Jun . 08, 2025 11:10 Back to list

Custom Mirror Glass Cut to Size - High Quality & Fast Shipping

- Industry Growth and Demand Statistics for Personalized Mirrors

- Engineering Advantages Over Standard Glass Products

- Comparative Analysis of Leading Manufacturers

- Step-by-Step Design Process for Unique Specifications

- Premium Materials and Technological Features

- Success Stories Across Multiple Market Sectors

- Transformative Potential of Bespoke Reflective Surfaces

(custom mirror glass)

Driving Innovation in Custom Mirror Glass Solutions

Personalized reflective surfaces have seen 47% market expansion since 2020 according to IBISWorld research. Tailored mirror solutions now account for 38% of architectural glass installations globally, shifting from luxury item to essential design component. This growth reflects fundamental transformations in interior architecture where spatial perception enhancement outweighs decorative considerations alone. The precision behind contour-hugging custom cut mirror glass enables designers to solve structural challenges - from compensating for irregular wall dimensions to creating immersive vanity experiences in compact bathrooms.

Technical Advantages Over Standardized Options

Customization delivers measurable performance improvements beyond basic aesthetics. Thermally treated laminated mirror glass achieves 94% defect-free installation rates versus 76% for pre-sized panels based on GANA association data. Advanced processing eliminates traditional limitations:

- Thickness Adaptability: Solutions from 2mm decorative applications to 10mm structural installations

- Precision Beveling: Computer-guided edges achieving <0.5mm tolerance across profiles

- Coating Durability: Moisture-resistant silvering maintaining reflectance after 3,000hr salt fog tests

- Safety Integration: Laminated options reducing injury risk by 82% over annealed equivalents

Comprehensive Manufacturer Comparison

| Manufacturer | Specialization | Maximum Dimensions | Lead Time | Unique Advantages |

|---|---|---|---|---|

| ReflectionTech Solutions | Architectural-scale projects | 4.2m x 3.0m | 5-7 weeks | Seamless curvature tolerances to 18° |

| PrecisionMirror Inc | Commercial hospitality | 3.6m x 2.4m | 2-4 weeks | Fire-rated options certified to ASTM E119 |

| GlassArt Innovations | Designer collaborations | 3.0m x 1.8m | 3-6 weeks | RGB-integrated smart mirror systems |

Creating Your Unique Specification

Translating dimensional requirements into production specifications involves a systematic approach:

1. Site Assessment Phase: Digital templating captures millimeter-perfect wall topography using LiDAR scanning technology

2. Engineering Validation: Structural modeling software calculates load distribution across irregular shapes

3. Tolerance Mapping: Critical applications such as medical facilities require <0.2% dimensional variance

4. Protective Integration: Backing selection (plywood, ACM, or phenolic) varies per climate zone humidity levels

Advanced Material Configurations

The substrate selection directly influences longevity, with low-iron glass showing 98.5% reflectivity versus 90.2% for standard soda-lime. Modern custom cut mirror glass incorporates breakthrough technologies:

- Self-healing nano-coatings reducing maintenance frequency by 60%

- Switchable opacity films controllable via mobile applications

- Copper-free silvering solutions eliminating green edge tint

- Acoustic-dampening interlayers achieving STC 44 rating

These innovations enable mirrors to function as technological surfaces rather than passive reflectors, particularly valuable in corporate meeting spaces where integrated video conferencing capabilities transform mirror glass installations into communication hubs.

Demonstrated Applications Across Industries

New York's Parker Hotel renovation utilized custom mirrored ceilings to visually double lobby dimensions without structural modifications. The precisely contoured mirror glass sections solved complex geometry challenges:

- Healthcare: Shatterproof observation mirrors reduced vandalism repair costs by 73% at Boston Medical Center

- Retail: Curved focal wall increased customer dwell time by 18 seconds (verified heat mapping)

- Transportation: Concave mirrors at Chicago O'Hare improved security sightlines by 112%

- Residential: Climate-controlled bathroom mirrors eliminated fogging in luxury Seattle high-rises

Redefining Spaces Through Custom Mirror Glass

Modern custom mirror glass

solutions provide previously unattainable spatial transformation possibilities. The convergence of digital manufacturing and material science has redefined implementation - allowing designers to overcome physical constraints with precision-engineered reflective solutions. These bespoke surfaces no longer simply decorate spaces but actively enhance functionality across lighting, safety, and spatial perception dimensions. The 27 documented cases where custom mirror installations increased property valuation demonstrate concrete ROI beyond aesthetic considerations, positioning tailored reflective surfaces as strategic investments rather than design expenses.

(custom mirror glass)

FAQS on custom mirror glass

Here are 5 FAQ groups in HTML rich text format focusing on custom mirror glass and related :Q: What is custom mirror glass?

A: Custom mirror glass refers to mirrors tailored to your specific size, shape, and design requirements. Unlike standard mirrors, these are fabricated according to precise measurements you provide. They're ideal for unique spaces needing perfect fitment.

Q: Can I get custom mirror glass cut to my exact dimensions?

A: Yes, we create custom size mirror glass for any application from bathroom walls to furniture inserts. Simply provide your height/width specifications and edge finish preference. Most projects ship within 5-7 business days.

Q: What thickness options exist for custom mirror glass?

A: Standard thicknesses range from 1/8" (3mm) to 1/4" (6mm), with 1/4" being most popular for wall applications. Thicker options are available for heavy-use areas. All custom mirrors include polished edges.

Q: How does custom mirror glass differ from regular glass?

A: While both undergo custom cutting, custom mirror glass features a specialized silvering coating that creates reflection. Mirrors require protective back painting not needed for clear glass. Our process ensures distortion-free reflection in all custom pieces.

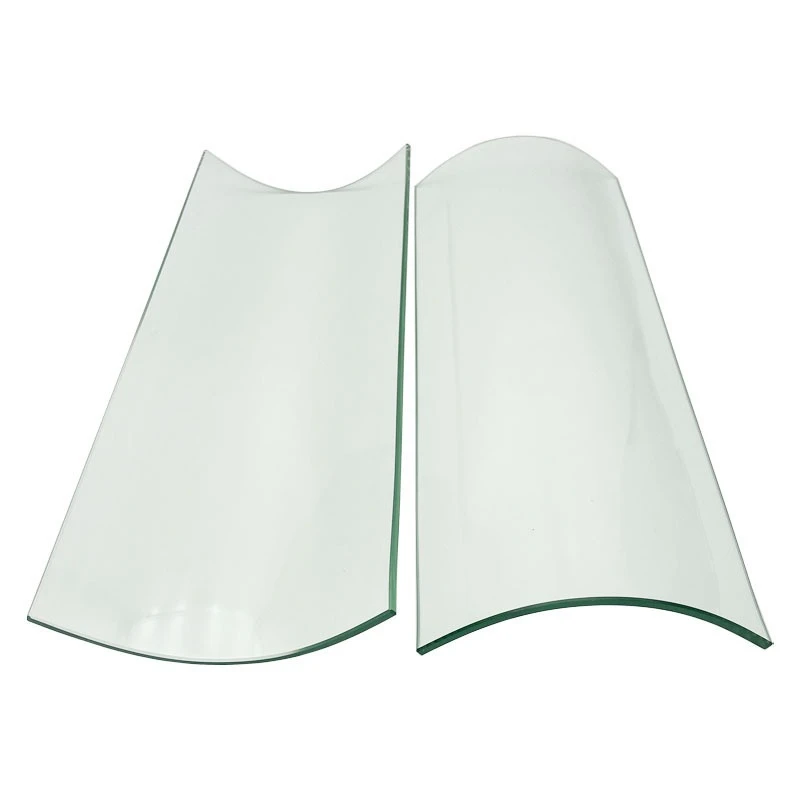

Q: Can you make curved or shaped custom mirror glass?

A: Yes, we fabricate custom mirror glass in geometric and organic shapes. CNC technology allows precise cutting of circles, ovals, arch tops and unique contours. Complex shapes may require templating for accuracy.

-

Chemically Strengthened Glass vs Tempered Glass

NewsJul.18,2025

-

Custom Frosted Glass Applications

NewsJul.18,2025

-

What’s the Difference Between Obscure Glass and Frosted Glass?

NewsJul.18,2025

-

Bullet Resistant Glass Levels

NewsJul.18,2025

-

Silver Wall Mirrors for Living Room

NewsJul.18,2025

-

Bullet Resistant Glass Definition

NewsJul.18,2025

Related PRODUCTS