Aug . 18, 2025 03:20 Back to list

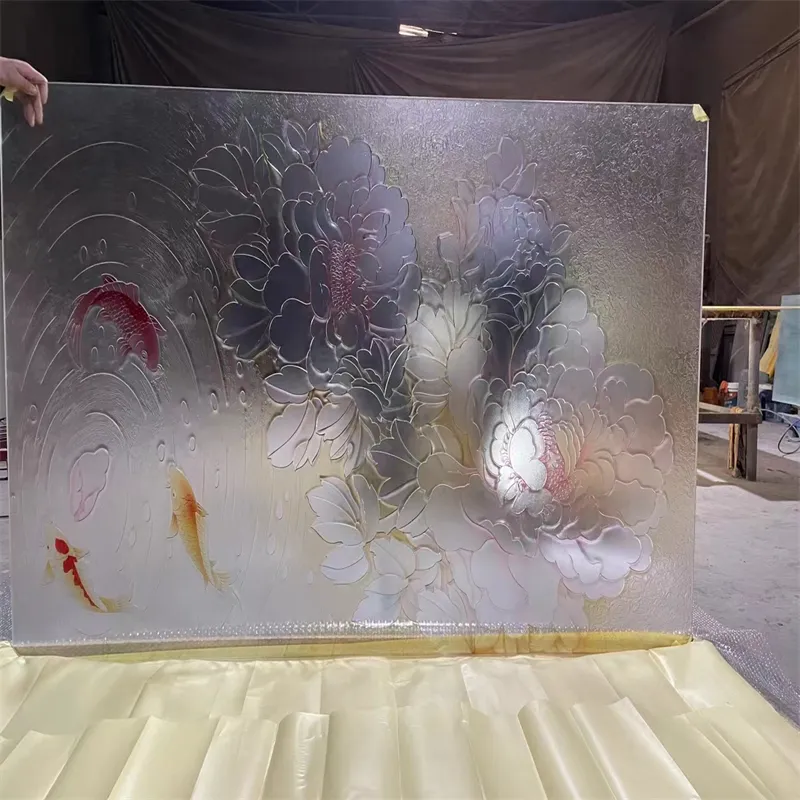

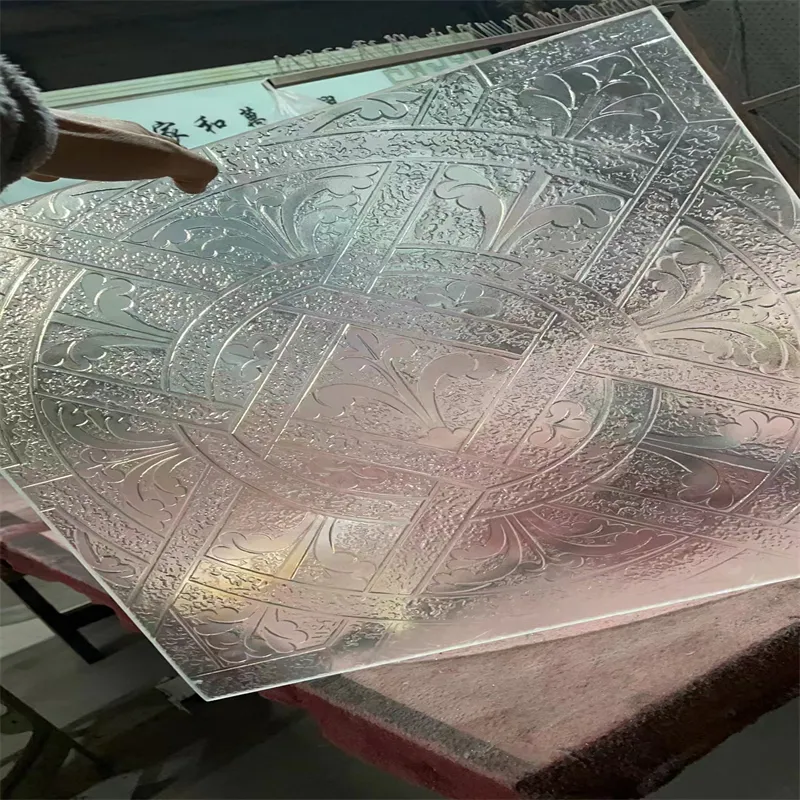

Custom Satin Sandblasted Glass Panels & Designs

In the rapidly evolving landscape of architectural and interior design, satin sandblasted glass stands as a paramount material offering an unparalleled blend of aesthetic appeal and functional privacy. This sophisticated glass variant, celebrated for its subtle translucency and velvety finish, is engineered to diffuse light beautifully while obscuring direct visibility, making it an ideal choice for a myriad of applications where both natural light and personal space are highly valued. Our commitment at [Your Company Name, implied by product URL] lies in leveraging cutting-edge technology and rigorous quality control to produce sandblasted glass solutions that meet the demanding specifications of B2B clients across diverse industries. From enhancing the visual comfort in commercial offices to providing elegant privacy in residential settings, the unique properties of sandblasted glass position it as a superior alternative to traditional transparent or heavily obscured glass types. Its ability to transform ordinary spaces into sophisticated environments, coupled with its inherent durability and ease of maintenance, underscores its growing prominence in modern construction and design paradigms. We delve into the intricate manufacturing processes, technical specifications, and expansive application versatility that define this essential material, aiming to provide a comprehensive resource for industry professionals seeking to understand and integrate premium glass solutions into their projects.

The Art and Science of Satin Sandblasted Glass Production

The creation of satin sandblasted glass involves a meticulous process that begins with high-quality float glass substrates, renowned for their optical clarity and uniform thickness, ranging typically from 3mm to 19mm. The foundational manufacturing technique employs abrasive blasting, where a high-velocity stream of abrasive particles—such as silica sand, aluminum oxide, or carborundum—is directed at the glass surface. The selection of abrasive type, particle size, air pressure (typically ranging from 60-120 PSI), and nozzle distance critically influences the final "satin" finish, which is characterized by a microscopic roughening of the surface that diffuses light rather than blocking it entirely. This controlled erosion creates a frosted, matte appearance that minimizes glare and provides privacy while allowing significant light transmission (often between 70-85%). For intricate designs or custom patterns, advanced masking techniques using vinyl stencils or photo-resist films are employed before the blasting process, ensuring precise delineation of clear and frosted areas, creating elegant custom sandblasted glass options. Post-blasting, the glass undergoes a thorough cleaning process to remove residual abrasive particles and prepare it for further processing like tempering or lamination, which enhance its safety and structural integrity.

