Oct . 13, 2025 14:25 Back to list

Coated Glass | Low-E, Solar Control, Custom Cuts & Fast Lead

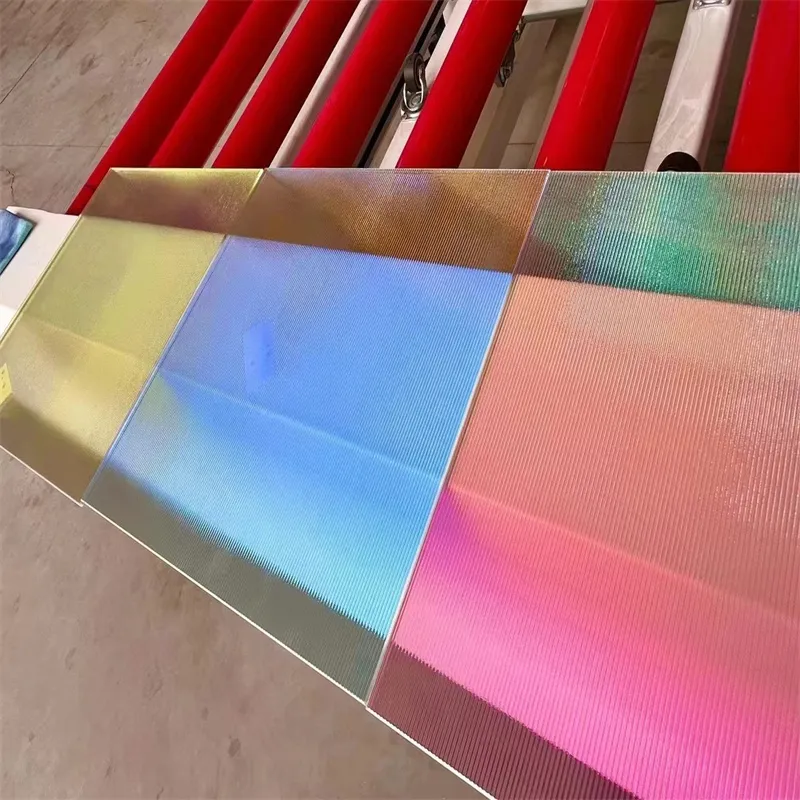

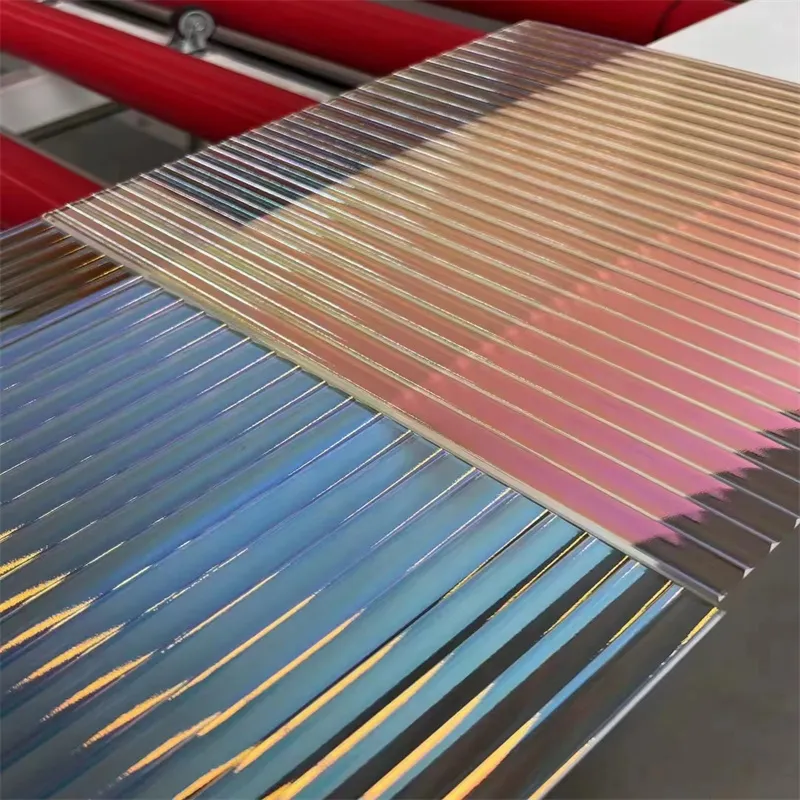

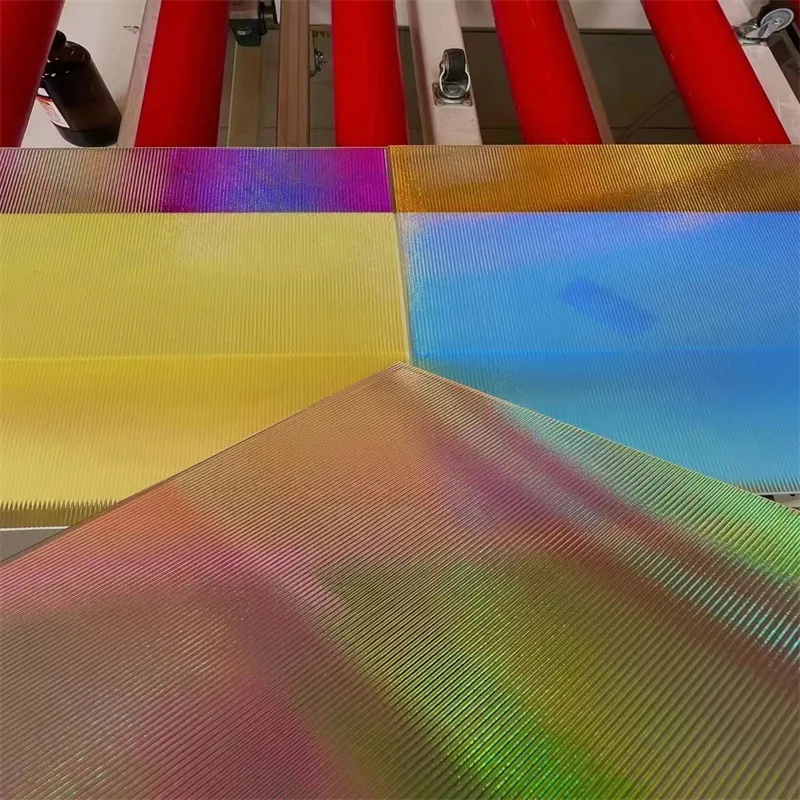

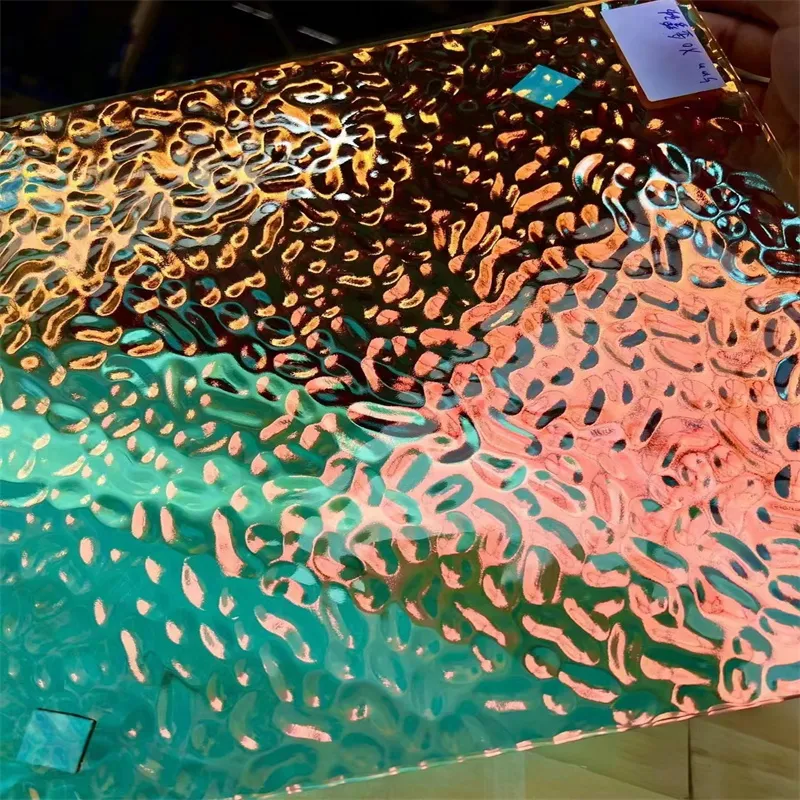

Dichroic Glass: the color-shifting coated glass architects actually ask for

If you’ve ever watched a façade turn from teal to amber as the sun moves, that’s probably dichroic at work. It’s a multi-layer interference stack deposited by magnetron sputtering—precise, thin, elegant. And, to be honest, a little addictive for designers. Our source here is the Hebei plant in Shahe City, Xingtai (North Second Row, East Side of Dadong Logistics, Economic Development Zone)—a region that’s become a quiet powerhouse for specialty optics.

What’s trending now

Two currents define demand: net‑zero buildings (more spectral control, less HVAC pain) and Instagram-era retail (bold, photogenic interiors). In fact, many customers say they pick dichroic specifically for “movement”—that subtle color flip as your viewpoint shifts. On the supply side, stacks are getting tougher; abrasion resistance and edge-stability are way better than they were five years ago.

Quick technicals (real-world values)

| Parameter | Typical Range (≈, may vary) |

|---|---|

| Substrate | Low‑iron float, 3–10 mm |

| Visible Light Transmission (Tv) | 8–45% (EN 410 / ISO 9050) |

| Visible Reflectance (Rv, front) | 15–60% |

| Solar Factor g | 0.25–0.55 |

| Color shift angle | ≈20–45° incidence |

| Coating method | Magnetron sputtering, multi‑oxide stack |

| Durability | EN 1096-2 tests passed (abrasion, condensation); laminate/IGU recommended outdoors |

| Service life | 10–20 years in IGU/laminate, proper edge sealing |

| Certifications | CE, RoHS, REACH, CCC (project-dependent) |

Process flow, briefly

- Material prep: low‑iron float cut to size, edges seamed.

- Wash: deionized water, brush-wash, Class 1000 line entry.

- Sputter coat: alternating metal oxides (TiO2/SiO2/ZrO2… depends); thickness control ±1–2 nm.

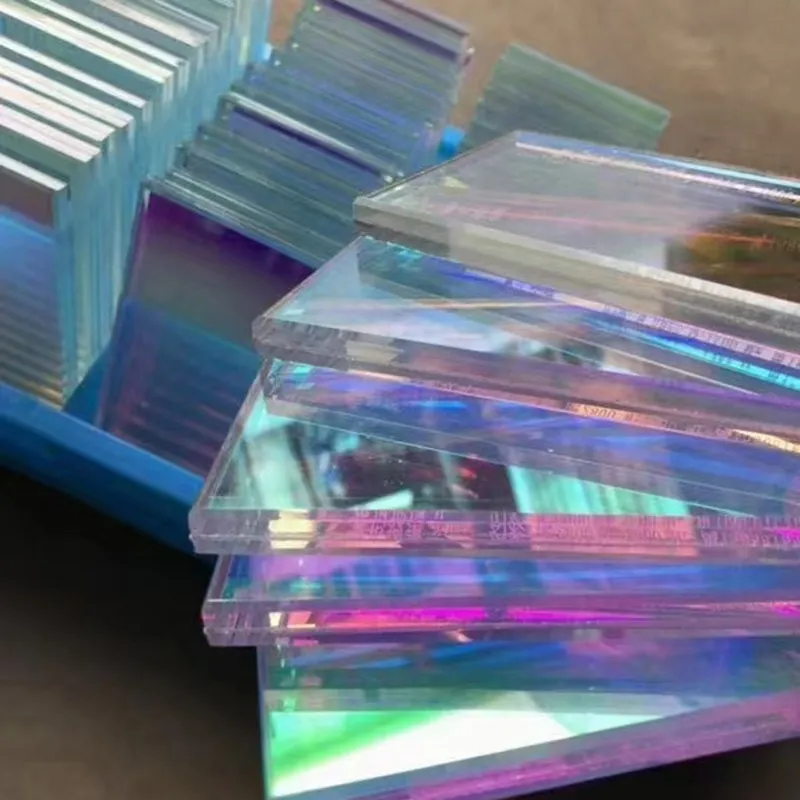

- Optional heat treatment: temper/heat-strengthen post‑coat as allowed by stack design.

- Lamination/IGU: PVB/EVA interlayer or double glazing to protect the coating and extend life.

- Testing: EN 1096-2 durability, ISO 9050/EN 410 optics, ISO 9227 salt‑spray (edges), boil test for laminates.

In shop talk, that means a stable, repeatable interference stack. And yes, coated glass hates bad edgework—seal it well.

Where it shines

Applications: retail backdrops, hospitality lobbies, feature ceilings, balustrades, art and exhibit cases, skylights (in IGU), lighting diffusers, even brand signage. Advantages: striking visual identity, selective spectral control, and—surprisingly—useful glare management when specified with care. Some installers note it also hides clutter nicely because of reflective masking.

Vendor snapshot (what buyers compare)

| Vendor | Stack Tech | Lead Time | Certs | Notes |

|---|---|---|---|---|

| China Mirror Glass (Hebei) | Precision sputter, nm-level control | 2–4 weeks | CE/RoHS/REACH/CCC | Custom colors, large sheets up to ≈2440×3660 mm |

| Importer A | Standard stack | 5–8 weeks | CE | Limited thickness options |

| Architectural Brand B | Premium stack, tight ΔE | 4–6 weeks | CE/EPD | Higher price; strong documentation |

Customization tips

Pick substrate (3, 6, 8, 10 mm), choose color family (cool, warm, neutral flip), decide protection (laminate vs. IGU), and lock tolerances. For public areas, I’d specify edge seals and request EN 1096-2 abrasion data plus a salt-spray result for peace of mind. Also, confirm cleaning guidance—coated glass prefers non‑abrasive, pH‑neutral agents.

Two quick case notes

Retail flagstore, Dubai: 6 mm dichroic laminated to 6 mm clear, Rv ≈38%, Tv ≈22%. Outcome: daytime glare cut and “color-shift moment” for social posts. Feedback: “Footfall uptick after refit; maintenance zero issues in 10 months.”

University atrium, EU: IGU with dichroic outer lite (inboard coat) + low‑e inner. g‑value ≈0.35. Acoustic PVB. Result: lower cooling load and a softly animated light field. Facilities team said cleaning was “no harder than mirrors,” which is saying something.

Bottom line

Dichroic is artful yet technical. Specify by numbers (EN 410/ISO 9050 optics, EN 1096 durability), protect it (laminate or IGU), and you’ll get years of color play. It seems that’s what keeps designers coming back to coated glass that doesn’t behave like ordinary glass at all.

Authoritative citations

- EN 1096-2: Glass in building — Coated glass — Requirements and test methods.

- EN 410: Glass in building — Determination of luminous and solar characteristics.

- ISO 9050: Glass in building — Determination of light transmittance, solar direct transmittance, total solar energy transmittance.

- ASTM C1376: Standard Specification for Pyrolytic and Vacuum Deposition Coatings on Flat Glass.

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS