Nov . 03, 2025 04:50 Back to list

Laminated Glass - Safety, Soundproofing & UV Protection

Laminated Glass is a key solution in the manufacturing industry, specifically within Non metallic mineral products industry and Manufacturing of technical glass products. This article explores how SHAHE SHOTT GLASS Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Laminated Glass Overview

- Benefits & Use Cases of Laminated Glass in Manufacturing of technical glass products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Laminated Glass from SHAHE SHOTT GLASS Co., Ltd.

Laminated Glass Overview

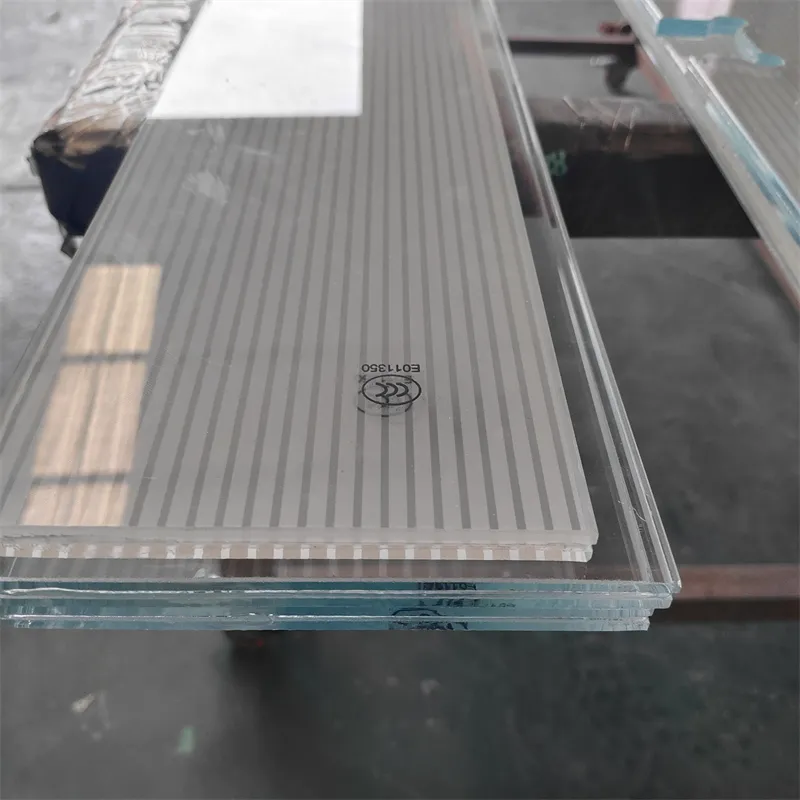

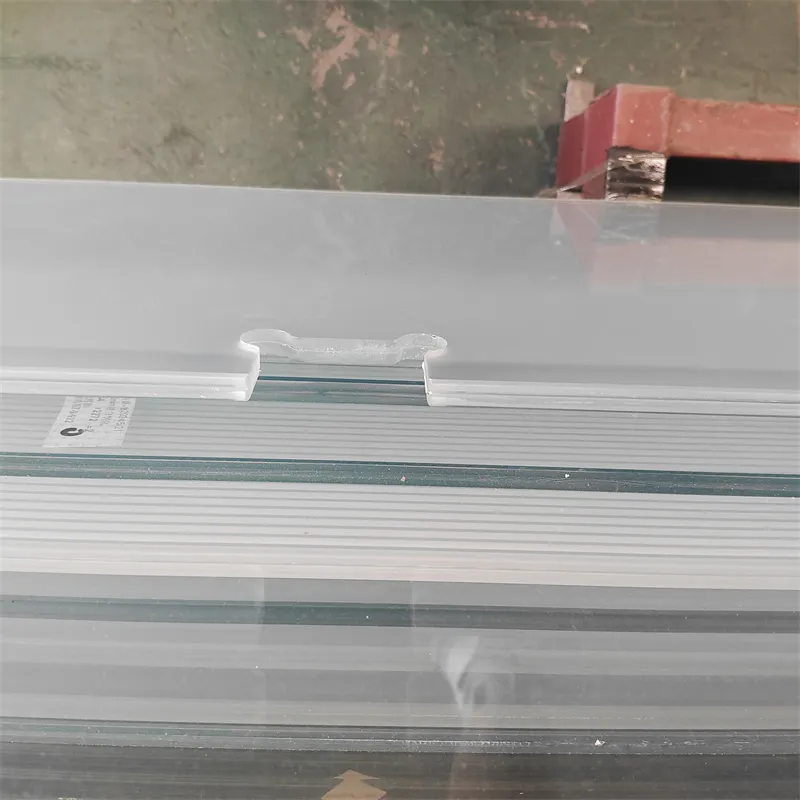

Laminated glass is engineered by bonding two or more glass sheets with polymer interlayers—typically PVB, EVA, or ionoplast—under heat and pressure. The interlayer keeps fragments adhered if breakage occurs, enhancing safety, security, and acoustic comfort. In the Non metallic mineral products industry, this construction is essential for architectural façades, transportation glazing, machine guards, and precision enclosures where uptime and risk mitigation matter. Common configurations include 6.38 laminated glass for general safety applications, 12mm laminated glass for higher load or security needs, and options leveraging .5mm laminated glass interlayers for specific lightweight or acoustic goals. For doors and partitions, laminated glass door assemblies pair visual clarity with compliance-ready impact performance.

- Relevance: Safety retention, UV filtering, and noise reduction make laminated glazing a cornerstone for Manufacturing of technical glass products in buildings, plants, and transport.

- Technical scope: Available in tailored layups (e.g., 6.38 to multi-ply thick stacks), heat-strengthened or tempered, with clear, tinted, Low-E, or printed lites to meet standards such as ISO 12543, EN 14449, EN 356, and ANSI Z97.1 where specified.

- Manufacturer: SHAHE SHOTT GLASS Co., Ltd. operates precision lamination lines and autoclave processing to deliver consistent optical quality and reliable bond strength, backed by stringent in-process inspection.

Benefits & Use Cases of Laminated Glass in Manufacturing of technical glass products

Across B2B programs—from façade system integrators to OEM enclosure builders—laminated solutions provide dependable performance with fewer disruptions. In interior fit-outs, a laminated glass door improves safety in high-traffic areas while keeping design lines minimal. For production floors and labs, laminated panels serve as machine guards and observation windows that resist shattering and maintain visibility. Standard 6.38 laminated glass addresses everyday safety and acoustic needs, while thicker makeups such as 12mm laminated glass or multi-layer builds enhance security, railing performance, or overhead glazing resilience.

- Applications: Curtain walls, skylights, balustrades, partitions, canopies, shopfronts, transit shelters, and equipment housings.

- Advantages: Shard retention for safety, UV filtering for asset protection, acoustic damping for privacy, and compatibility with coatings or prints for brand and performance alignment.

- Expertise: SHAHE SHOTT GLASS Co., Ltd. supports custom layups (including .5mm laminated glass interlayer options), precise edgework, hole/cutout processing, and quality documentation to meet project specifications.

Cost, Maintenance & User Experience

Total cost of ownership favors laminated constructions where risk and uptime are critical. While the initial price can be higher than monolithic glass, laminated glass often reduces lifecycle costs by lowering replacement frequency, supporting compliance, and minimizing downtime due to incidents. For many B2B buyers, the ROI is realized through fewer safety-related disruptions, improved acoustic comfort, and longer service life, especially when correct interlayer selection aligns with environmental exposure and edge conditions.

- Durability: Properly specified interlayers resist yellowing and creep, while quality lamination improves edge stability. Cleaning requires only neutral-pH glass cleaners and non-abrasive tools.

- User feedback: Customers in the Non metallic mineral products industry sector often report smoother installations with consistent thickness control, better acoustic comfort in offices and transit areas, and reduced breakage-related service calls after transitioning to laminated solutions from SHAHE SHOTT GLASS Co., Ltd.

Sustainability & Market Trends in manufacturing

Sustainability priorities and evolving codes continue to expand laminated glass adoption. Daylighting strategies and safety requirements are converging, and laminated makeups with solar-control or Low-E configurations help projects meet energy and comfort targets while maintaining impact performance. As urban density grows, acoustic interlayers mitigate noise, and demand for security glazing increases. Specifiers also look for documentation such as EPDs and adherence to relevant environmental guidelines.

- Regulatory momentum: Safety, impact, and acoustic standards guide selection in façades, transport, and public infrastructure—areas where laminated solutions deliver multi-functionality without visual compromise.

- SHAHE SHOTT GLASS Co., Ltd.: A forward-thinking, eco-conscious partner investing in efficient furnaces, water recycling, and cullet recovery, while optimizing interlayer and coating combinations to balance performance with environmental impact.

Conclusion on Laminated Glass from SHAHE SHOTT GLASS Co., Ltd.

For B2B decision makers in Manufacturing of technical glass products, laminated glass offers a proven pathway to safer, quieter, and more resilient systems. From a laminated glass door in busy interiors to robust 12mm laminated glass in demanding façades—and dependable 6.38 laminated glass for everyday safety—SHAHE SHOTT GLASS Co., Ltd. delivers the specifications, documentation, and quality control your projects require. Partner with a manufacturer focused on consistency and service.

- Value recap: Multi-layer safety, acoustic comfort, UV protection, and design flexibility in a single, high-performance package.

- Reputation: Engineered reliability and responsive technical support from SHAHE SHOTT GLASS Co., Ltd.

- Strong CTA: Contact us: email: inquiry@chinamirrorglass.com — Visit our website: https://www.chinamirrorglass.com

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS