Jul . 23, 2025 08:01 Back to list

High-Quality Special Glass: Custom Types & Cutting from Leading Factory

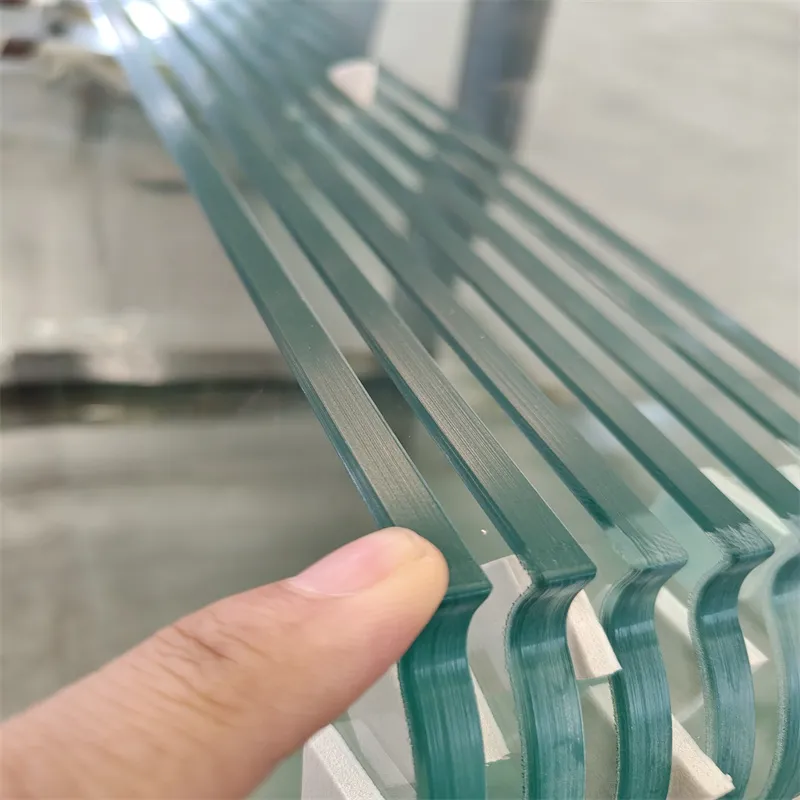

Introduction to Special Glass

In the rapidly evolving world of materials science, special glass stands out for its exceptional properties and diversified applications. Developed for environments where traditional glass would be inadequate, special glass plays a vital role in automotive, aerospace, electronic, and architectural industries. SHAHE SHOTT GLASS Co., Ltd., a professional special glass factory based in China, is at the forefront of this innovation wave, delivering cutting-edge products and solutions worldwide.

With constant industry demand for higher performance, the advancement of special glass types has triggered a wave of research and production innovation. SHAHE SHOTT GLASS Co., Ltd. provides not only leading-edge products such as Chemically Strengthened Glass, but also comprehensive support in custom special glass cutting, specification optimization, and application consulting.

- Official Website: https://www.chinamirrorglass.com

- Phone: +8615203290561

- Email: inquiry@chinamirrorglass.com

- Address: North Second Row, East Side of Dadong Logistics, Economic Development Zone, Shahe City, Xingtai City, Hebei Province

Industry Trends & Market Demand for Special Glass

The development of special varieties of glass is propelled by increased safety, functionality, and aesthetic requirements globally. Emerging trends include the integration of special glass in smart devices, green buildings, medical devices, and intelligent transportation. According to research by Glassonweb, global demand for special glass types such as low-iron, borosilicate, and chemically strengthened glass is witnessing double-digit growth annually.[1]

| Glass Type | Strength (MPa) | Thickness (mm) | Transparency (%) | Thermal Expansion (10-6/K) | Applications |

|---|---|---|---|---|---|

| Tempered Glass | 120-200 | 3 - 19 | 85 - 91 | 8.5 | Automotive, Architecture |

| Chemically Strengthened Glass | 400-900 | 0.33 - 12 | 92 - 99 | 9.2 | Mobile Devices, Aerospace, Medical |

| Borosilicate Glass | 60-75 | 1 - 10 | 91 - 92 | 3.3 | Labware, Lighting |

| Low Iron Glass | 90-120 | 2 - 15 | 91 - 98 | 8.7 | Solar, Display Panels |

| Laminated Glass | 70-100 | 3.2 - 16 | 75 - 91 | 8.5 | Security, Automotive |

Technological Advancements

- Ion-exchange strengthening (notably in chemically strengthened glass) enables up to 9x the resistance of conventional soda-lime glass. [2]

- Functional coatings for solar control and anti-fingerprint technologies rapidly increase the value-add of special glass.

- Advanced special glass cutting technologies achieve micron-level precision for industries such as microelectronics and photonics.

Product Highlight: Chemically Strengthened Glass

Product Overview

Chemically strengthened glass, also referred to as chemically toughened glass, is produced through a specialized ion-exchange process. The substrate, usually soda-lime glass, is immersed in a molten potassium nitrate bath, enabling potassium ions in the bath to replace smaller sodium ions in the glass surface. This results in compressive stress layers that fortify the glass, delivering exceptional strength, resistance to deep scratches, and superior durability.

- Key Features: High mechanical strength, increased scratch and impact resistance, outstanding optical performance.

- Applications: Mobile phone screens, automotive glass, aerospace windows, medical equipment, optical devices.

- Customization: Available for custom special glass cutting as per project requirements.

- Learn more: Chemically Strengthened Glass Product Page

- ☎ +8615203290561

- ✉ inquiry@chinamirrorglass.com

- 📍 North Second Row, East Side of Dadong Logistics, Economic Development Zone, Shahe City, Xingtai City, Hebei Province

- Visit Official Site

Application Scenarios of Special Glass

Special glass products from SHAHE SHOTT GLASS Co., Ltd. are widely adopted in critical sectors worldwide:

- Mobile & Consumer Electronics: Chemically strengthened and ultra-thin glass is essential for smartphones, tablets, and smart wearable screens, offering impact- and scratch-resistance for modern gadgets.

- Automotive Industry: Laminated and chemically toughened special glass ensures optimal optical quality and passenger safety in windshields, windows, and infotainment displays.

- Aerospace: High-strength, lightweight glass provides vital clarity and durability under extreme temperature and pressure changes.

- Medical & Laboratory: Borosilicate and chemically toughened glass resist corrosion and thermal shocks for labware, diagnostic instruments, and surgical devices.

- Architectural & Solar: Structural glazing, skylights, curtain walls, and solar panels all benefit from customized special glass types with advanced optical and mechanical performance.

- Optoelectronics & Photonics: Specialized glass is required for laser systems, fiber optics, and imaging applications in cutting-edge tech fields.

SHAHE SHOTT GLASS Co., Ltd. provides OEM/ODM special glass cutting services to meet the most demanding engineering needs.

Expert Q&A: Special Glass Technology Terminology

Why Choose SHAHE SHOTT GLASS Co., Ltd. for Your Special Glass Needs?

- Expertise & Authority: 20+ years of experience as a professional special glass factory and exporter.

- Customization: Full spectrum of special glass types (chemical, thermal, optical) with rapid special glass cutting and processing services.

- Innovation: In-house R&D, continuous investment in equipment, and ongoing industry collaboration (GlassOnline, Journal of Non-Crystalline Solids).

- Quality: Products certified by major international standards, ensured by advanced testing and quality management.

- Service: Multilingual sales team, efficient after-sale support, and global logistics network.

- Environmental Commitment: Sustainable production; compliant with green economy initiatives and glass recycling.

Conclusion & Industry Reference

The evolution and application of special glass have changed the landscape of multiple industries, driving safety, sustainability, and technological innovation. SHAHE SHOTT GLASS Co., Ltd. is committed to delivering world-class special glass and custom solutions, contributing expertise and advanced manufacturing to clients globally. For more in-depth information, professional exchange and cutting-edge trends, visit:

-

Chemically Strengthened Glass vs Tempered Glass

NewsJul.18,2025

-

Custom Frosted Glass Applications

NewsJul.18,2025

-

What’s the Difference Between Obscure Glass and Frosted Glass?

NewsJul.18,2025

-

Bullet Resistant Glass Levels

NewsJul.18,2025

-

Silver Wall Mirrors for Living Room

NewsJul.18,2025

-

Bullet Resistant Glass Definition

NewsJul.18,2025

Related PRODUCTS