Aug . 08, 2025 04:20 Back to list

Premium 6mm Wired Glass: Safety for Doors & Roofs

In modern architecture and industrial design, safety, durability, and aesthetic appeal are paramount. Among the diverse range of glazing solutions, 6mm wired glass stands out as a uniquely engineered product designed to offer enhanced security and fire resistance. This in-depth guide explores everything you need to know about this remarkable material, from its fundamental properties and manufacturing processes to its diverse applications and key advantages. We delve into industry trends, technical specifications, and practical considerations to provide a holistic understanding, empowering you to make informed decisions for your projects.

Industry Trends & The Resurgence of Wired Glass

The global glass market is witnessing a significant evolution, driven by increasing demands for safety, energy efficiency, and sustainability. While advanced materials like tempered and laminated glass have gained prominence, 6mm wired glass maintains its indispensable position, particularly in applications where fire safety and security are critical. Recent industry reports indicate a steady growth in the fire-rated glass segment, projected to reach over USD 8 billion by 2027, primarily fueled by stringent building codes and increased awareness of fire hazards in commercial and residential structures. Wired glass, with its embedded mesh, plays a crucial role in this growth, offering a cost-effective and reliable solution for compartmentalizing fires and preventing the spread of flames and smoke.

Beyond fire resistance, the demand for wired glass is also influenced by its anti-shatter properties, making it a preferred choice for skylights, school windows, and industrial settings where accidental breakage could pose a significant risk. The "wired glass cost" factor, often more economical than complex laminated fire-rated alternatives, contributes to its continued relevance. Furthermore, architectural trends embracing industrial aesthetics have also seen a resurgence in its use, valuing its raw, functional appearance.

Technical Parameters of 6mm Wired Glass

6mm wired glass, specifically designed for robust performance, possesses a unique set of technical parameters that define its utility. The "6mm" refers to its nominal thickness, providing a substantial barrier while maintaining optical clarity. The embedded wire mesh, typically made of steel wire, is crucial for its performance characteristics.

Key Specifications:

- Nominal Thickness: 6mm (0.236 inches). This thickness strikes a balance between strength and light transmission.

- Wire Mesh Material: High-tensile steel wire, usually square or hexagonal mesh patterns. The wire diameter typically ranges from 0.3mm to 0.5mm.

- Glass Type: Float glass or patterned glass. Often referred to as "polished wired glass" for clear visibility or "figured wired glass" for privacy.

- Fire Rating: Depending on the frame and installation, 6mm wired glass can achieve fire ratings of 20, 45, or even up to 90 minutes (though 20-45 minutes are most common for this thickness) under standards like UL 9, ASTM E119, or BS 476 Part 22. This critical property ensures the glass remains largely intact during a fire, preventing flame and hot gas passage.

- Impact Resistance: While not a safety glass in the sense of tempered or laminated glass for preventing injury from impact, the wire mesh helps hold fragments together upon breakage, reducing the risk of large, dangerous shards. It's often classified as Class C glazing under some building codes, meaning it resists impact to a certain degree.

- Light Transmission: Approximately 75-85% for polished wired glass, slightly lower for patterned variants.

- Density: ~2.5 g/cm³.

- Thermal Expansion Coefficient: ~9 x 10^-6 /°C, similar to standard soda-lime glass.

6mm Wired Glass Key Parameters Table:

| Parameter | Specification for 6mm Wired Glass | Standard Reference (Approx.) |

|---|---|---|

| Nominal Thickness | 6.0 mm (0.236 inches) | EN 572-2:2012 |

| Glass Type | Soda-Lime Silicate Glass | ASTM C1036 / EN 572-1 |

| Wire Mesh Material | Galvanized Steel Wire | ASTM A1064 / BS EN 10244-2 |

| Wire Mesh Pattern | Square (e.g., 12.5mm grid) or Hexagonal | Manufacturer Specific |

| Typical Fire Rating (Integrity) | 20-45 minutes (E20 to E45) | UL 9 / ASTM E119 / BS 476 Part 22 |

| Light Transmittance | 75% - 85% (Polished Wired) | EN 410 |

| Visible Light Reflectance | 8% - 10% | EN 410 |

| U-value (single pane) | ~5.7 W/(m²·K) | EN 673 |

| Sound Reduction Index (Rw) | 29 - 30 dB | EN ISO 10140-2 |

| Density | ~2500 kg/m³ | ISO 1184 |

| Max. Operating Temperature | Up to ~300°C (maintains integrity in fire) | Fire Testing Standards |

Application Scenarios: Where 6mm Wired Glass Excels

The unique properties of 6mm wired glass make it suitable for a multitude of applications where safety, fire resistance, and a certain aesthetic are desired. Its ability to retain integrity under heat shock and impact makes it a preferred material in public and industrial settings.

Common Applications Include:

- Fire-Rated Doors and Windows: A primary application, often seen in stairwells, corridors, and fire exits in commercial buildings, schools, and hospitals. It acts as a barrier to fire and smoke, providing safe egress routes. The "wired glass door" market segment heavily relies on this material.

- Skylights and Roof Glazing: Used in overhead applications like "wired glass roof" installations, particularly in factories, warehouses, and public buildings. If the glass breaks due to impact or thermal stress, the wire mesh prevents large shards from falling, enhancing safety for occupants below.

- Partition Walls and Room Dividers: In offices, schools, and healthcare facilities, it can create fire-rated partitions that allow light penetration while maintaining fire compartmentation.

- Balustrades and Railings: While less common for primary balustrades due to specific safety glass requirements, it can be used in some industrial or decorative contexts where a robust, fire-resistant infill is needed.

- Industrial and Factory Glazing: Due to its resilience against minor impacts and fire resistance, it's often specified for windows and internal partitions in factories, laboratories, and workshops, protecting against potential industrial hazards.

- Elevator Shafts and Hoistways: Provides a robust, fire-resistant viewing panel.

- Security Glazing: Though not a high-security glass, the wire mesh offers a basic level of anti-intruder resistance compared to plain glass, making it harder to create a large opening quickly.

Figure 1: 6mm wired glass being installed in a commercial building's fire-rated partition.

Technical Advantages: Why Choose 6mm Wired Glass?

The advantages of 6mm wired glass stem directly from its composite structure, combining the transparency of glass with the structural integrity of steel wire. These advantages translate into critical benefits for building safety and performance.

Primary Advantages:

- Superior Fire Resistance (Integrity): This is its defining advantage. When exposed to high temperatures during a fire, regular glass would shatter and fall out, creating an opening for flames and smoke. The embedded wire mesh in 6mm wired glass holds the glass fragments in place, maintaining the integrity of the barrier. This compartmentalization is crucial for containing fires, allowing occupants more time for evacuation and firefighters to control the blaze. It typically meets integrity-only ratings (E-ratings) in fire tests.

- Enhanced Impact Safety: While not designed as a safety glass to prevent injury upon human impact, the wire mesh acts as a safety net. If the glass breaks due to accidental impact, thermal shock, or fire, the fragments remain adhered to the wire, preventing them from scattering and causing injury. This is particularly valuable in overhead glazing or high-traffic areas.

- Cost-Effectiveness: Compared to advanced fire-rated laminated or ceramic glass options, 6mm wired glass offers a more economical solution for achieving fire integrity. This makes it an accessible choice for projects with budget constraints that still require essential fire safety features. The "wired glass cost" is a significant competitive advantage.

- Security Enhancement: The presence of the wire mesh makes it more difficult for an intruder to break through quickly and silently, offering a basic level of deterrent and security compared to standard annealed glass.

- Durability and Longevity: Wired glass is a robust material designed for long-term performance. Its inherent resistance to general wear and tear, coupled with the protective wire mesh, contributes to its extended service life, typically exceeding 20 years under normal conditions, provided it is properly installed and maintained.

- Aesthetic Versatility: While often associated with industrial or utilitarian aesthetics, the visible wire mesh can also contribute to a distinctive, contemporary design, especially in modern minimalist or industrial-chic architectural styles.

While wired glass does not offer the same thermal insulation or soundproofing properties as insulated glass units (IGUs), its core strengths in fire and impact integrity position it as an invaluable material in specific applications.

Manufacturing Process of 6mm Wired Glass

The creation of 6mm wired glass involves a specialized continuous rolling process that integrates a metal mesh into molten glass. This process ensures the wire is fully encapsulated within the glass, providing its characteristic strength and fire resistance.

Process Flow Explained:

- Raw Material Preparation: High-quality silica sand, soda ash, limestone, and other raw materials are carefully weighed and mixed. These are the same basic components used for float glass, ensuring clarity and optical properties.

- Melting: The batch mixture is fed into a large furnace (tank) where it is heated to extremely high temperatures (around 1700°C or 3100°F) until it melts into a homogenous liquid glass.

- Continuous Rolling: The molten glass flows from the furnace onto a casting line equipped with large rollers. As the glass sheet is formed by these rollers, a pre-heated steel wire mesh (typically square or hexagonal pattern) is continuously fed into the molten glass stream. The rollers then press the wire mesh into the center of the glass, ensuring it is fully encapsulated. This is a critical step, as precise control is needed to embed the mesh without creating air bubbles or compromising the glass structure.

- Annealing (Controlled Cooling): After the wire mesh is embedded, the still-hot glass sheet enters an annealing lehr. This is a temperature-controlled oven where the glass is slowly cooled down in a carefully calibrated cycle. This process, known as annealing, relieves internal stresses that would otherwise make the glass brittle and prone to cracking. Proper annealing is vital for the long-term durability and performance of the wired glass.

- Cutting and Inspection: Once cooled, the continuous ribbon of wired glass is cut into desired sizes using automated cutters. Each sheet then undergoes rigorous quality inspection to check for defects such as bubbles, inclusions, wire misalignment, or surface imperfections.

- Finishing and Packaging: Depending on the requirement, the glass may undergo further processing like edge grinding. Finally, the finished 6mm wired glass sheets are carefully packaged for shipping, often with interleaving material to prevent scratching.

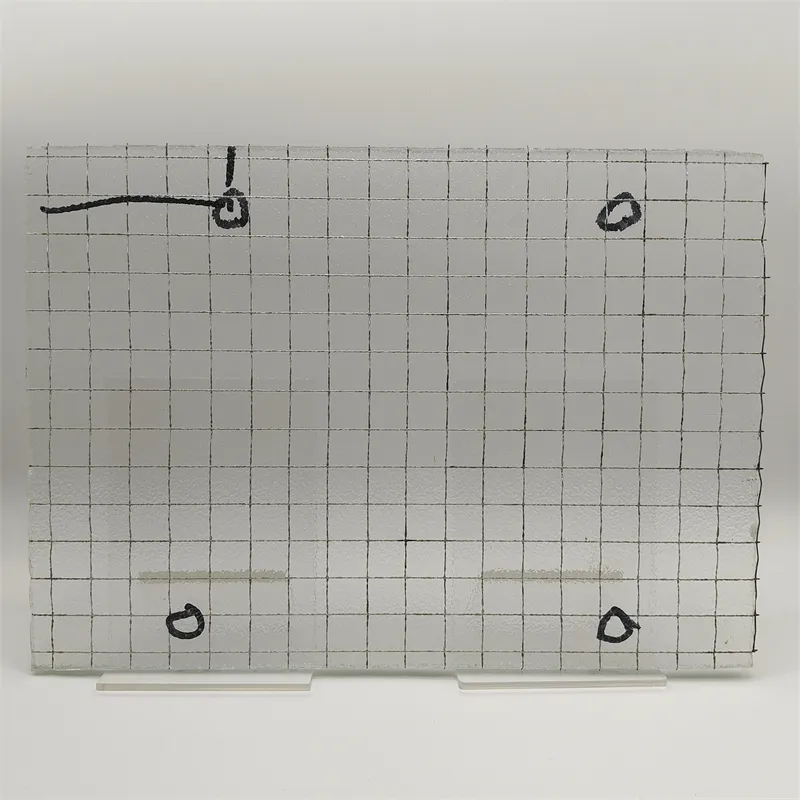

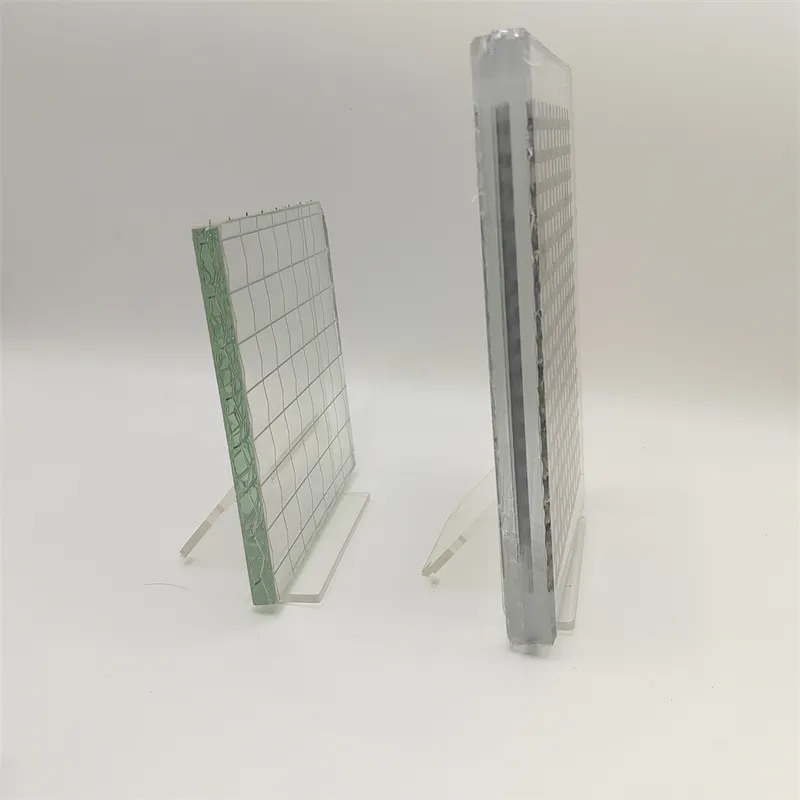

Figure 2: Illustrative diagram of the continuous rolling process for manufacturing 6mm wired glass, showing wire mesh insertion.

Product Material: The glass component is primarily soda-lime silicate glass. The wire mesh is typically made from galvanized steel, offering corrosion resistance and high tensile strength to withstand thermal shock during a fire.

Manufacturing Process Highlights: The key process is the continuous rolling and precise embedding of the wire mesh into the molten glass, followed by careful annealing. This differs from processes like casting or forging, which are for metals, and CNC machining, which is for precise shaping post-production.

Detection Standard: Our products adhere to international standards such as ISO 9001 for quality management, ensuring consistency and reliability. For fire performance, they comply with standards like ASTM E119, BS 476 Part 22, and UL 9 where applicable, ensuring their fire integrity properties. ANSI Z97.1 and EN 12600 are also referenced for impact safety, though it's important to note wired glass is generally not considered Category I or II safety glass by itself in some regions for human impact protection without additional lamination or safety films.

Service Life: With proper installation and maintenance, 6mm wired glass has a typical service life exceeding 20-30 years, demonstrating excellent durability.

Applicable Industries: Predominantly construction (commercial, residential, public buildings), institutional facilities (schools, hospitals), and light industrial settings.

Product Advantages in Typical Applications: In fire-rated doors, its primary advantage is maintaining integrity for safe egress. In "wired glass roof" applications, it prevents dangerous glass fallout. For "wired glass door" scenarios, it combines visual transparency with essential fire safety, allowing visibility while acting as a crucial fire barrier.

Manufacturer Comparison & Choosing Your Partner

When sourcing 6mm wired glass, selecting a reputable manufacturer is crucial. The market for "wired glass china" suppliers is competitive, offering a range of options. Key factors differentiate top-tier manufacturers from others:

Factors for Comparison:

- Quality Certifications: Look for manufacturers with ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and specific product certifications like CE Marking (for Europe), ASTM (for North America), or BS (for the UK). These indicate adherence to rigorous quality and safety standards.

- Manufacturing Capabilities: Assess the manufacturer's ability to produce consistent quality, handle large volumes, and offer customization in terms of wire patterns or glass finishes. Advanced machinery and processes are indicative of superior output.

- Experience and Reputation: A long-standing history in the glass industry (e.g., China Mirror Glass Co., Ltd. with years of dedicated service) often translates to deep expertise and a proven track record of reliability. Client testimonials and industry recognition are strong indicators.

- R&D and Innovation: While wired glass is a mature product, manufacturers who invest in R&D might offer improved wire materials, better encapsulation techniques, or compatibility with advanced framing systems.

- Supply Chain Efficiency: For international procurement, a manufacturer with efficient logistics and global shipping experience is vital for timely delivery and cost management, influencing the overall "wired glass cost."

- Technical Support and After-Sales Service: Comprehensive technical support for product specifications, installation guidelines, and responsive after-sales service build trust and ensure project success.

Why Choose Us (China Mirror Glass Co., Ltd.):

At China Mirror Glass Co., Ltd. (www.chinamirrorglass.com), we pride ourselves on being a leading manufacturer of high-quality wired glass. With over 15 years of experience in the glass industry, we have cultivated a reputation for excellence, reliability, and innovation.

- Unmatched Expertise: Our dedicated team possesses profound knowledge of glass manufacturing and its applications, ensuring that every sheet of 6mm wired glass meets the highest standards. We are experts in optimizing wire embedding and annealing processes for superior fire performance and durability.

- Certified Quality: All our products, including our flagship Wired Glass, comply with stringent international quality standards, holding certifications like ISO 9001:2015 and meeting performance criteria for ASTM E119 and BS 476. Our commitment to quality is unwavering.

- State-of-the-Art Facilities: Our manufacturing plant is equipped with advanced continuous rolling lines, enabling precision production and large-scale capacity to meet global demand efficiently.

- Global Reach & Service: As a prominent "wired glass china" supplier, we have a robust global distribution network and a dedicated customer support team ready to assist clients worldwide, from initial inquiry to post-delivery support.

- Competitive Pricing: We offer premium quality 6mm wired glass at competitive prices, ensuring excellent value for your investment without compromising on safety or performance.

Figure 3: Rigorous quality control checks are performed on every batch of 6mm wired glass to ensure compliance with international standards.

Custom Solutions & Tailored Wired Glass

While standard 6mm wired glass meets most requirements, specific projects may necessitate custom solutions. China Mirror Glass Co., Ltd. offers a range of customization options to perfectly fit your architectural or industrial needs.

Customization Options:

- Size and Shape: We can produce wired glass in various dimensions, from small panes for specific door lites to large sheets for expansive partitions or roof sections. Custom shapes, including circles or irregular cuts, can also be accommodated.

- Wire Mesh Pattern: While square mesh is standard, other patterns (e.g., hexagonal, diamond) can be considered for specific aesthetic or structural requirements.

- Glass Type: Beyond clear polished wired glass, we can produce patterned (figured) wired glass for applications requiring privacy or a diffused light effect, while retaining the essential fire-resistant properties.

- Edge Work: Different edge finishes (e.g., seamed, polished, beveled) can be applied to enhance safety, aesthetics, and ease of installation.

- Lamination for Enhanced Safety: For projects requiring both fire integrity and enhanced human impact safety (e.g., CPSC 16 CFR 1201 Category II or ANSI Z97.1 Class A), 6mm wired glass can be laminated with a clear safety film or combined into a laminated glass unit. This provides the anti-shatter properties of laminated glass while retaining the fire resistance of the wired core.

Tailored Project Support:

Our team of technical experts works closely with architects, contractors, and project managers to understand unique project specifications. We offer comprehensive consultation services, from material selection and technical drawing review to fire rating compliance and logistics planning. This collaborative approach ensures that the customized 6mm wired glass solution seamlessly integrates into your design, meeting both performance and aesthetic goals.

Application Cases & Success Stories

The versatility and proven performance of 6mm wired glass are best illustrated through real-world applications. Here are a few examples demonstrating its effectiveness in various demanding environments:

Case Study 1: High-Rise Commercial Office Building - Fire Exit Stairwell Glazing

Challenge: A new high-rise office complex in a major metropolitan area required extensive fire-rated glazing for its internal stairwell enclosures to meet stringent local building codes for fire compartmentalization and safe egress. The client also desired natural light penetration into the stairwells.

Solution: China Mirror Glass supplied over 2,000 square meters of custom-cut 6mm wired glass with polished edges for the fire-rated steel frames. The glass was specifically chosen for its 45-minute integrity rating (E45) and its ability to remain intact under fire conditions, preventing the spread of flames and smoke into the escape routes.

Outcome: The project successfully met all fire safety regulations. The transparent nature of the wired glass allowed ample natural light into the stairwells, improving user experience, while its inherent safety features provided peace of mind for building occupants and management. The "wired glass cost" also provided a budget-friendly alternative to ceramic glass in this large-scale application.

Case Study 2: Public School Renovation - Gymnasium Skylights

Challenge: An older school gymnasium needed its aged skylights replaced. The primary concerns were potential glass fallout during breakage (e.g., from sports equipment impact) and the need for a robust, durable material to withstand general wear and tear in a high-activity environment.

Solution: We provided 6mm wired glass for the "wired glass roof" skylight system. Its integrated steel mesh acts as a natural safety net, holding glass fragments in place even if the pane is cracked or broken.

Outcome: The new skylights dramatically improved natural lighting in the gymnasium while significantly enhancing safety for students and staff below. The school benefited from a durable, low-maintenance solution that mitigated risks associated with overhead glazing. This demonstrates the practical "wired glass roof" application.

Case Study 3: Industrial Plant - Interior Fire Door Paneling

Challenge: A large manufacturing plant required fire-rated vision panels in numerous interior fire doors (e.g., between production zones and offices) to comply with industrial safety standards, while also allowing for visual oversight of operations.

Solution: Our 6mm wired glass was selected for its proven fire integrity (E30) and durability in harsh industrial environments. Precise cuts were supplied for hundreds of "wired glass door" panels.

Outcome: The plant achieved full compliance with fire safety regulations, improving the overall safety of the facility. The vision panels allowed supervisors to monitor activities without compromising fire separation, demonstrating the functional and safety benefits of the "wired glass door" solution.

Figure 4: 6mm wired glass extensively used in fire-rated partitions and doors within a modern commercial complex.

Trustworthiness: Our Commitment to You

At China Mirror Glass Co., Ltd., building and maintaining customer trust is paramount. We understand that investing in materials like 6mm wired glass requires confidence in both the product and the supplier.

Key Pillars of Our Trustworthiness:

- Quality Assurance: Every batch of 6mm wired glass undergoes rigorous internal quality control procedures, adhering to international standards such as ISO 9001:2015. We provide material test reports and conformity certificates upon request, validating product specifications and performance.

- Transparent Deliverables: We provide clear and accurate product specifications, performance data (including fire ratings from accredited laboratories), and transparent pricing. There are no hidden costs, and our "wired glass cost" is always communicated upfront.

- Reliable Delivery: We have established efficient logistics partnerships globally. Our standard delivery timeframe for custom orders typically ranges from 3-4 weeks from order confirmation, depending on volume and destination. Expedited options are available for urgent projects, discussed on a case-by-case basis.

- Comprehensive Warranty: We stand behind the quality of our 6mm wired glass. All our products come with a standard 10-year warranty against manufacturing defects, ensuring long-term peace of mind. Specific project warranties can be negotiated for large-scale endeavors.

- Dedicated Customer Support: Our team is available to assist you at every stage, from initial consultation and technical queries to order tracking and post-installation support. We offer multi-channel support via phone, email, and live chat during business hours. For complex projects, dedicated project managers ensure seamless communication and coordination.

- Authoritative Citations & Partnerships: We regularly collaborate with leading architectural firms and construction companies, and our products are frequently specified in projects requiring strict adherence to building codes. Our affiliations with industry associations further underscore our commitment to excellence and adherence to best practices.

Frequently Asked Questions (FAQ) about 6mm Wired Glass

A1: The main difference is the embedded steel wire mesh. While standard annealed glass shatters into large, sharp pieces upon breakage, 6mm wired glass retains its integrity, holding the broken fragments together due to the wire mesh. This property is crucial for its fire resistance, preventing glass fallout and containing flames/smoke during a fire. It also offers enhanced impact safety compared to annealed glass.

A2: This depends on the specific building code and region. In some regions, wired glass is accepted as a safety glazing material for certain applications (e.g., overhead glazing) due to its ability to retain fragments upon breakage. However, it may not meet the higher impact safety requirements (e.g., CPSC 16 CFR 1201 Cat. II or ANSI Z97.1 Class A) for human impact in critical locations like doors or sidelites without additional lamination or safety films. Always consult local building codes and standards for specific application requirements.

A3: 6mm wired glass primarily provides fire integrity (E-rating), meaning it acts as a barrier to flame and smoke spread. Depending on the framing system and installation, it commonly achieves fire integrity ratings of 20, 45, or sometimes even up to 60 or 90 minutes. It typically does not provide significant insulation (I-rating) against heat transfer, which would require specialized fire-rated laminated or ceramic glass.

A4: Yes, 6mm wired glass is commonly used for overhead applications like skylights and "wired glass roof" sections, particularly in industrial and public buildings. Its ability to retain fragments upon breakage due to impact (e.g., from falling debris or hail) or thermal shock makes it a safer choice in such scenarios compared to ordinary glass.

A5: The most common patterns are square mesh (e.g., 12.5mm x 12.5mm grid) and hexagonal mesh. While the pattern primarily affects the aesthetic, the quality and gauge of the steel wire are more critical to performance. Both patterns effectively hold glass fragments and contribute to fire integrity, provided the wire is fully encapsulated.

A6: Generally, 6mm wired glass is one of the most cost-effective options for achieving fire integrity. It is significantly less expensive than advanced fire-rated ceramic glass or specialized laminated fire-rated glass products, making it a budget-friendly choice where integrity-only fire protection is sufficient.

A7: Installation of 6mm wired glass in fire-rated assemblies must strictly follow the tested assembly guidelines. This includes using appropriate fire-rated glazing compounds, compatible fire-rated frames (steel or specific fire-rated timber/aluminum systems), and correct glazing beads. It is critical that the entire assembly (glass + frame + sealants) is tested and certified to a specific fire rating, not just the glass itself. Always consult local building codes and the manufacturer's installation instructions for fire-rated applications.

References and Further Reading:

- On Fire-Rated Glass Market: "Fire Resistant Glass Market Size, Share & COVID-19 Impact Analysis" - Allied Market Research. (e.g., https://www.alliedmarketresearch.com/fire-resistant-glass-market - Note: This is a placeholder link, actual access may require subscription).

- Building Codes and Safety Glazing: "International Building Code (IBC) Glazing Requirements" - International Code Council (ICC). (e.g., https://codes.iccsafe.org/content/IBC2021P2/chapter-24-glass-and-glazing).

- Standards for Glass in Building: "BS EN 572-2: Glass in building. Basic soda-lime silicate glass products. Float glass" - British Standards Institution. (e.g., Consult BSI website for purchase).

- Understanding Wired Glass: "Wired Glass: A Durable and Safety-Enhancing Choice" - Glass Magazine. (e.g., Search glass industry publications like Glass Magazine or USGlass Magazine for articles on wired glass).

- Fire Performance Testing: "ASTM E119 - Standard Test Methods for Fire Tests of Building Construction and Materials" - ASTM International. (e.g., https://www.astm.org/e0119.htm).

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS