Insulated Glass

The main materials needed to make an insulated glass unit are two or more pieces of high-quality flat glass, aluminum alloy frame, spacer bar, desiccant, sealant, etc. Depending on the number of glass sheets installed on every insulating glass unit, we can produce double glazing, triple glazing, quadruple glazing.

To make double glazing: Two pieces of flat glass and the spacer are sealed in the aluminum frame with a special composite adhesive to form a sealed dry space (air player) between the glass, thus achieving the effect of sound insulation and heat insulation.

To make triple glazing: As the name suggests, we need three pieces of flat glass and two sets of spacers. The three pieces of glass are separated into two spaces (air player), which provide better insulation than double glazing.

To make quadruple glazing: By using four pieces of flat glass we can manufacture quadruple glazing, which will create three spaces (air player) between the four pieces of glass. Quadruple glazing is normally used in some places that have a special requirement for insulation.

There are multiple types of glass we can choose to use in IGUs, such as clear float glass, tinted glass, reflective glass, low-e glass, patterned glass, tempered glass, and laminated glass. IGUs made from different types of glass will produce different insulation effects. Therefore, the mainstream insulated glass has the following types:

Float insulated glass: Use clear float glass to make ordinary grade insulated glass (click here to learn more about Clear Float Glass).

Reflective insulated glass:The insulation effect is stronger than single-piece reflective glass(click here to learn more about Reflective Glass ).

Low Emissivity insulated glass:Have a better insulation effect than single-piece Low-E glass (click here to learn more about Low Emissivity Glass).

Tempered insulated glass: It has greatly improved the impact resistance of the product. As a safety insulating glass, it is widely used in contemporary energy-saving buildings(click here to learn more about Tempered Glass).

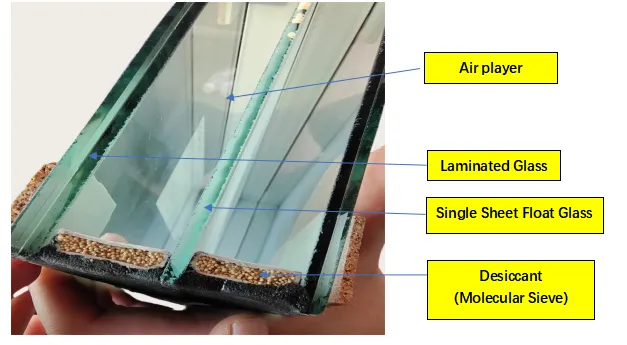

Laminated insulated glass: This is also a type of safety insulated glass that can achieve excellent sound insulation and heat insulation effects (click here to learn more about Laminated Glass).

A Laminated Insulated Glass Unit

Besides the panes, the air layer plays a very important role in thermal insulation. The air layer of a regular IGU is filled with air, which provides a certain level of thermal insulation at a relatively low cost. On the other hand, if we want to achieve better thermal insulation, the common practice is to replace the ordinary air with argon or krypton.

Insulating glass units (IGUs) are primarily used in the external structures of buildings, such as windows and curtain walls. They are commonly installed in residential, commercial, and public buildings, including apartments, hotels, hospitals, office buildings, and schools, to enhance energy efficiency. Additionally, IGUs are frequently utilized in the doors and windows of transportation vehicles like trains and ships, contributing to overall energy conservation in these applications.

Heat insulation: Reducing the inflow of outdoor heat and preventing the outflow of indoor heat are key benefits of Insulated Glass Units (IGUs). These units help maintain a comfortable indoor temperature by keeping most of the outdoor heat at bay during summer, ensuring a cool indoor environment. In winter, they minimize indoor heat loss, creating a warm and cozy living space.

Noise insulation: IGUs also excel in noise insulation, particularly laminated insulated glass, which can block up to 42 decibels of noise, significantly reducing the impact of outdoor noise on indoor environments.

Transmittance: IGUs provide insulation while allowing natural light to flow through, enhancing indoor lighting.

Generally, an IGU is composed of several pieces of glass of the same thickness. However, if there is a special purpose, an IGU can also be made with glass of different thicknesses. The following are some specifications:

|

Glass size |

600mm*900mm,800mm*1100mm,900mm*1300mm, 1016mm*1220mm, 1000mm*1500mm,1500mm*2000mm, etc. |

|

Glass thickness |

4mm, 5mm, 6mm,8mm, etc. |

|

Air player thickness |

9mm-15mm |

|

Frame thickness |

6mm-12mm |

Laminated insulated glass dimensions: (5+0.38pvb+5)+9A+6, (6+0.76pvb+6)+12A+(5+0.76pvb+5), (8+1.52pvb+8)+12A+(6+1.52pvb+6), etc. (Units: mm, A refers to Air Player)

ShottGlass has established a comprehensive production line for insulated glass, capable of manufacturing various types of insulated glass. To meet the growing market demand, we are equipped with advanced production equipment, including an automatic glass cutting line, a double bent bi-directional glass tempering furnace, a magnetron sputtering line, an automatic insulated glass production line, and more.

Through years of exploration, we have accumulated extensive manufacturing experience. We strictly control the quality of each stage in the production process, ensuring precise glass cutting, complete structural sealant application, and airtight air layers. Our high-quality products have earned widespread trust and support from our customers. If you have any needs or questions regarding insulated glass, please contact us for more product information.

-

07Aug

07AugSustainable Practices in a Modern Coated Glass Factory

As environmental consciousness reshapes industrial standards, the coated glass sector is evolving to meet new sustainability demands.

learn more -

07Aug

07AugInsulated Glass Unit Installation Best Practices and Tips

In the competitive market of glass products, understanding the ins and outs of insulated glass unit is crucial for wholesalers.

learn more -

07Aug

07AugFrosted Glass Types and Custom Solutions for Sale

In the ever - evolving realm of architectural and decorative materials, frosted glass has firmly established itself as a versatile and indispensable choice.

learn more