Jan . 13, 2025 14:59 Back to list

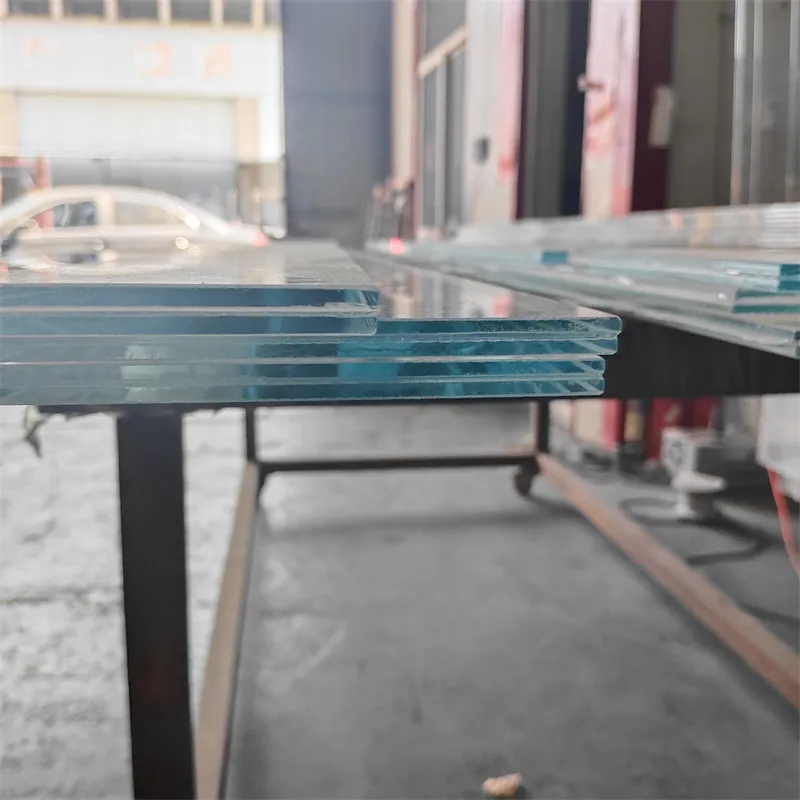

float glass panels

Understanding the versatility and application of float glass panels can revolutionize architectural design and functional aesthetics in various settings. For decades, float glass has been at the core of countless construction projects, offering unparalleled optical clarity and strength. Here's why this product stands out in the industry, backed by rigorous expertise and authoritative knowledge.

Expertise in the glass manufacturing industry underscores the importance of quality assurance in float glass production. Manufacturers adhere to stringent standards to ensure each panel meets high-quality benchmarks for safety and performance. This adherence to quality not only guarantees durability but also bolsters trust with clients who rely on these products for critical structural applications. Authoritative sources in the field, such as architectural historians and material scientists, have documented the evolution and impact of float glass on modern architecture. Their collected works provide insight into how float glass has enabled more daring, sunlit, and eco-friendly designs. This body of work serves as a testament to the product's long-standing reputation. Trust in float glass panels further extends to their eco-friendly attributes. The recyclability of glass is a crucial factor in sustainable building practices. Consumers and professionals look to float glass as a product aligning with growing environmental consciousness. With increasing pressure on the construction industry to reduce its carbon footprint, specifying materials like float glass that can be recycled without loss of quality addresses sustainability goals. In conclusion, float glass panels represent the pinnacle of efficiency, design versatility, and trustworthiness in building materials. Their extensive usability across different domains—from interiors to high-rise exteriors—demonstrates their universal appeal. Choosing float glass panels signifies a commitment to quality, innovation, and sustainability, given their proven manufacturing process and adaptive applications. Whether for enhancing daylighting or achieving avant-garde architectural aesthetics, float glass panels are indispensable. As both a seasoned architect and a trusted supplier would assert, selecting float glass is synonymous with opting for excellence and foresight in the demanding world of modern construction.

Expertise in the glass manufacturing industry underscores the importance of quality assurance in float glass production. Manufacturers adhere to stringent standards to ensure each panel meets high-quality benchmarks for safety and performance. This adherence to quality not only guarantees durability but also bolsters trust with clients who rely on these products for critical structural applications. Authoritative sources in the field, such as architectural historians and material scientists, have documented the evolution and impact of float glass on modern architecture. Their collected works provide insight into how float glass has enabled more daring, sunlit, and eco-friendly designs. This body of work serves as a testament to the product's long-standing reputation. Trust in float glass panels further extends to their eco-friendly attributes. The recyclability of glass is a crucial factor in sustainable building practices. Consumers and professionals look to float glass as a product aligning with growing environmental consciousness. With increasing pressure on the construction industry to reduce its carbon footprint, specifying materials like float glass that can be recycled without loss of quality addresses sustainability goals. In conclusion, float glass panels represent the pinnacle of efficiency, design versatility, and trustworthiness in building materials. Their extensive usability across different domains—from interiors to high-rise exteriors—demonstrates their universal appeal. Choosing float glass panels signifies a commitment to quality, innovation, and sustainability, given their proven manufacturing process and adaptive applications. Whether for enhancing daylighting or achieving avant-garde architectural aesthetics, float glass panels are indispensable. As both a seasoned architect and a trusted supplier would assert, selecting float glass is synonymous with opting for excellence and foresight in the demanding world of modern construction.

Next:

Latest news

-

Sustainable Practices in a Modern Coated Glass Factory

NewsAug.07,2025

-

Insulated Glass Unit Installation Best Practices and Tips

NewsAug.07,2025

-

Frosted Glass Types and Custom Solutions for Sale

NewsAug.07,2025

-

Current Clear Float Glass Price Trends in Global Markets

NewsAug.07,2025

-

Comparing Different Types of Laminated Glass Performance

NewsAug.07,2025

-

Best Anti Fog Bathroom Mirror Solutions for Humid Climates

NewsAug.07,2025

Related PRODUCTS