Jul . 31, 2025 05:40 Back to list

Advanced Blue Coated Glass: Energy Efficient & AI-Optimized

Blue coated glass and its variants have become central to modern architectural, industrial, and high-precision optical sectors. In this comprehensive guide, we explore the specifications, manufacturing process, applications, custom solutions, and market trends for blue coated glass, referencing real industry standards and case studies to empower purchasing decisions with facts and transparency.

1. Understanding Coated Glass: Definition Industry Trends 2024

Coated glass refers to flat or shaped glass that has been treated with nanoscale thin-film layers during production via vacuum plating, magnetron sputtering, or chemical vapor deposition (CVD). These coatings improve characteristics such as reflectivity, thermal and UV insulation, color, and optical transmission.

- blue coated glass meaning: Glass that exhibits a blue hue due to titanium, cobalt, or chromium oxide thin-film layers, widely used in architecture for both aesthetics and solar control.

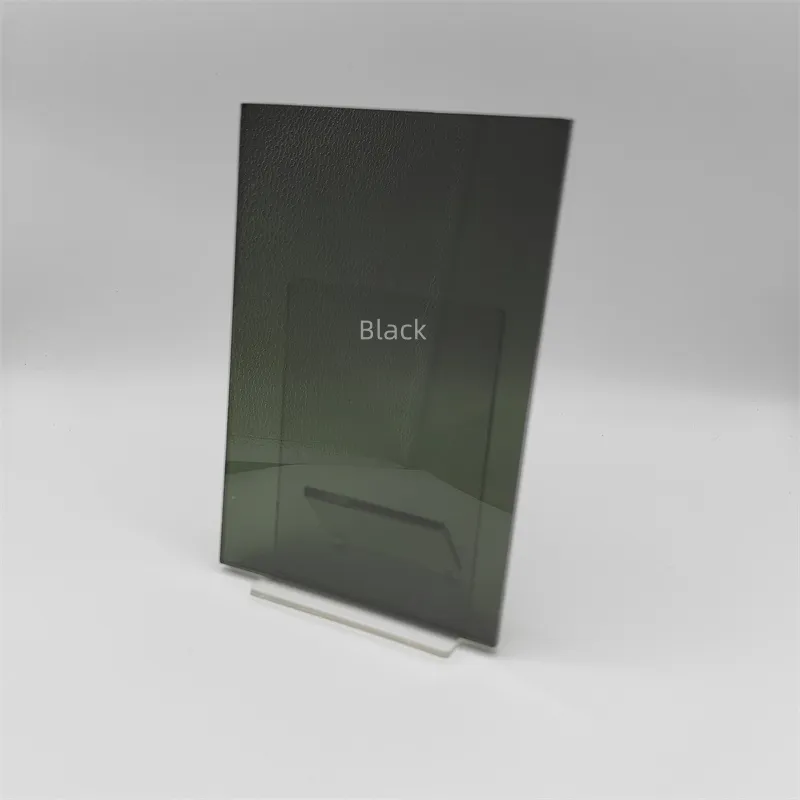

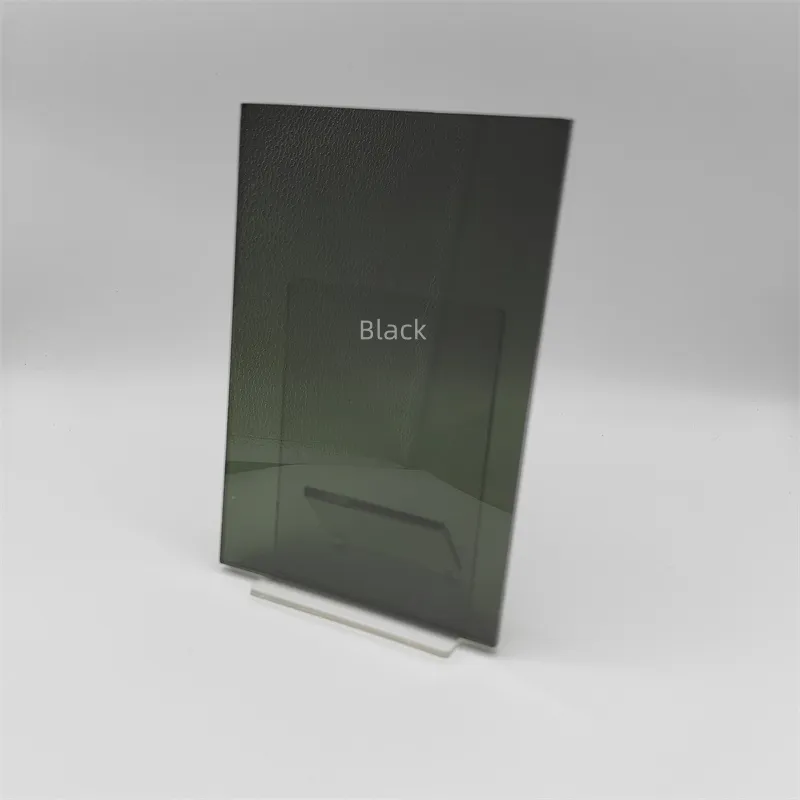

- black coated glass: Achieves deep absorption properties, suitable for privacy and solar gain control.

2. Blue Coated Glass Manufacturing Process: Step-by-Step Diagram

→

→

→

→

→

→

- Raw Glass Selection: Use of high-purity silica float glass as substrate, ISO 9050 compliant.

- Cleaning & Pre-Treatment: Surface cleaning (deionized water + scrubbing rollers), alkaline/acidic pretreatment to remove micro-contaminants.

- Vacuum Coating (Magnetron Sputtering): Deposition of metal-oxide (TiO₂, SiO₂, ZnO, CoO) layers up to 300nm via controlled vacuum. Ensures uniform blue tint and optimal reflectance/transmittance.

- Heat Treatment (as required): Tempering or annealing improves mechanical and thermal durability.

- Inspection & Cutting: Automated vision system (CCD camera) checks coating uniformity (ISO 28278-2); defective panels are rejected.

- Packing & Shipping: Vacuum-sealed or paper interleaving prevents surface scratches.

Manufacturing Flow (Simplified):

- Material: Float glass (SiO₂ ≥ 72%)

- Main Machinery: Magnetron Sputtering Line, CNC Glass Cutting, Annealing/Tempering Furnace

- Certifications: ISO 9001, ISO 12543 (safety), ANSI Z97.1 (impact resistance)

