Functionality

NewsAug.20,2025

-

Coated Glass: A Fusion of Functionality and Aesthetics in Modern Decoration

NewsAug.20,2025

-

Clear Float Glass: A Transparent Aesthetic Carrier in Modern Decoration

NewsAug.20,2025

Related PRODUCTS