Nov . 17, 2025 17:08 Back to list

What Is Dichroic Glass?

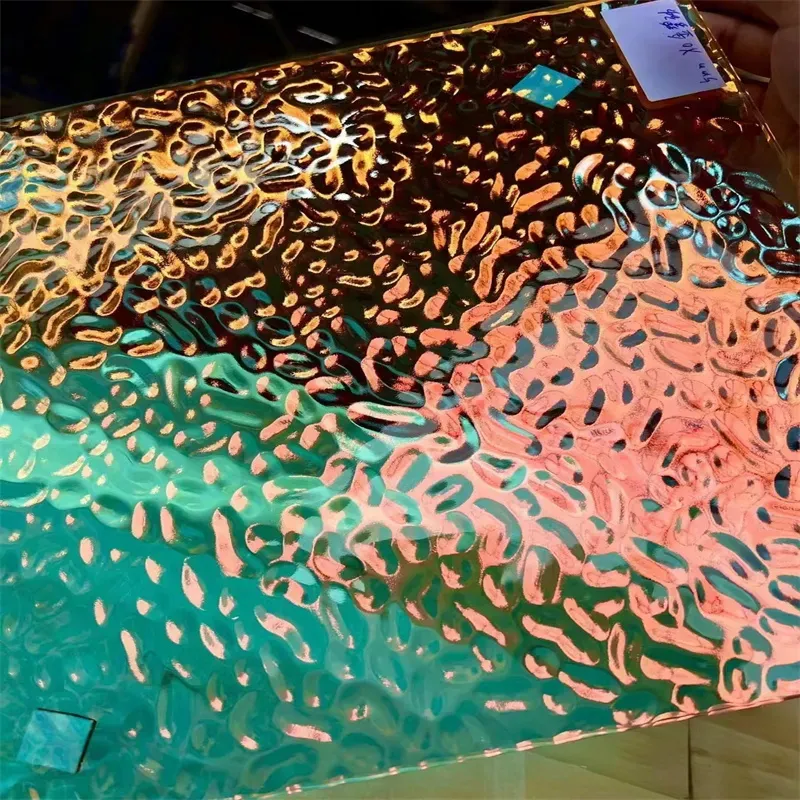

Dichroic glass is one of the most captivating and widely used specialty glasses in today’s art, jewelry, and architectural design industries. Known for its vibrant color-shifting appearance, it stands out as a material that blends advanced technology with artistic expression. But what exactly is dichroic glass, and why has it become so popular? This article breaks down its meaning, history, production process, applications, and tips on choosing high-quality dichroic glass.

1. Definition: What Is Dichroic Glass?

The term dichroic comes from the Greek words di (two) and chroma (color), meaning “two-colored.”

In simple terms, dichroic glass is a material that displays two or more different colors depending on the angle of light or the viewer’s perspective.

This color-shifting effect happens because the surface of the glass is coated with multiple micro-thin layers of metallic oxides. When light reflects off these layers, some wavelengths are reflected while others pass through, creating shimmering colors that appear to change constantly.

Dichroic glass is not painted or dyed — the color is produced by optical physics, not pigment. As a result, the colors are extremely vibrant, fade-resistant, and dynamic.

2. The History of Dichroic Glass

Although dichroic glass may look ultra-modern, its roots go back centuries.

The most famous early example is the Lycurgus Cup, a 4th-century Roman artifact that shifts between green and red depending on lighting.

However, modern dichroic glass as we know it was developed in the 1960s by NASA.

It was created for:

Thermal protection

Radiation shielding

Optical filters

Spacecraft instrumentation

The same technology used to protect astronauts eventually found its way into the art and design industries, inspiring a new era of decorative glasswork.

3. How Dichroic Glass Is Made: The Science Behind It

Dichroic glass is produced using a high-tech vacuum deposition process known as thin-film coating.

Step-by-step:

A base sheet of glass is placed inside an industrial vacuum chamber.

Metallic oxides — such as titanium, chromium, silicon, magnesium, or aluminum — are vaporized using an electron beam.

These vapors bond to the glass in extremely thin layers, sometimes 30 to 50 layers, each only a few atoms thick.

The coated glass is removed and often fused again in a kiln for stability and durability.

Because each layer interacts differently with light, the result is a material that visibly shifts colors when tilted or moved.

Why it is special:

-

The coating is permanent and will not peel.

-

It resists fading, even in sunlight.

-

Every sheet has a slightly unique pattern and color reaction.

This makes dichroic glass both scientifically fascinating and artistically valuable.

4. Types of Dichroic Glass

There are two main categories:

1. Reflective Dichroic Glass

Shows the strongest color when light reflects off its surface.

Used often in jewelry and decorative objects.

2. Transmissive Dichroic Glass

Shows its primary color when light passes through the glass.

Popular in windows, lampwork, and architectural elements.

Many artists use both types to create layered, multidimensional effects.

5. What Is Dichroic Glass Used For?

Thanks to its eye-catching appearance and durability, dichroic glass is used in many fields:

Jewelry Making

The most common application. Dichroic glass pendants, rings, earrings, and beads are valued for their vibrant, gemstone-like appearance. Because each piece is unique, it appeals to art jewelry markets.

Decorative Art

Glass artists use dichroic sheets in:

-

Sculptures

-

Mosaic artwork

-

Glass panels

-

Wall decor

-

Fused glass platters or bowls

The color play enhances visual depth and modern style.

Stained Glass Windows

Dichroic elements are added to contemporary stained-glass installations for a dynamic effect when sunlight changes throughout the day.

Architecture & Interior Design

Dichroic coatings are used in:

-

Building facades

-

Art installations

-

Luxury interior partitions

-

Lighting fixtures

-

Hotel lobbies and modern commercial spaces

Large-scale dichroic glass installations often become iconic features of buildings.

Optics & Technology

Because of its scientific origin, dichroic glass is still used in:

-

Camera lenses

-

Laser optics

-

Filters

-

Sensors

-

Scientific instruments

Its ability to filter wavelengths precisely makes it valuable for research and engineering.

6. Why Artists and Designers Love Dichroic Glass

1. Brilliant, Color-Shifting Effects

Few materials offer the same spectrum of iridescent colors.

2. Lightweight Alternative to Gems

Dichroic jewelry can mimic the sparkle of opals or gemstones at a lower cost and weight.

3. High Durability

The thin-film coating is extremely tough and long-lasting.

4. Unlimited Creative Possibilities

Cutting, fusing, engraving, and layering produce countless design variations.

5. One-of-a-Kind Results

Even with the same sheet of glass, no two pieces look identical.

7. How to Identify High-Quality Dichroic Glass

When choosing dichroic glass, consider these factors:

1. Evenness of Coating

Look for smooth, consistent color transitions without patchy areas.

2. Purity of Base Glass

Clear or black glass bases are common; impurities can distort color.

3. Kiln-Fired Stability

Properly fused dichroic glass resists cracking and withstands temperature stress.

4. Thickness and Durability

Thicker or multi-layered pieces create stronger color reflections.

5. Manufacturer Reputation

High-end suppliers use reliable deposition systems, producing brighter and more stable colors.

8. Is Dichroic Glass Expensive?

Dichroic glass is generally more expensive than regular colored glass, mainly due to its complex manufacturing process.

Prices depend on:

-

Number of coating layers

-

Sheet size

-

Base glass type

-

Brand and production quality

However, for the visual impact it provides, many artists and jewelers consider it well worth the cost.

9. Why Dichroic Glass Stands Out

Dichroic glass is a rare combination of science, technology, and artistry.

It captures light in a way few materials can, shifting colors with every angle and movement. Whether used in jewelry, art installations, architecture, or scientific equipment, dichroic glass provides a unique and unforgettable visual experience.

Its durability, versatility, and dazzling color effects make it a favorite among artists, designers, and collectors around the world.

Related PRODUCTS