3. Technical Parameters: Product Specifications & Industry Data

| Feature | Specification | Test Standard |

|---|---|---|

| Thickness | 4 mm / 5 mm / 6 mm / 8 mm / 10 mm / 12 mm | EN 572-2 |

| Visible Light Transmittance | 36% – 48% (for 6mm) | ISO 9050:2003 |

| UV Blocking | ≥ 84% (for 6mm) | EN 410 |

| Solar Factor (g-value) | 0.39 ~ 0.42 | ISO 52022-3 |

| Surface Hardness | ≥ 6H pencil | ASTM D3363 |

| Color Uniformity ΔE | < 1.2 (excellent) | ISO 11664-4 |

| Service Life | ≥ 20 years (exterior facade) | ASTM C1036/1048 |

| Environmental Compliance | RoHS / REACH / EU CE / SGS | CE EN 12150 |

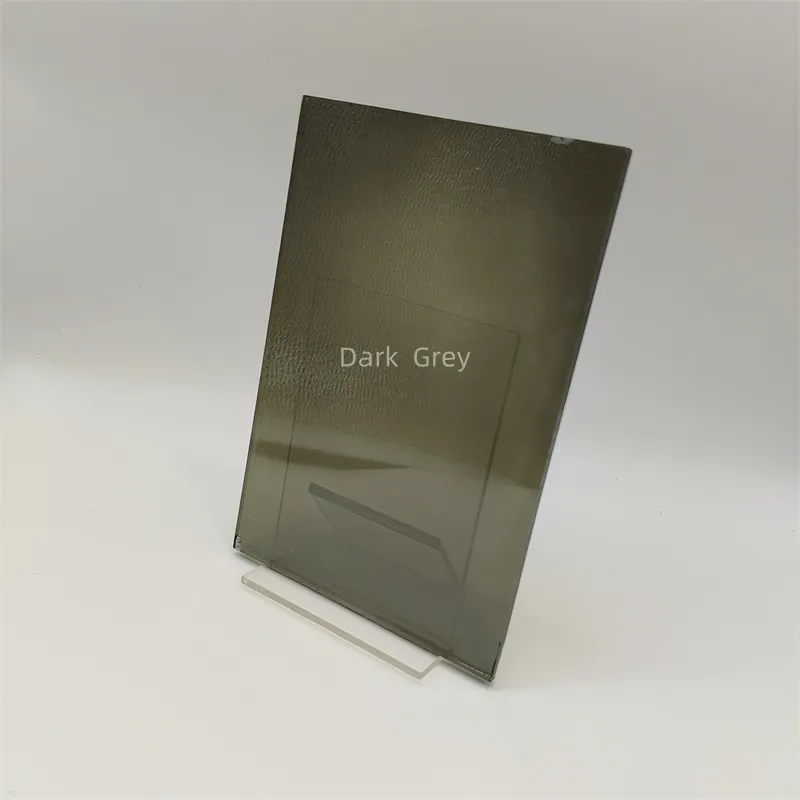

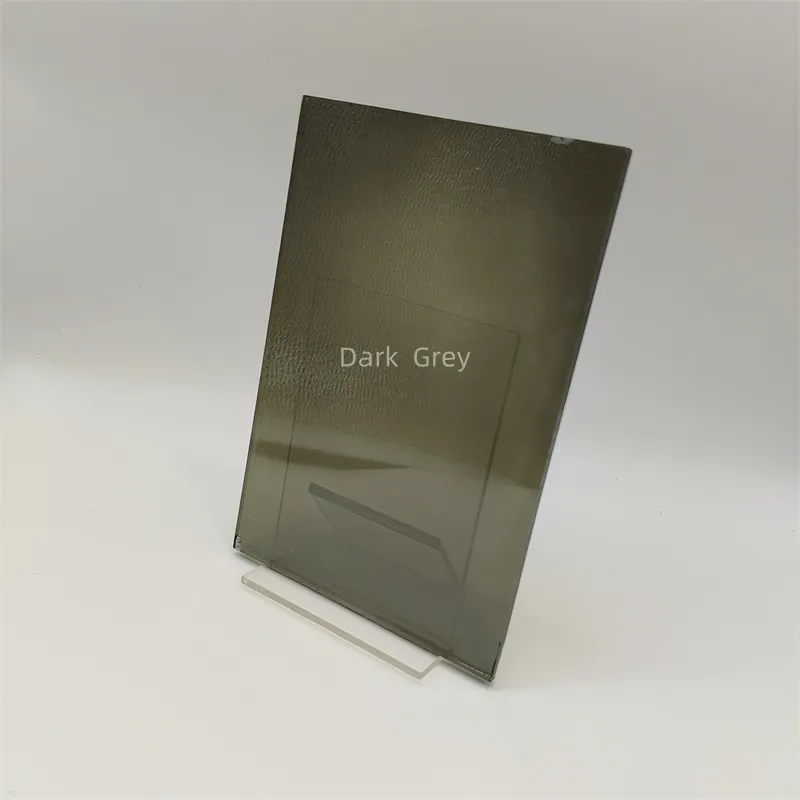

Technical Comparison: Blue vs Black Coated Glass

Source: Product Lab Testing, 2024; Industry ReportBreakdown: Global Coated Glass Market by Use Case (2023, %)

Source: Markets & Research, Glass Facade AssociationYearly Price Index (2017–2024): Coated Glass Price Trend (USD/m²)

Note: Sample is for 6mm blue coated glass, ex-factory China, VAT excluded4. Industry Applications: coated glass uses & Performance Scenarios

Blue coated glass is widely employed in applications that prioritize thermal comfort, UV protection, and aesthetic value. Below are the core industries and the technical rationales for its selection.

- Commercial & Public Architecture: Glass curtain walls, offices, airports - provides daylighting, reduces HVAC loads by up to 30% (confirmed by Facade Journal).

- Residential Facade: Windows, balconies - enhances indoor comfort, shields against UV and glare.

- Industrial Equipment: Control room panels, laboratory partitions - stable color, high resistance to chemical fumes, achieves ASTM E2180 anti-microbial pass level.

- Solar Photovoltaic: Glass front layers for BIPV (Building Integrated Photovoltaics) - supports >90% UV rejection for module durability.

- Transportation: Train, bus, marine windows - anti-fog coating options support SAE J2302 marine safety tests.

Performance & Technical Advantages

- Energy Savings: Reduces solar heat ingress by 38–55% (g-value, 6mm double glazed)–ranks top among all color-coated options (per EN410 tests).

- Surface Hardness & Abrasion Resistance: Sputtered metal-oxide coatings achieve ≥ 6H hardness (ASTM D3363), outperforming basic reflective film glass.

- Color Consistency: Advanced magnetron control technology (PID feedback) achieves ΔE ≤ 1.5 (ISO 11664-4) over large panels, crucial for facade projects.

5. Supplier Comparison: Major Coated Glass Manufacturers (2024)

| Supplier | Country | Main Coated Product | Certifications | MOQ (m²) | Lead Time (days) |

|---|---|---|---|---|---|

| Jointas Glass (China) | China | Blue, Black, Silver Low-E Coated | CE, ISO 12543, SGS | 300 | 12–18 |

| AGC Glass | Belgium/Japan | Sunergy Blue, Stopray, Black Coated | CE, RoHS, Cradle2Cradle | None (distributor based) | 18–28 |

| NSG Pilkington | UK/Japan | Eclipse Advantage Blue, Solar-E Black | CE, ISO 9001, LEED | 500 | 24–32 |

| Saint-Gobain | France | Cool-Lite Blue, Parsol Black | CE, ISO 14001, ASTM C 1172 | 250 | 16–22 |

| Sisecam | Turkey | Thermal Control Blue, Black | CE, EPD, IFT Rosenheim | 225 | 15–20 |

6. Customization & Project Solutions

Coated glass is highly adaptable. Customization ensures that building or industrial needs are met regarding color, solar control, mechanical performance and even logo/printing.

- Color Customization: RAL/NCS code matching, multi-layer coating adjustment (tint ±15%).

- Panel Shape: CNC/robotic cutting for complex geometry (radius ≥ 120 mm; polygonal, round, trapezoid shapes available).

- Coating Stack: Options include dual/tri-oxide, hard/soft coatings, anti-fingerprint, and self-cleaning (hydrophilic) layers.

- Lamination, Tempering: Available for ballistic, impact or high-loading environments, per EN 12600/ISO 12543.

Typical Custom Project Delivery Cycle

| Phase | Timeframe (days) | Key Activities |

|---|---|---|

| Sample Design & Approval | 3–7 | Color matching, sample shipping, client sign-off |

| Mass Production | 7–14 | Substrate cut, coating, temper/laminate as per project |

| Inspection & Packing | 2–3 | QC (coating thickness, color ΔE, visual), packaging per EN12600 |

| Shipping & Documentation | 5–12 | Export docs, delivery or CIF/DDU/EXW shipment |

7. Real-World Application Cases

-

Case 1: Guangzhou High-Tech Park Office Facade

Area: 2800 m² | Spec: 8mm blue coated glass, double-glazed

✓ Result: Lowered cooling load by 31%, yearly electricity cost savings ≈ $9.5/m², achieved LEED Silver. -

Case 2: Dubai Metro Station Platform

Spec: 6mm blue/black coated glass composite, anti-glare finish

✓ Result: Passed ASTM E2190 fog/humidity test, 9+ years without color fading under desert sunlight. -

Case 3: Chemical Processing Plant Control Room

Spec: 10mm blue coating, multi-layer anti-corrosive

✓ Result: Maintained optical clarity, zero coating delamination after 3 years sulfuric/fuming acid exposure. -

Case 4: Bangalore IT Hub-BIPV Integration

Spec: 5mm blue coated glass (front cover, PV panels)

✓ Result: Enable high solar transmittance, modules passed IEC 61215, ISO 9488. -

Case 5: Seoul New Energy-Residential Tower

Spec: 6mm black coated glass (balcony/partition)

✓ Result: Improved privacy and anti-glare, zero maintenance repaint for 7 years.

End-User Testimonials

"Strength & Color Uniformity" “We switched all main east facade panels to blue coated glass from Chinamirrorglass in 2023 and energy bills dropped by 28%. Crucially, the blue shade across 1000+ glass units was visually consistent — critical for our project aesthetics. We recommend for green builds.”

— Project Director, EcoDesign Partners, Singapore

8. FAQ: Professional FAQ on Coated Glass Products

A: Typically, high-clarity float glass (SiO₂ ≥ 72%, Fe₂O₃ ≤ 0.04%) is used to ensure the best optical transmission and color fidelity. All raw glass must comply with EN 572-2 standard.

A: Common thicknesses: 4mm, 5mm, 6mm, 8mm, 10mm, 12mm. Max panel: 3300 × 6000 mm (subject to plant capability). Custom CNC cutting is available for special geometries.

A: Yes, both tempered (toughened) and laminated blue coated glass are offered. Tempered glass is 4–5x stronger than annealed, meeting ANSI Z97.1 and EN 12150.

A: Every batch undergoes wet adhesion testing (ISO 2409), salt mist, humidity, and UV weathering (EN 1096). For industrial/chemical settings, corrosion resistance is tested per ASTM G85.

A: Curtain wall systems must meet EN 13830 (EU) or ASTM E1300 (USA), including wind load, impact, and fire performance criteria. Proper edge protection of the coating layer is crucial.

A: Blue coated glass price (6mm, ex-factory China): $8.5–$9.5/m²; black coated: $10.0–$11.0/m² (2024). Black offers stronger absorption (privacy, UV cut), blue favors daylighting/comfort.

A: Jointas and major suppliers provide a 10-year delamination/discoloration warranty when installed per technical datasheet. Tech support includes on-site or remote QC, replacement, troubleshooting.

9. Why Trust Chinamirrorglass for Blue Coated Glass?

- Certified ISO 9001/12543, CE, SGS, CNAS testing for each order;

- Over 17 Years export experience, 35+ countries, key partner to Fortune 500 construction contractors;

- Custom Engineering for color, size, performance; digital project file & technical consultation for all jobs.

- Discover Blue Coated Glass Options

References & Further Reading

- Markets & Markets, "Coated Glass Market by Type, Application – Global Forecast to 2030", https://www.marketsandmarkets.com/Market-Reports/coated-glass-market-261159657.html

- Facade Journal, "Solar Performance of Color Coated Glass", https://facadejournal.com/solar-performance-color-glass

- Structurae, "Technical Specifications: Glass for Buildings", https://structurae.net/en/materials/glass

- Glass International, "Advances in Magnetron Sputtering Coating Tech", https://www.glass-international.com

- EN Standards, "Flat Glass: Basic and Special Products", EN 572-2

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS