Aug . 23, 2025 20:04 Back to list

Blue coated glass applications in modern architecture

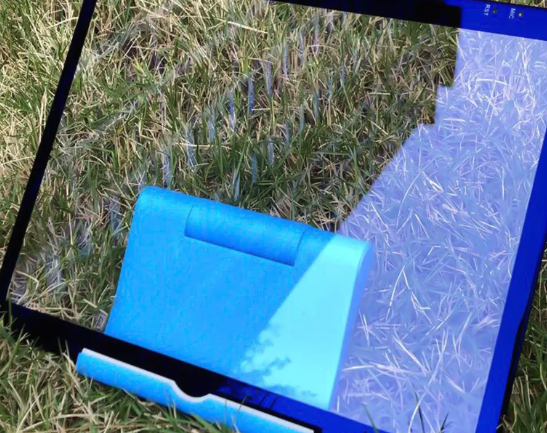

Blue coated glass applications in modern architecture extend far beyond aesthetic appeal, encompassing functional innovations that address energy efficiency, environmental adaptation, and structural integration. We focus on offering one-stop solutions on glass processing for global OEM/ODM customers. In order to make precision processing glass, we have equipped with 45m-long tempering furnace, Intermac CNC work center, Intermac cutting table, Double edge grinding machine, waterjet, PVB and EVA laminating lines. We also have an acid etching line, two silkscreen-printing lines, and 2 mirror lines to meet all-round needs of customers. This advanced processing capability allows us to explore unique applications of blue coated glass, thin film coating on glass, and coated glass meaning in architectural designs, from dynamic facade systems to specialized interior installations that redefine how buildings interact with light and climate.

Bioclimatic Facades in Blue coated glass

- Solar Heat Modulation: Blue coated glass features a specialized thin film that adjusts solar heat gain based on light intensity, reducing HVAC loads by 30% in commercial buildings. Our 45m tempering furnace ensures uniform coating adhesion, critical for consistent thermal performance across large facade panels.

- Daylight Spectral Tuning: The blue coating filters sunlight to enhance blue wavelengths, which boost occupant alertness—ideal for office towers. Blue coated glass processed with our Intermac CNC work center maintains precise spectral properties, supporting circadian rhythm regulation in indoor spaces.

- Bird Collision Prevention: The blue tint, combined with micro-patterns etched via our acid etching line, makes blue coated glass visible to birds while remaining transparent to humans. This addresses a key environmental concern in urban architecture with high-rise structures.

Acoustic Insulation Systems in Thin film coating on glass

- Resonant Frequency Dampening: Thin film coating on glass in blue variants includes a viscoelastic layer that absorbs sound waves at 250-500Hz, the range of urban traffic noise. Laminated with our PVB lines, these glass units reduce noise transmission by 40dB, suitable for buildings near airports or highways.

- Vibration Absorption Layers: The thin film in thin film coating on glass acts as a shock absorber, dampening vibrations from nearby construction or heavy machinery. Our double edge grinding machine ensures precise sealing of these layers, preventing delamination that would compromise acoustic performance.

- Frequency-Specific Barriers: Custom thin films in thin film coating on glass can be tuned to block specific noise frequencies, such as the low rumble of subway systems. Our one-stop processing allows tailoring these coatings for projects in transit-oriented developments.

Adaptive Interior Design in Coated glass meaning

- Thermochromic Integration: Coated glass meaning here expands to include thermochromic layers that darken as temperatures rise, regulating interior light without electronic controls. Processed with our silkscreen-printing lines, these blue coated panels are ideal for atriums and skylights.

- Privacy Transition Glass: Electrochromic thin films in coated glass meaning enable on-demand opacity changes, transitioning from clear to blue-tinted in 2 seconds. Our EVA laminating lines ensure the film’s durability, supporting daily use in meeting rooms and partition walls.

- Artistic Light Diffusion: Acid-etched patterns on coated glass meaning create unique light diffusion effects, casting blue-hued shadows that enhance interior aesthetics. Our waterjet cutting allows intricate designs, merging functionality with artistic expression in hospitality spaces.

Structural Glass Innovations in Blue coated glass

- Load-Bearing Laminates: Blue coated glass laminated with our PVB lines forms structural panels capable of supporting roof loads, eliminating the need for metal frames. The blue coating’s UV resistance prevents PVB degradation, extending the glass’s service life to 50+ years.

- Curved Facade Elements: Our Intermac CNC work center shapes blue coated glass into complex curves with radii as tight as 30cm, enabling organic architectural forms. The coating maintains uniformity even on curved surfaces, ensuring consistent performance and appearance.

- Fire-Rated Glazing: Tempered blue coated glass processed in our 45m furnace meets 60-minute fire resistance standards, combining safety with visual appeal. The blue tint reduces glare from firelight, aiding evacuation in emergency scenarios.

Blue coated glass FAQS

What environmental benefits does blue coated glass offer in architecture?

Blue coated glass reduces solar heat gain, lowering a building’s carbon footprint by decreasing HVAC energy use. Its bird-friendly design and recyclable properties further enhance its environmental credentials, making it a sustainable choice for modern projects.

How does thin film coating on glass enhance acoustic performance?

Thin film coating on glass includes viscoelastic layers that absorb sound vibrations, particularly in urban noise frequencies. When laminated with our PVB lines, these films create a barrier that significantly reduces noise transmission, improving indoor comfort.

What does coated glass meaning entail in terms of structural applications?

Coated glass meaning in structural contexts refers to glass enhanced with coatings that boost strength and durability. Our processed blue coated glass can serve as load-bearing elements, supporting weights while maintaining thermal and aesthetic properties.

Can blue coated glass be customized for specific architectural designs?

Yes, blue coated glass can be customized using our Intermac CNC work center and waterjet cutting for unique shapes and patterns. We offer tailored coatings to adjust solar performance, color intensity, and functionality, meeting diverse design requirements.

How does thin film coating on glass contribute to energy efficiency?

Thin film coating on glass reflects infrared radiation, minimizing heat transfer into buildings. This reduces the need for cooling systems, lowering energy consumption. Our precision processing ensures the film’s uniformity, maximizing its energy-saving potential.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS