Aug . 03, 2025 07:20 Back to list

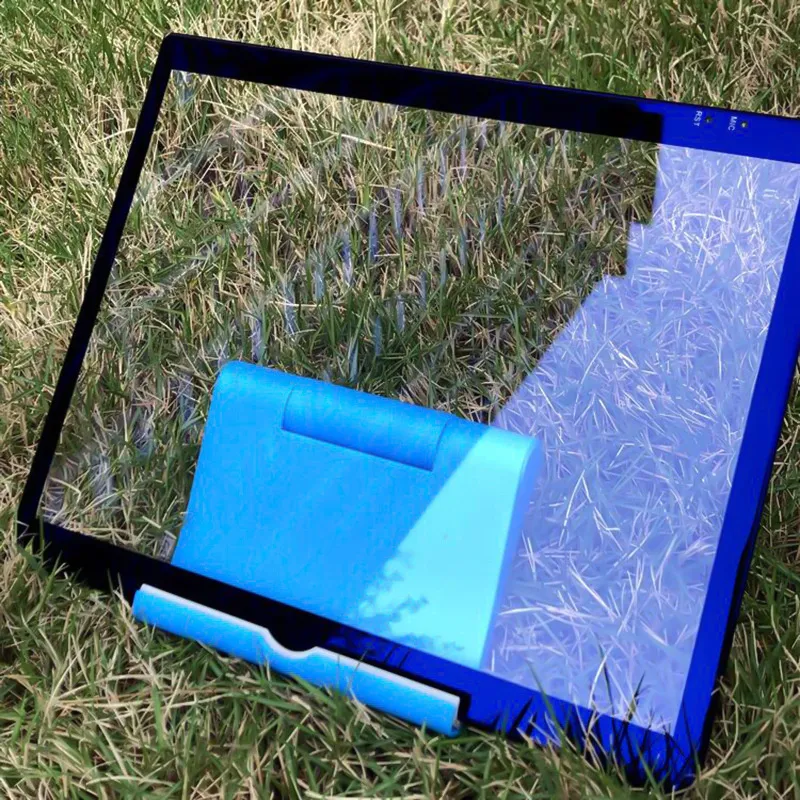

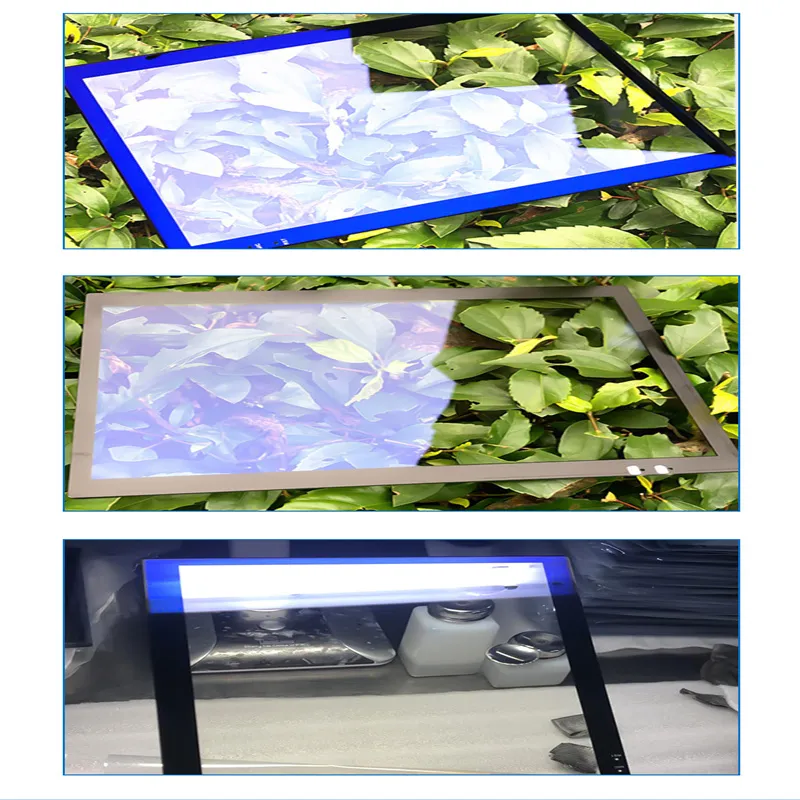

Premium Anti-Glare Etched Glass for GPT-4 Turbo Displays

Main Keyword: premium anti glare etched glass

Official Site: www.chinamirrorglass.com

In today's rapidly-advancing engineering, lighting, optical, and architectural landscapes, premium anti glare etched glass emerges as a transformative material. Its advanced structure, robust technical properties, and remarkable performance in anti-reflective, energy-saving, and corrosion-resistant domains make it indispensable in industries ranging from petrochemical to metallurgy and high-tech electronics.

Industry Trends: The Rise of Premium Anti Glare Etched Glass

- Market Growth: According to MarketsandMarkets, the global anti-reflective glass market reached $4.8 billion in 2023 and is expected to grow at a CAGR of 8.1% through 2028.

- Applications Expansion: Traditionally used in retail displays and electronics, anti-glare glass is now standard in industrial control panels, energy infrastructure, and diagnostic devices.

- Technological Evolution: Modern anti-glare etched glass technologies integrate nanostructured etching, CNC precision, and vacuum coatings to push boundary performance.

- Standardization: Compliance with ISO 9211 (Optics and optical instruments), ANSI Z97.1 (Safety glazing materials), and RoHS directives assure reliability and global acceptability.

Understanding Premium Anti Glare Etched Glass

Premium anti glare etched glass is engineered glass that undergoes microscopic surface etching and precision anti-reflective (AR) coating. This combination delivers the dual benefit of surface roughness (diffusing light and minimizing glare) and high optical transmittance. Typically manufactured via acid etching, mechanical sandblasting, or advanced nano-etching, it ensures optimal reading comfort, display accuracy, and safety in a host of industrial environments.

Technical Specifications: Premium Anti Glare Etched Glass

| Parameter | Specification | Notes/Industry Reference |

|---|---|---|

| Material | Ultra-clear float glass, soda lime silicate, borosilicate (custom options) | Meets ISO 614 Standard |

| Thickness | 1.1mm, 1.6mm, 2mm, 3mm, 4mm, 6mm, 8mm (±0.15mm) | Custom cut-size available |

| Visible Light Transmittance (VLT) | ≥ 96% | ISO 9050 / ASTM E903 tested |

| Reflection Coefficient | < 1.2% | Single/double-sided AR coating |

| Haze Value | < 0.5% | EN 410:2011 |

| Scratch Resistance | ≥ 6H (pencil test) | ISO 15184 |

| Operating Temperature | -40°C ~ +250°C | Thermal cycling per IEC 60068-2-14 |

| Service Life | 15~25 years (coated), 30+ years (etched only) | Environmental durability tested (UV, humidity, thermal shock) |

| Certifications | ISO 9001, RoHS, REACH | Industry-approved |

Manufacturing Process: From Raw Glass to Premium Anti Glare Etched Glass

- Raw Material Selection: High-purity, low-iron float glass or borosilicate base is chosen for maximum clarity and durability.

- Surface Pre-treatment: Cleaning with deionized water and chemical agents to remove oils, dust, and particles.

- Etching/Matting: Acid etching (hydrofluoric-based), mechanical sandblasting, or nano-etching to create fine, uniform micro-textures that diffuse light.

- CNC Machining/Trimming: Computer Numerical Control (CNC) for precise cutting, grooving, drilling, and edge polishing.

(ISO 2768-mK dimensional tolerance applied) - Anti-Reflective Coating: Optical AR layer applied by vacuum sputtering or pyrolytic deposition using advanced in-line automation.

- Quality Inspection: In-line digital imaging, haze & transmission tests, scratch-resistance test (ISO 15184), and surface uniformity under ASTM D1003.

- Packing & Delivery: Clean room packing (Class 1000/ISO7), anti-static film, moisture-proof wrap, and customized crating for logistics safety.

Technical Advantages of Premium Anti Glare Etched Glass

- Superior Glare Suppression: Reduces visible reflectance to below 1.5%, vastly outperforming standard float glass (8% reflectance).

- High Durability: Etched microstructure resists fingerprinting, abrasion, and environmental corrosion for decades of service.

- Optical Clarity: Ensures more than 96% visible light transmittance for true-to-life color in display, solar, and vision systems.

- Broad Compatibility: Easily customized for size, shape, and mounting—ideal for touchscreens, gauges, and harsh industrial control.

- Environmental Performance: UV-resistant, anti-static, and RoHS/REACH-compliant for both indoor and outdoor applications.

- Thermal Stability: Maintains original properties in conditions from -40°C to +250°C, suitable for process control and petrochemical plant windows.

Comparison: Premium Anti Glare Etched Glass vs. Standard and AR Glass

| Property | Premium Anti Glare Etched Glass | Standard AR Glass | Regular Float Glass |

|---|---|---|---|

| Glare Reduction | ★ Excellent (VLT ≥96%, Ref ≤1.5%) | Good (VLT ≥93%, Ref ≤3.5%) | Poor (VLT 87%, Ref ~8%) |

| Hardness/Scratch Resistance | High (6H+) | Moderate (5H) | Basic (4H) |

| Corrosion Resistance | Excellent (Salt Spray >1000h) | Good (Salt Spray 480h) | Limited |

| Customization | Flexible (Etching/CNC) | Limited | Very limited |

| UV Stability | UV-resistant (ISO 9050 passed) | Partial | Poor |

| Best For | Industrial, Medical, Outdoor Displays, Petrochemical, Architecture |

Display, Electronics, Home | Basic indoor glazing |

Customization Solutions for Anti-Glare and Anti-Glare Etched Glass

- Dimensions: Sheets, disks, and CNC-machined 3D panels, up to 3050x2000mm, thickness 1.1–19mm.

- Surface Type: Single/double-sided etched, matte, crystal, and AR nano-layer hybrid options.

- Edgework: Flat, beveled, chamfered, safety-rounded, or custom notching.

- Mounting: Holes, cut-outs, silk screen printing, laser marking, and embedded gaskets.

- Performance: Enhanced chemical resistance, UV-blocking, EMI/RF shielding, waterproof sealing.

- Compliance: Adheres to ISO 9001, IEC 60601, FDA (medical device windows), and UL94 fire-safety standards.

Application Scenarios: Real-world Advantages of Anti-Glare Etched Glass

- Petrochemical: Control room windows, hazardous area panel covers—resistant to acid fumes, fogging, and dust, allows 24/7 monitoring.

- Metallurgy: Viewing ports in high-heat, high-dust furnace areas, maintaining operator safety and visibility.

- Municipal Water & Power: Touch kiosks, status panels in humid, corrosive, or sunlight-exposed pump stations and substation yards.

- Medical & Diagnostics: Laboratory device screens, microscope panels, giving crystal-clear, glare-free viewing for hours.

- Industrial Displays: Embedded sensors, HMI interfaces, or ruggedized computers in food, pharma, and heavy industries.

- Banks & Public Facilities: ATM and self-service touchscreens for robust anti-vandalism and readability under direct sunlight.

- Public Transit: Ticketing machines, platform digital signage with anti-fingerprint coatings and low reflection for all-weather clarity.

- Industry Feedback: According to Glassonweb, end-users report field failures drop from 7% (standard AR) to under 1% using premium etched/AR hybrid glass, mainly due to better scratch and chemical resistance.

Case Study: Petrochemical Control Room – Reducing Downtime with Premium Anti Glare Etched Glass

Problem: Old acrylic and regular AR panel covers fogged, scratched, or yellowed within 8–12 months, leading to costly production halts.

Solution: Replaced over 120 control room and field instrument display covers with premium anti glare etched glass. Customized sizes fitted via CNC, with double-sided AR/nano-etch surface and sealed gasket installation.

Results (12 months):

- Zero field failures, no incidents of glare-based reading errors

- Maintenance intervals extended from 9 months to >3 years

- Visual contrast and color accuracy improved per EN ISO 9241-302 ergonomic standard

Certifications & Quality Assurance

- ISO 9001:2015 quality management system certified

- ANSI Z97.1 & ISO 9211 optical and safety glazing conformance

- RoHS/REACH/FDA chemical and environmental safety approvals

- Quality control: Surface, visual, haze, VLT, microstructure, and coating adhesion tests on every lot

- Trusted by leading OEMs: Tier-1 electronics brands, global medical suppliers, industrial automation system integrators

Delivery, Warranty and Customer Support

- Production lead time: Standard parts: 7–15 days; Custom CNC shapes: 15–25 days

- Shipping: Global shipping via crate/air-freight, sea-freight with damage insurance

- Warranty: Up to 10 years against delamination and surface defect (conditional on installation)

- After-sales: Technical and installation support, free replacement for verified manufacturing defects

- Customer care: Responsive in English, Spanish, Mandarin; 24hr support for mission-critical industries

Expert FAQ on Premium Anti Glare Etched Glass

What base materials are used in premium anti glare etched glass production?

Our premium anti glare etched glass is primarily manufactured from low-iron ultra-clear float glass and borosilicate glass to maximize clarity, impact resistance, and thermal stability.

What thicknesses and tolerances are supported?

Thickness options range from 1.1mm to 19mm, with common industry tolerances of ±0.15mm. CNC custom cuts can achieve complex outlines for precise panel fitting.

What is the recommended installation and mounting standard?

Installation should follow ISO 16283/EN 12758. Ensure clean, dry mounting environments with silicone-free gaskets; avoid organic adhesives that could deteriorate under UV exposure.

What tests verify optical performance and durability?

All batches undergo ISO 9050 (VLT/UV test), ASTM E903 (solar reflectance), ISO 9211 (coating adhesion), and ISO 15184 (scratch hardness). Salt-spray and humidity cycling ensure corrosion resistance.

Is the anti-glare property affected by cleaning or field abrasion?

No. The etched microstructure is part of the glass, not a wipe-on layer. Clean with non-abrasive solvents; the fogged or anti-glare surface will not degrade in regular use.

Can premium anti glare etched glass be used outdoors?

Absolutely. The material is weatherproof, UV stable, and corrosion resistant. Double-sided AR/etch is optimal for outdoor kiosks, signage, and public display hardware.

What product warranties and technical supports are provided?

All standard and custom products include a written warranty (up to 10 years). Technical engineers support pre- and post-sales, including installation assistance and after-sales service.

Contact our technical sales team for instant engineering support and free samples!

Get a Quote!

References & Industry Resources

- MarketsandMarkets. “Anti-Reflective Coatings Market by Application & Region - Global Forecast to 2028.” Link

- PRNewswire. “Anti-Reflective Glass Market Growth Global Insights and Forecast, 2022-2027.” Link

- Glassonweb. “Anti Glare Glass: How It’s Made, Applications & Market Insight.” Link

- Go. Al, K. et al. “Advances in anti-reflective and anti-glare glass surfaces.” Journal of Non-Crystalline Solids, 2022, 591. Link

- International Standards Organization. “ISO 9211: Optics and Optical Instruments - Optical Coatings.” Link

-

Chemically Strengthened Glass vs Tempered Glass

NewsJul.18,2025

-

Custom Frosted Glass Applications

NewsJul.18,2025

-

What’s the Difference Between Obscure Glass and Frosted Glass?

NewsJul.18,2025

-

Bullet Resistant Glass Levels

NewsJul.18,2025

-

Silver Wall Mirrors for Living Room

NewsJul.18,2025

-

Bullet Resistant Glass Definition

NewsJul.18,2025

Related PRODUCTS