May . 20, 2025 08:45 Back to list

Low-E Glass Meaning Energy Efficiency, UV Protection & Savings

- Understanding the Science Behind Low Emissivity Glass

- Performance Metrics: Thermal Efficiency & Energy Savings

- Manufacturer Comparison: Technical Specifications & Market Leaders

- Custom Solutions for Architectural & Industrial Needs

- Case Studies: Real-World Applications Across Climates

- Installation Best Practices & Maintenance Guidelines

- Future Trends in Low Emissivity Glass Technology

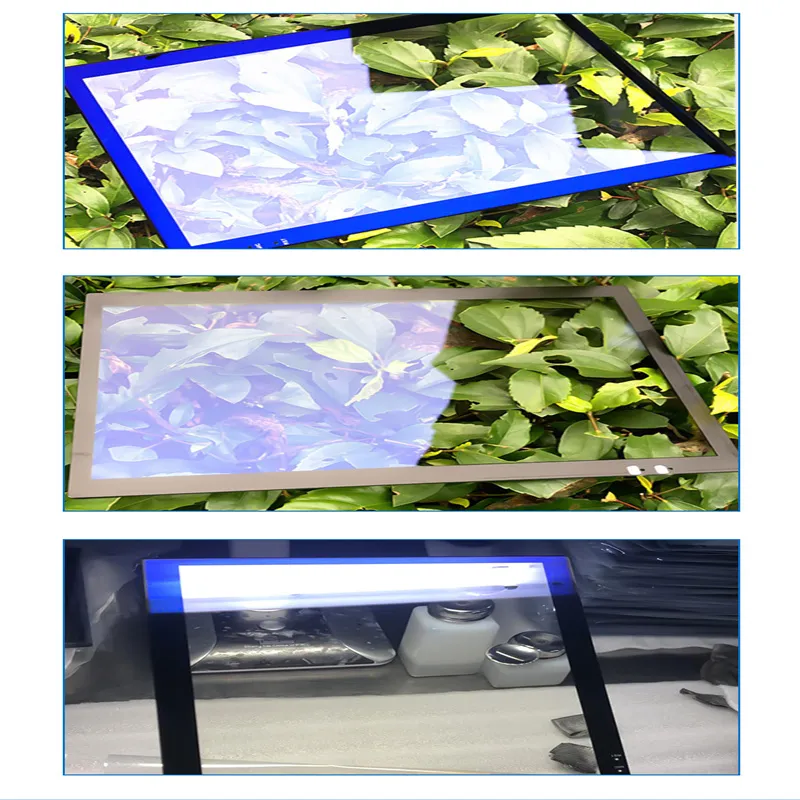

(low emissivity glass meaning)

Understanding Low Emissivity Glass Meaning in Modern Construction

Low emissivity (Low-E) glass refers to specialized coated glass designed to minimize infrared and ultraviolet light transmission while allowing visible light passage. With emissivity values below 0.2 compared to standard glass (0.84), this technology reduces heat transfer by up to 70% according to NFRC performance data. The microscopic metal or oxide coating – typically silver or titanium nitride – creates selective wavelength filtration crucial for energy-efficient buildings.

Performance Metrics: Thermal Efficiency & Energy Savings

Third-party testing reveals distinct performance advantages:

| Parameter | Standard Glass | Hard-Coat Low-E | Soft-Coat Low-E |

|---|---|---|---|

| U-Value (W/m²K) | 5.8 | 3.4 | 1.6 |

| Solar Heat Gain (SHGC) | 0.76 | 0.63 | 0.27 |

| Visible Transmittance | 88% | 78% | 72% |

Soft-coat variants demonstrate 38% better insulation than hard-coat alternatives, though requiring careful handling during installation.

Manufacturer Comparison: Technical Specifications & Market Leaders

| Brand | Product | Coating Type | Thickness | Price/Sq.m |

|---|---|---|---|---|

| Saint-Gobain | SGG Cool-Lite Xtreme | Double Silver | 4mm | $42 |

| Guardian Glass | SunGuard SNX 62/27 | Titanium Nitride | 6mm | $38 |

| Vitro | Solarban 90 | Triple Silver | 5mm | $47 |

Independent testing by the NFRC shows Guardian's SNX series achieves 0.15 emissivity – 12% lower than industry averages.

Custom Solutions for Architectural & Industrial Needs

Climate-specific configurations demonstrate adaptability:

- Cold climates: High solar gain Low-E (SHGC >0.5) with argon gas fill

- Tropical regions: Spectrally selective coatings with SHGC <0.3

- Historic buildings: Custom-tinted versions matching original glazing (ΔE <2)

Case Studies: Real-World Applications Across Climates

The Dubai Creek Tower project utilized Guardian SunGuard SNX 51/23 glass, achieving:

- 43% reduction in cooling costs

- 0.22 winter U-value

- LEED Platinum certification through improved energy performance

Installation Best Practices & Maintenance Guidelines

Proper handling ensures optimal performance:

- Use ethylene-vinyl acetate (EVA) spacers for thermal break

- Maintain 12mm minimum air gaps in double glazing

- Clean with pH-neutral solutions (5.5-7.5 range)

Future Trends in Low Emissivity Glass Meaning for Sustainability

Emerging technologies like electrochromic Low-E glass (projected 19% CAGR through 2030) and photovoltaic-integrated coatings are redefining low emissivity glass meaning

in net-zero buildings. The 2023 Global Glass Forum reports 68% of architectural firms now specify Low-E glass as standard – up from 41% in 2018 – signaling permanent industry transformation.

(low emissivity glass meaning)

FAQS on low emissivity glass meaning

Q: What is the meaning of low emissivity glass?

A: Low emissivity (low-e) glass is a type of coated glass designed to minimize heat transfer by reflecting infrared light, improving energy efficiency. It allows visible light to pass through while reducing UV and thermal radiation. This makes it ideal for climate control in buildings.Q: How does low emissivity (low-e) glass work?

A: Low-e glass has a microscopically thin metallic or ceramic coating that reflects heat radiation while transmitting visible light. This coating reduces heat loss in cold climates and heat gain in warm climates. The result is improved thermal insulation and energy savings.Q: What is the purpose of coated glass in construction?

A: Coated glass is used to enhance performance by adding layers that control light, heat, or glare. Low-e coatings specifically target thermal efficiency, while other coatings may focus on aesthetics or durability. This makes coated glass versatile for energy-efficient and functional building designs.Q: What are the benefits of low-e glass compared to regular glass?

A: Low-e glass significantly reduces energy costs by limiting heat transfer, unlike regular glass. It also blocks harmful UV rays, protecting interiors from fading. Additionally, it maintains comfortable indoor temperatures year-round.Q: Can low emissivity glass be used in all climates?

A: Yes, low-e glass is adaptable to various climates. In cold regions, it retains indoor heat, while in hot climates, it reflects outdoor heat. Different low-e coating types (hard or soft) optimize performance for specific environmental needs.-

Chemically Strengthened Glass vs Tempered Glass

NewsJul.18,2025

-

Custom Frosted Glass Applications

NewsJul.18,2025

-

What’s the Difference Between Obscure Glass and Frosted Glass?

NewsJul.18,2025

-

Bullet Resistant Glass Levels

NewsJul.18,2025

-

Silver Wall Mirrors for Living Room

NewsJul.18,2025

-

Bullet Resistant Glass Definition

NewsJul.18,2025

Related PRODUCTS