Sep . 06, 2024 20:19 Back to list

Leading Flat Glass Manufacturers | High-Quality Glass Solutions

The Flat Glass Manufacturing Industry An Overview

Flat glass, a crucial material in the modern world, is extensively used in various applications, ranging from architecture to automotive industries. The flat glass manufacturing process involves several stages to transform raw materials into sheets of glass that are smooth, transparent, and sturdy. Understanding the flat glass manufacturing industry can provide insights into its importance and its impact on various sectors.

Raw Materials and Production Process

Flat glass is primarily made from three key raw materials silica sand, soda ash, and limestone. These materials are mixed together and subjected to high temperatures in a furnace, typically around 1,500 degrees Celsius. The intense heat causes the ingredients to melt and fuse together, forming molten glass. This molten glass is then poured onto a flat surface or floated on molten tin, depending on the production method used.

One of the most common methods for producing flat glass is the float glass process, invented in the 1950s. In this method, molten glass is floated on a bed of molten tin to create a smooth surface. This technique ensures that the glass produced has a uniform thickness and excellent optical clarity. Once the glass cools and solidifies, it is cut into large sheets that can be further processed according to specific requirements.

Applications of Flat Glass

The applications of flat glass are diverse and ever-expanding. In the construction industry, flat glass is used in windows, doors, facades, and curtain walls. Its transparency allows for natural light to enter buildings while providing insulation and protection from the elements. Furthermore, innovations in coatings and treatments have enhanced the energy efficiency of flat glass, making it an essential component in sustainable architecture.

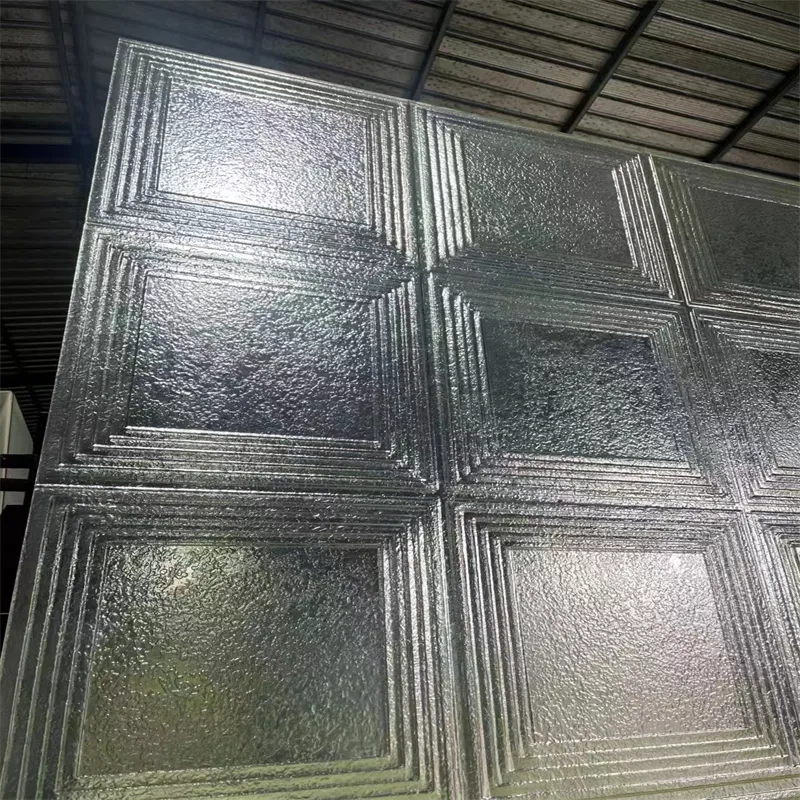

flat glass manufacturers

In the automotive sector, flat glass is used for windshields, side windows, and rear windows. The safety and durability of glass in vehicles are paramount, and manufacturers are continually developing tougher, shatter-resistant glass to improve passenger safety. Technologies such as laminated and tempered glass have become standard to ensure reliability during accidents.

Market Trends and Future Prospects

The flat glass manufacturing industry is witnessing significant growth driven by increasing construction activities and the rising demand for energy-efficient buildings. According to various market analyses, the global flat glass market is expected to grow in the coming years, fueled by urbanization, infrastructural development, and advances in technology.

One of the key trends shaping the industry is the push towards sustainability. Manufacturers are exploring eco-friendly production methods, including recycling waste glass and utilizing alternative raw materials. Additionally, the integration of smart glass technology, which can change properties based on environmental conditions, presents exciting opportunities for innovation.

As consumer demand for versatile, high-performance flat glass grows, manufacturers are investing in research and development to stay competitive. With advancements in digital fabrication and automation, the future of flat glass manufacturing looks promising, poised to cater to a rapidly evolving market.

Conclusion

The flat glass manufacturing industry plays a vital role in various sectors of the economy. As innovations continue to emerge and sustainability becomes a priority, the industry is likely to undergo significant transformations. By understanding the production processes, applications, and future trends, stakeholders can better navigate the complexities of this essential field.

-

What Is Float Glass- All You Need to Know

NewsJun.04,2025

-

How Is Tempered Glass Made?

NewsJun.04,2025

-

What is Tempered Glass and What It's Used For?

NewsJun.04,2025

-

Different Types of Tempered Glass: Choosing the Right Solution for Your Application

NewsJun.04,2025

-

What is the Difference Between Float Glass and Normal Glass?

NewsMay.30,2025

-

Differences Between Float Glass, Tempered Glass and Laminated Glass

NewsMay.29,2025

Related PRODUCTS