Sep . 28, 2024 18:28 Back to list

Durable Safety Glass Solutions for Enhanced Strength and Impact Resistance in Modern Architecture

The Evolution and Applications of Toughened Float Glass

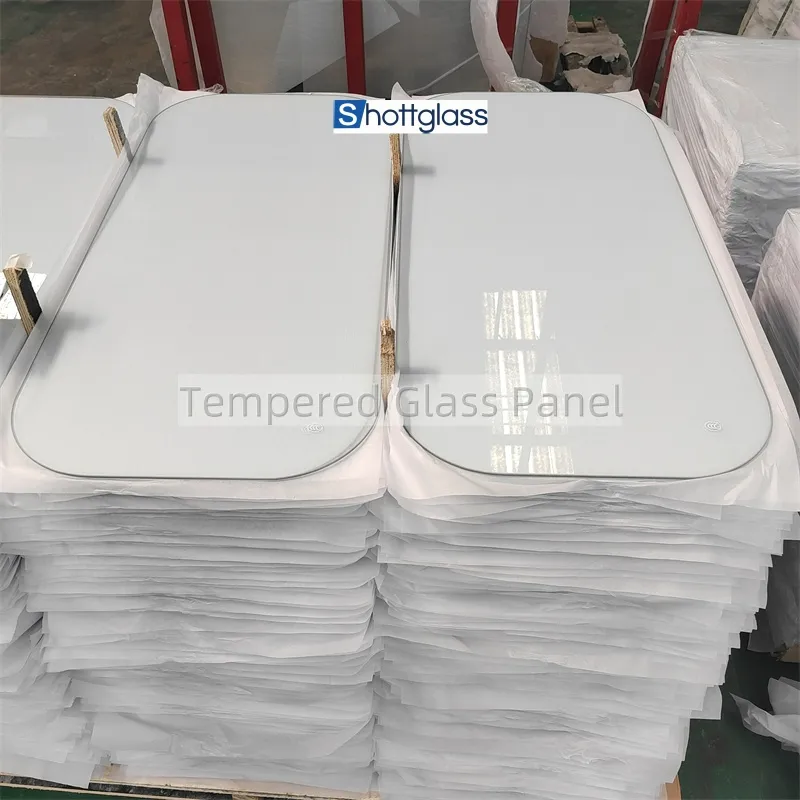

Toughened float glass, commonly referred to as tempered glass, has emerged as an indispensable material in a variety of industries due to its remarkable strength and safety features. Understanding the properties, manufacturing process, and diverse applications of toughened float glass reveals its pivotal role in modern architecture, automotive, and even household products.

What is Toughened Float Glass?

Toughened float glass begins its life as standard float glass, which is produced by floating molten glass on a layer of molten tin. This process creates a smooth, uniform surface and ensures optical clarity. The transformation into toughened glass involves a heat treatment process. Once the float glass is cut to the desired dimensions, it is heated to approximately 620°C and then rapidly cooled. This thermal tempering process alters the internal structure of the glass, creating compressive stresses on the surface which enhance its strength and resilience significantly.

One of the defining characteristics of toughened float glass is its impact resistance. It can withstand greater forces than standard glass and is less likely to break under mechanical stress. When it does shatter, it breaks into small, blunt pieces rather than sharp shards, minimizing the risk of injury. This safety feature makes toughened glass particularly valuable in public and domestic settings.

Applications in Architecture and Construction

In the realm of architecture, toughened float glass is commonly used in windows, facades, and glass doors

. It offers a sleek aesthetic while providing thermal insulation and UV protection. Moreover, its strength allows for larger panes of glass to be used without the need for excessive framework, creating an open and airy feel in commercial and residential buildings.Architects also appreciate toughened glass for its durability in high-rise structures. It can withstand extreme weather conditions, including high winds, hail, and varying temperatures, which extends the lifespan of the building components. Fire-rated toughened glass is also employed in buildings to fulfill safety regulations, providing an effective barrier against fire spread while allowing light to enter.

toughened float glass

Toughened Glass in the Automotive Industry

The automotive industry utilizes toughened float glass for a multitude of applications, including windshields, side windows, and rear windows. The strength and safety features of tempered glass are particularly critical in vehicles, where impact resistance is essential for passenger safety. In the event of an accident, the toughened glass is less likely to shatter into dangerous shards, protecting occupants from injury.

Furthermore, toughened glass helps improve the structural integrity of vehicles. Its lightweight nature contributes to better fuel efficiency, and advancements in glass technology lead to reduced vehicle weight without compromising safety. As innovation continues in the automotive sector, the demand for high-performance toughened glass is expected to rise, particularly with the growth of electric and autonomous vehicles.

Domestic and Commercial Uses

In addition to architecture and automotive applications, toughened float glass is also prevalent in various domestic and commercial products. Shower enclosures, glass tables, and countertops often incorporate toughened glass for both aesthetic appeal and practical safety. In kitchens and bathrooms, where humidity and temperature fluctuations are common, toughened glass’s thermal resistance is particularly beneficial.

Retail environments increasingly use toughened glass displays and partitions. Not only does it enhance the visibility of products, but its durability also stands up to the regular wear and tear that retail spaces experience. Security glazing, made from multiple layers of glass, often utilizes toughened float glass to provide resistance against forced entry or vandalism.

Conclusion

Toughened float glass represents a remarkable advancement in materials technology, blending aesthetic appeal with functional strength and safety. From architectural marvels to critical automotive components and everyday domestic items, its versatility and resilience have established it as a cornerstone in various sectors. As industries continue to innovate and prioritize safety, the future of toughened glass looks promising, paving the way for new applications and enhanced designs that can meet the complex challenges of the modern world.

-

Sustainable Practices in a Modern Coated Glass Factory

NewsAug.07,2025

-

Insulated Glass Unit Installation Best Practices and Tips

NewsAug.07,2025

-

Frosted Glass Types and Custom Solutions for Sale

NewsAug.07,2025

-

Current Clear Float Glass Price Trends in Global Markets

NewsAug.07,2025

-

Comparing Different Types of Laminated Glass Performance

NewsAug.07,2025

-

Best Anti Fog Bathroom Mirror Solutions for Humid Climates

NewsAug.07,2025

Related PRODUCTS