Quality control is paramount throughout the manufacturing cycle. Each batch of sandblasted glass panels is subjected to rigorous inspection protocols, including surface uniformity checks to ensure consistent hazing and light diffusion, thickness measurements to meet precise dimensional requirements, and optical clarity tests to verify light transmission and glare reduction properties. Our processes adhere strictly to international standards such as ISO 9001 for quality management systems, ANSI Z97.1 for safety glazing materials (when tempered or laminated), and ASTM C1048 for flat glass, ensuring superior product performance and reliability. The inherent durability of this glass type means an exceptional service life, often exceeding several decades with appropriate maintenance, making it a cost-effective long-term investment. Its resistance to scratching, compared to acid-etched alternatives, further contributes to its longevity. While sandblasted glass is widely utilized across architectural, interior design, and furniture sectors, its properties also lend themselves to more specialized applications in sectors such as healthcare for privacy screens, retail for display elements, and even marine environments where diffused light and robustness are critical. This robust material excels in scenarios demanding energy efficiency through optimized light diffusion, reduced reliance on artificial lighting, and inherent resistance to corrosion or degradation from common environmental factors.

Industry Trends and Technical Parameters Defining Modern Glass Solutions

The market for specialized glass, particularly satin sandblasted glass, is experiencing robust growth driven by increasing demand for privacy solutions that do not compromise on natural light, alongside a surging interest in minimalist design aesthetics. Industry reports project the global architectural glass market to reach approximately USD 120 billion by 2027, with decorative and functional glass segments, including sandblasted varieties, constituting a significant and growing share. Key trends include the integration of decorative glass into smart building technologies, a heightened focus on sustainable manufacturing practices that minimize environmental impact, and the adoption of advanced digital sandblasting techniques for intricate and repeatable sandblasted glass design. Architects and designers are increasingly specifying sandblasted glass for its versatility in creating diffused light environments, which contributes to occupant comfort and reduces the need for artificial lighting, aligning with green building initiatives. Furthermore, the ability to combine sandblasting with other glass treatments, such as low-emissivity coatings or laminations for enhanced acoustic performance, further broadens its applicability. This strategic adaptation ensures that sandblasted glass remains at the forefront of innovative architectural solutions, addressing both functional demands and contemporary design sensibilities while contributing to energy efficiency in modern structures.

Understanding the technical parameters of satin sandblasted glass is crucial for specifying the correct product for any application. These parameters dictate performance, safety, and suitability for various environments. For instance, the degree of frosting can be precisely controlled to achieve desired light diffusion and privacy levels, measured by haze percentage. Thickness availability ranges from 3mm to 19mm, catering to diverse structural and aesthetic requirements, from delicate cabinet inserts to robust shower enclosures and facade elements. The maximum size of panels can be quite substantial, reaching up to 3300mm x 12000mm in some production facilities, allowing for seamless, large-scale installations. Surface roughness, quantified by Ra values (typically in micrometers), defines the tactile feel and visual effect of the satin finish. Compliance with international standards is non-negotiable; our products meet certifications like ISO 9001 for quality management, CE marking for European markets, and specific national standards like AS/NZS 2208 for safety glazing in Australia and New Zealand. Abrasion resistance, though not as high as tempered clear glass, is significantly improved over chemically etched glass, contributing to its longevity in high-traffic areas. Thermal shock resistance ensures the glass can withstand temperature fluctuations without cracking, a critical factor for exterior applications or areas exposed to heating/cooling cycles. The table below provides a concise overview of typical specifications.

Typical Technical Specifications for Sandblasted Glass

Diverse Applications and Unrivaled Advantages

The versatility of satin sandblasted glass extends across a vast spectrum of applications, making it an indispensable material in both residential and commercial projects. In commercial settings, it is extensively used for office partitions, creating private yet light-filled workspaces that foster collaboration without sacrificing individual focus. Conference rooms benefit from its ability to offer discreet privacy during sensitive discussions, while retail storefronts can utilize sandblasted elements for branding or to create visually appealing displays that diffuse harsh external light. In hospitality, luxury hotels and restaurants incorporate sandblasted glass design for shower enclosures, decorative wall panels, and elegant balustrades, contributing to a sophisticated ambiance. Residential applications include bathroom screens, shower doors, cabinet inserts, and interior doors, where it elegantly balances light and privacy. Beyond standard installations, specialized applications range from artistic glass features in public spaces, backlit signage that diffuses illumination evenly, to specific components in medical facilities where privacy is paramount, such as examination room dividers. Its adaptability allows architects and designers to unleash creative freedom, incorporating it into virtually any interior or exterior glass requirement where diffused light and visual separation are desired.

The technical advantages of satin sandblasted glass are numerous and directly contribute to its widespread adoption. Foremost is its exceptional ability to provide privacy without blocking natural light, a critical factor for human well-being and energy efficiency. Unlike opaque materials, sandblasted glass diffuses incoming light, reducing glare and creating a softer, more ambient illumination. This anti-glare property is particularly beneficial in environments with strong sunlight or artificial light sources. From an aesthetic perspective, the frosted finish offers a sleek, modern look that complements contemporary design schemes, allowing for intricate sandblasted glass design patterns and bespoke artistic elements, including corporate logos or abstract motifs. The surface is also more resistant to fingerprints and smudges compared to clear glass, making it relatively easy to clean and maintain its pristine appearance. When tempered or laminated, it transforms into a safety glass, significantly reducing the risk of injury from breakage. Its versatility extends to its compatibility with various framing systems and its suitability for integration into double glazing units for enhanced thermal and acoustic performance. Our clients frequently report increased user comfort and satisfaction due to the unique balance of light and privacy achieved through our sandblasted glass solutions.

Customization and Manufacturer Considerations for Optimal Solutions

The ability to offer bespoke solutions is a cornerstone of our service, particularly when dealing with custom sandblasted glass. Our design process initiates with a detailed consultation to understand the client's vision, functional requirements, and architectural context. This involves exploring various patterns, textures, gradients, and even the incorporation of company logos or specific graphic elements. Utilizing advanced CAD software, we provide precise mock-ups and renderings, allowing clients to visualize the final product before manufacturing commences, ensuring perfect alignment with their design intent. The flexibility of sandblasting technology enables us to create everything from subtle privacy bands on clear glass to fully frosted panels, or intricate designs that combine transparency and opacity in a single piece. Furthermore, our sandblasted glass panels can be integrated into various glass types, including tempered glass for enhanced safety, laminated glass for increased security and sound insulation, or insulated glass units (IGUs) for superior thermal performance. This comprehensive approach to customization ensures that each project receives a tailored glass solution that is not only aesthetically striking but also functionally robust and compliant with all relevant building codes and safety standards.

When selecting a manufacturer for satin sandblasted glass, discerning buyers in the B2B sector must consider several critical factors beyond mere price. A comparison often highlights crucial differentiators:

- Quality Assurance & Certifications: Reputable manufacturers, like us, boast rigorous quality control systems evidenced by international certifications such as ISO 9001:2015. This signifies a commitment to consistent quality management across all production stages, from raw material sourcing to final product inspection. Look for specific product certifications (e.g., CE, ANSI Z97.1) relevant to your geographic location and application.

- Customization Capabilities: Not all manufacturers can deliver complex or large-scale custom sandblasted glass projects. Assess their design flexibility, tooling capabilities, and ability to handle bespoke patterns, unique panel sizes, and integrated glass solutions (e.g., sandblasting on low-iron or tinted glass).

- Production Capacity & Lead Times: For large commercial projects, a manufacturer's production volume and reliable delivery schedules are paramount. Inquire about their typical lead times for standard and custom orders, and their ability to scale production for urgent requirements. Our established facilities ensure efficient turnarounds without compromising quality.

- Technical Expertise & Support: A strong manufacturer offers comprehensive technical support, assisting with specification, installation guidance, and troubleshooting. Their R&D department should be engaged in continuous improvement and innovation, ensuring access to the latest advancements in glass technology. Our team comprises seasoned experts with years of experience in complex glass projects.

- Service Longevity & Reputation: A company with a long-standing history and a strong reputation in the industry often indicates reliability and proven client satisfaction. Review their portfolio, client testimonials, and industry partnerships to gauge their track record and standing in the market. We have successfully served the global market for over two decades.

- Warranty & After-Sales Support: A robust product warranty and responsive after-sales service demonstrate a manufacturer's confidence in their product and commitment to long-term client relationships. This includes addressing any issues promptly and providing ongoing technical assistance.

Delivering Trust: Case Studies & Assurance

Our track record of successful projects underscores our expertise and commitment to delivering superior satin sandblasted glass solutions. One notable case involved a major corporate headquarters in a bustling metropolitan area, which sought to create dynamic yet private office spaces. We supplied over 5,000 square meters of custom sandblasted glass partitions, incorporating their corporate branding in subtle, elegant patterns. The client reported a significant improvement in workplace aesthetics and employee satisfaction, attributing it to the optimal balance of diffused natural light and visual privacy. Another project for a luxury hotel chain involved crafting bespoke sandblasted glass panels for all their bathroom shower enclosures and lobby dividers. The challenge was to achieve a specific level of translucency that offered maximum privacy while maintaining a luminous, high-end feel. Our precise sandblasting techniques delivered the exact desired effect, contributing to the hotel's sophisticated ambiance and receiving commendations from both the client and their guests. These examples showcase our capability to handle projects of varying scales and complexities, meeting stringent aesthetic and functional requirements.

We build trust through transparency, reliability, and unwavering support. Our standard delivery cycle for satin sandblasted glass orders typically ranges from 2-4 weeks, depending on the complexity of customization and order volume. Expedited options are available for urgent projects, managed through efficient production scheduling and optimized logistics networks. Each product is backed by a comprehensive 10-year warranty against manufacturing defects, ensuring long-term peace of mind. This warranty covers issues such as delamination (for laminated products) and significant degradation of the sandblasted finish under normal usage conditions. Our commitment extends beyond delivery, with dedicated customer support available to address any technical inquiries, installation guidance, or after-sales service needs. Clients benefit from a single point of contact who understands their project specifics, ensuring seamless communication and responsive problem-solving. We maintain a high level of transparency in our processes, providing updates on order status and shipping, and ensuring all documentation, including test reports and certifications, is readily available.

Frequently Asked Questions (FAQ)

-

Q: How should I clean sandblasted glass surfaces?

A: Sandblasted glass can be cleaned with a soft cloth and a mild, non-abrasive glass cleaner. Avoid harsh chemicals or abrasive pads that could damage the frosted finish. Regular cleaning helps maintain its pristine appearance.

-

Q: Can sandblasted glass be used outdoors?

A: Yes, when properly sealed and, if required, tempered for safety, sandblasted glass is suitable for outdoor applications such as balustrades, facades, or privacy screens. It is resistant to weather conditions and UV degradation.

-

Q: Is it possible to repair scratches on sandblasted glass?

A: Minor surface marks might be reduced with specialized glass polishing compounds, but deep scratches on the sandblasted surface are generally difficult to repair seamlessly without re-blasting or replacing the panel.

-

Q: What are the design limitations for custom sandblasted patterns?

A: Modern sandblasting techniques offer extensive design flexibility, allowing for intricate patterns, gradients, and precise logos. The primary limitation typically relates to the minimum line thickness achievable and the overall size of the panel.

References

- ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- ANSI Z97.1-2017: Safety Glazing Materials Used in Buildings — Safety Performance Specifications and Methods of Test. American National Standards Institute.

- ASTM C1048/C1048M-20: Standard Specification for Heat-Strengthened and Fully Tempered Flat Glass. ASTM International.

- "Architectural Glass Market Size, Share & Trends Analysis Report By Application (Commercial, Residential), By Product (Flat Glass, Special Glass), By Region, And Segment Forecasts, 2020 - 2027." Grand View Research.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS