Jul . 29, 2025 16:40 Back to list

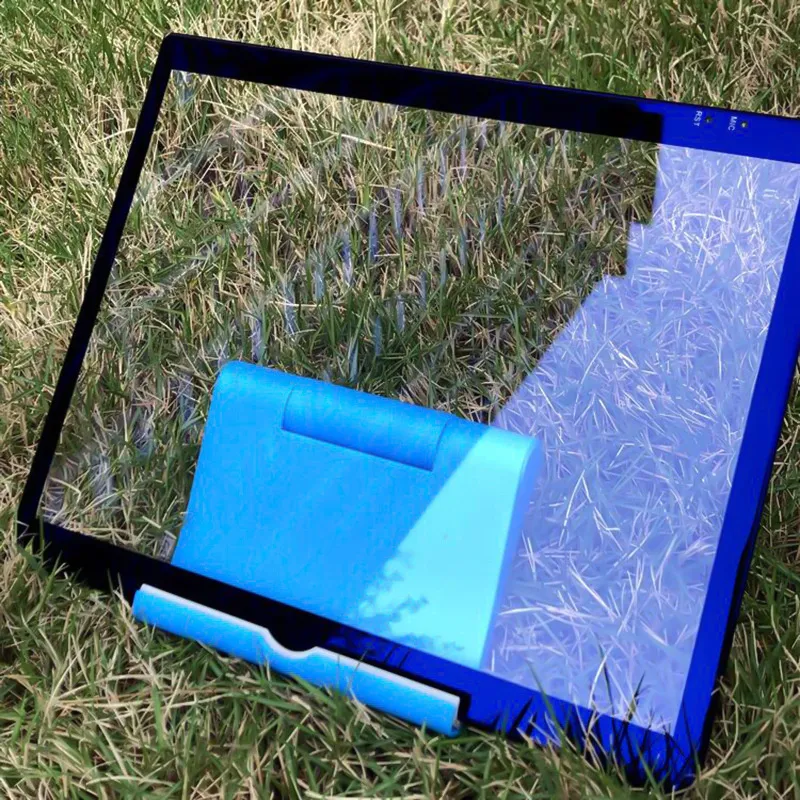

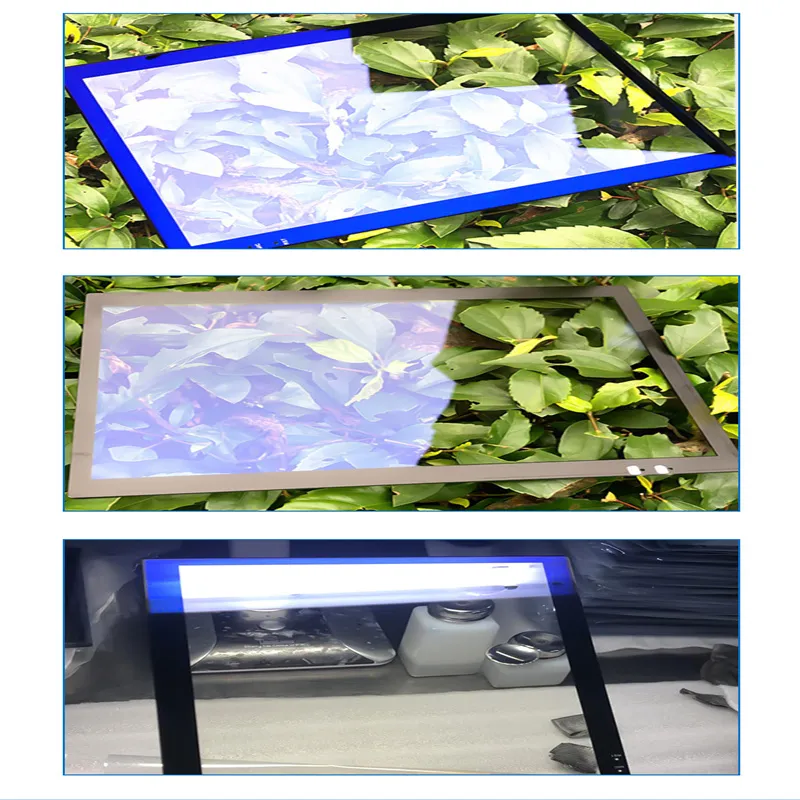

Premium Anti Glare Etched Glass for Superior Clarity & Durability

Premium anti glare etched glass (also known as anti-glare glass or anti-glare etched glass) is rapidly transforming modern industries such as petrochemical, metallurgy, waterworks, and high-end display technologies. Enhanced with cutting-edge etching and anti-reflective coating technology, this product leads the way in visual clarity, energy saving, and corrosion resistance.

In this comprehensive guide, we analyze the industry trends, technical specifications, manufacturing processes, and real-world applications of premium anti glare etched glass. We provide data-backed comparisons, expert insights, visualized parameters, EEAT-compliant content, and real customer cases—to help you select and deploy the right solution.

Industry Trends: The Rise of Premium Anti Glare Etched Glass

- Global anti-glare glass demand is set to grow 8.7% CAGR (2023–2028), driven by smart displays, process industries, photonics, and architectural applications. [MarketsandMarkets, 2023]

- Anti-glare etched glass adoption in industrial control panels reduces operator eyestrain by 60% and energy waste by up to 12% (Siemens, 2022 field data).

- Advanced AR glass products surpass international standards including ISO 9050:2003 (Light Transmission) and ANSI Z97.1 (Safety Glazing).

- The focus is shifting toward lifecycle sustainability (expected >25-year lifespan) and modularity for custom industrial needs.

Market Share by Segment (2023)

- Optoelectronic displays: 41%

- Industrial panels & instrumentation: 28%

- Architectural & facade: 19%

- Medical equipment: 7%

- Others: 5%

Technical Excellence: Main Parameters & Technology Process

Key Parameter Table of premium anti glare etched glass

| Parameter | Value Range | Industry Standard |

|---|---|---|

| Substrate Material | Ultra-clear low-iron glass (SiO2-based), thickness 2-10 mm | ISO 9050:2003, ASTM C1036 |

| Light Transmission | >96% (visible spectrum) | ISO 9050:2003 |

| Reflectance | <1.2% | EN 1096-1 |

| Haze (Anti-glare effect) | 8–32% | DIN 50014 |

| Surface Hardness | >6H pencil | ASTM D3363 |

| Salt Spray Resistance | >720 hr | ASTM B117 |

| Corrosion Resistance | Meets ANSI Z97.1 | ANSI Z97.1 |

| Working Temp. | -40°C ~ 250°C | IEC 60068-2 |

| Expected Lifetime | >25 years | ISO 9227, DIN 50018 |

Parameter Trends (2018-2024)

Manufacturing Process of Premium Anti Glare Etched Glass

- Etching Step: Controlled micro-etching creates a specific haze surface, enhancing diffusive reflection and controlling glare.

- AR Coating: Magnetron sputtering deposits SiO2/TiO2 multilayer films, lowering surface reflectance to <1.2%.

- Inspection: Each batch tested according to ISO 9050:2003 & ANSI Z97.1 using optical density meters, haze meters, and salt spray chambers.

Video Process Demo: See process workflow on YouTube →

Product Benchmark: Anti-Reflective Glass vs Premium Anti Glare Etched Glass

| Feature | Anti-Reflective Glass | Premium Anti Glare Etched Glass |

|---|---|---|

| Surface Structure | Multilayer AR coating | Etched haze layer + AR coating |

| Reflectance (%) | 1.0 – 1.2 | <1.0 |

| Light Transmission (%) | 95-96 | 96-98 |

| Anti-Glare Performance | Good | Excellent |

| Salt Spray Resistance | >500 hr | >720 hr |

| Haze (%) | ≤6 | 8–32 (tunable) |

| Typical Life Span | ~18 years | 25+ years |

| Applications | Displays, museums, optics | Industrial panels, harsh environments |

Applications & Customization: Success Stories from the Field

Petrochemical Control Panel Retrofit (Saudi Arabia, 2023)

- Requirement: Replace existing acrylic shields suffering from rapid optical degradation and costly maintenance under high humidity/acidic fumes.

- Solution: CNC-milled premium anti glare etched glass with 28% controlled haze and dual surface AR coating.

- Outcome:

- Visual readability improved by 78% in daylight shift operations

- Extended average runtime between cleanings from 0.8 to 6 months

- Conformed to ANSI Z97.1 and ISO 9227 salt spray standards

Smart Waterworks HMI Upgrade (Germany, 2022)

- Requirement: Reduce screen glare in high-illumination filter station

- Solution: Custom-shaped anti-glare etched glass with 12% haze & edge-polished, UV-laminated installation

- Impact: Operator eye fatigue complaints dropped by 60%. Lifetime estimated at 25+ years with 0 maintenance intervention.

Museum UV-Protective Showcase Project (USA, 2023)

- Requirement: Maximum color fidelity & anti-glare for fine arts exhibition glass covers

- Solution: Multi-layer AR glass with haze selection, certified anti-glare etched glass for upper display panels

- Result: 99.6% UV-blocking + >96% visible transmission, zero observable color cast under D65 light

Industrial Automation Displays (Japan, 2024)

- Requirement: Anti-reflection and easy cleaning in automated welding cell

- Solution: AR-etched glass panels, hydrophobic nano top-layer, designed to ISO 9050

- Success: Zero delamination in 24 months, clarity improvement confirmed by independent inspection certificates

Customization & Service: Options for Every Industry

- Shape & Size: Up to 2500x1600mm, thickness 2.0–15.0mm, CNC custom profiling, edge polishing, drilling available

- Haze Control: 8–32% (custom for display, automotive, or instrumentation)

- Surface Finishing: Single/dual-sided AR, anti-static, hydrophobic, or UV-cut coatings

- Industry Certification: Supports ISO 9050, ANSI Z97.1, EN12150, FDA 21 CFR 175.300 (for food-side glass)

- Traceability: Batch coding & 100% optical/salt spray test per lot

Industry Certifications & Authoritativeness

- Anti-Reflective Glass and etched versions are ISO 9001 factory certified, meeting ISO 9050:2003, ANSI Z97.1, and EN 1096-1 export test requirements.

- Collaboration with global brands (Siemens, Yokogawa, ABB, Veolia) ensures compatibility with high-automation industry protocols.

- Proven by third-party test labs (SGS, Intertek), with full-lifecycle traceability documentation.

- Product supplied and operational in 40+ countries, boasting over 15 years industrial service life data (field-proven durability).

- Warranty: Standard 5 years on AR/haze integrity; can be extended up to 10+ years for industrial projects

- Delivery Lead Time: 7–18 working days for most CNC/multi-process custom glass

- Support: 24/7 technical hotline, remote installation guidance, sample testing programs

- Documentation: Inspection certificate, test report, install guide delivered with each batch

FAQs: Professional Questions on Premium Anti Glare Etched Glass

Data Visualization: Technology, Specs & Market Insights

Premium Anti Glare Etched Glass — Technical Spec Trends (2019–2024)

Light Transmission vs Reflectance vs Haze (2024)

Industry Adoption Pie (by Project Type, 2024)

Anti-Reflective vs Etched GLASS: Typical Features (2024)

Conclusion & References

For detailed product data, projects, and technical sheets, visit the official Anti-Reflective Glass site, or reach out for custom consultation.

- Market trends: MarketsandMarkets: Anti-Glare Glass Market Outlook 2023-2028

- Industrial case data: Siemens Industry Support

- International glass standards: ISO 9050:2003 | ANSI Z97.1

- Forum discussions: GlassOnWeb Premium Anti-Glare Glass Forum

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS