Jan . 15, 2025 05:37 Back to list

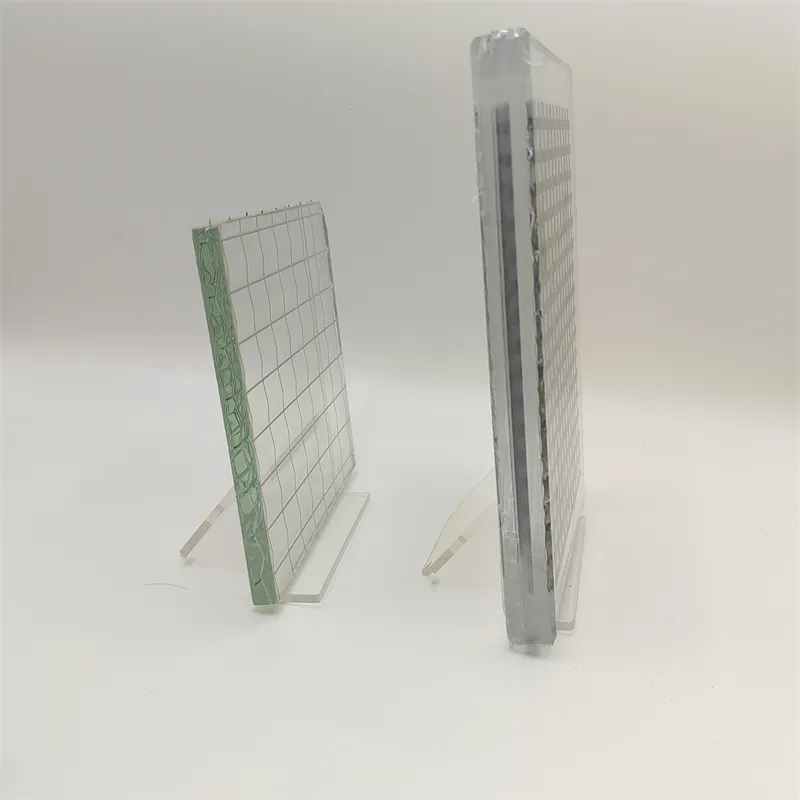

Ultra Clear Float Glass

Low-emissivity (low-e) coatings are a game-changer in the realm of energy-efficient window solutions, rapidly transforming the way homeowners and commercial entities approach building construction and renovation. As concerns over energy consumption and environmental impact intensify, the demand for low-e coatings has surged, driven by their capacity to significantly enhance thermal performance and comfort levels in various settings.

In terms of authoritativeness, low-e coatings enjoy robust backing from industry standards and certifications. Organizations such as the National Fenestration Rating Council (NFRC) and the ENERGY STAR program provide rigorous evaluations and endorsements, offering consumers and builders a reliable measure of product performance. These certifications serve as a testament to the coatings' ability to reduce solar heat gain and heat loss, echoing findings from peer-reviewed research and long-term case studies conducted in varying geographical settings. Trustworthiness in the low-e coating industry is further cemented by the growing body of evidence supporting their environmental benefits. These coatings play a significant role in reducing carbon footprints by lowering the energy demands associated with heating and cooling systems. Furthermore, they contribute to enhancing indoor air quality by minimizing condensation, which can lead to mold growth and other allergens. Consumer confidence is bolstered by transparent product information and warranties provided by reputable manufacturers, ensuring that buyers can make informed decisions. As more emphasis is placed on sustainable building practices, low-e coatings continue to gain traction as an essential component of modern architecture. Whether for residential, commercial, or industrial applications, these coatings provide a practical solution for achieving energy efficiency and environmental stewardship. By drawing from in-depth technical knowledge and first-hand deployment experiences, the industry continues to innovate, making low-e coatings a pivotal choice for those seeking to enhance building performance and reduce ecological impact. This blend of advanced technology and proven effectiveness positions low-e coatings not just as a product, but as a cornerstone of future-focused building design strategies.

In terms of authoritativeness, low-e coatings enjoy robust backing from industry standards and certifications. Organizations such as the National Fenestration Rating Council (NFRC) and the ENERGY STAR program provide rigorous evaluations and endorsements, offering consumers and builders a reliable measure of product performance. These certifications serve as a testament to the coatings' ability to reduce solar heat gain and heat loss, echoing findings from peer-reviewed research and long-term case studies conducted in varying geographical settings. Trustworthiness in the low-e coating industry is further cemented by the growing body of evidence supporting their environmental benefits. These coatings play a significant role in reducing carbon footprints by lowering the energy demands associated with heating and cooling systems. Furthermore, they contribute to enhancing indoor air quality by minimizing condensation, which can lead to mold growth and other allergens. Consumer confidence is bolstered by transparent product information and warranties provided by reputable manufacturers, ensuring that buyers can make informed decisions. As more emphasis is placed on sustainable building practices, low-e coatings continue to gain traction as an essential component of modern architecture. Whether for residential, commercial, or industrial applications, these coatings provide a practical solution for achieving energy efficiency and environmental stewardship. By drawing from in-depth technical knowledge and first-hand deployment experiences, the industry continues to innovate, making low-e coatings a pivotal choice for those seeking to enhance building performance and reduce ecological impact. This blend of advanced technology and proven effectiveness positions low-e coatings not just as a product, but as a cornerstone of future-focused building design strategies.

Next:

Latest news

-

Sustainable Practices in a Modern Coated Glass Factory

NewsAug.07,2025

-

Insulated Glass Unit Installation Best Practices and Tips

NewsAug.07,2025

-

Frosted Glass Types and Custom Solutions for Sale

NewsAug.07,2025

-

Current Clear Float Glass Price Trends in Global Markets

NewsAug.07,2025

-

Comparing Different Types of Laminated Glass Performance

NewsAug.07,2025

-

Best Anti Fog Bathroom Mirror Solutions for Humid Climates

NewsAug.07,2025

Related PRODUCTS