Sep . 09, 2025 22:00 Back to list

Premium Anti-Glare Etched Glass | Superior Clarity & Durability

The Imperative of High-Performance Anti-Glare Etched Glass in Modern Displays

In an era defined by ubiquitous digital interfaces, the demand for superior visual clarity and user experience has never been higher. Across industrial, commercial, and consumer sectors, display performance is paramount, especially in environments prone to harsh lighting conditions. This necessitates advanced solutions that mitigate reflections without compromising optical integrity. One such cornerstone technology is premium anti glare etched glass, a specialized substrate engineered to diffuse incident light, thereby eliminating distracting glare and enhancing readability. Unlike conventional coated alternatives, etched glass offers a robust, permanent solution, making it ideal for critical applications where durability and consistent performance are non-negotiable.

The market trend unequivocally points towards increasing adoption of high-performance anti-glare solutions. As industrial control panels migrate from traditional button-based interfaces to sophisticated touchscreens, and outdoor digital signage becomes more prevalent, the need for displays that remain legible under direct sunlight or intense artificial light sources grows exponentially. Manufacturers are increasingly prioritizing materials that offer both superior optical properties and exceptional environmental resilience. This article delves into the technical intricacies, application advantages, and comprehensive offerings surrounding premium anti-glare etched glass, providing B2B decision-makers and engineers with a profound understanding of its strategic value.

The Precision Manufacturing Process of Etched Anti-Glare Glass

The creation of premium anti glare etched glass is a multi-stage, precision-driven manufacturing process, ensuring consistent quality and optical performance. This process transforms standard float glass into a highly functional anti-glare substrate through carefully controlled chemical or mechanical treatments.

Detailed Process Flow:

- 1. Glass Material Selection: The foundation is high-quality float glass (typically soda-lime glass or borosilicate glass), chosen for its optical clarity, flatness, and absence of imperfections. The raw material supplier adherence to international standards like ASTM C1036 is critical.

- 2. Precision Cutting: Large glass sheets are cut to specified dimensions using advanced CNC machining, ensuring precise tolerances. This stage minimizes material waste and prepares the glass for subsequent treatments.

- 3. Edge Grinding and Polishing: Edges are ground and polished to remove sharp points and reduce stress concentrations, enhancing the glass's overall strength and safety.

-

4. Etching Process (Chemical or Mechanical):

- Acid Etching: The most common method, where glass is immersed in a controlled chemical bath (typically hydrofluoric acid solution). This process selectively removes microscopic layers of glass, creating a uniformly roughened surface with specific haze and gloss characteristics. Precise control over acid concentration, temperature, and immersion time is crucial to achieve desired anti-glare properties.

- Mechanical Etching (Sandblasting/Micro-blasting): While less common for fine anti-glare finishes, this involves propelling abrasive particles at the glass surface to create a textured finish. More suitable for coarser textures or specific industrial applications.

- 5. Cleaning and Neutralization: After etching, the glass undergoes thorough cleaning and neutralization to remove any chemical residues and ensure a pristine surface. This is critical for preventing long-term degradation and for subsequent processing steps.

- 6. Optional Tempering: For enhanced strength and safety, the etched glass can undergo thermal tempering. This involves heating the glass to a high temperature (around 700°C) and then rapidly cooling it, creating compressive stress on the surface and making it significantly more resistant to breakage (often 3-5 times stronger than annealed glass). This process adheres to standards such as ANSI Z97.1 and EN 12150.

- 7. Quality Control and Testing: Each batch undergoes rigorous testing to ensure it meets specified optical and mechanical properties. This includes haze and gloss measurement (e.g., ASTM D1003), light transmission, reflection, scratch resistance, and often chemical resistance tests. Adherence to ISO 9001 quality management systems is standard.

- 8. Packaging and Shipment: Finished glass is carefully packaged to prevent damage during transit, using specialized interlayers and robust crating.

The result is an anti-glare etched glass product with an impressive service life, often exceeding 10-15 years in typical industrial environments, due to the inherent durability of the etched surface which does not degrade or peel like coatings. This makes it an energy-saving choice by reducing the need for excessively bright backlights and provides superior corrosion resistance compared to many coated alternatives.

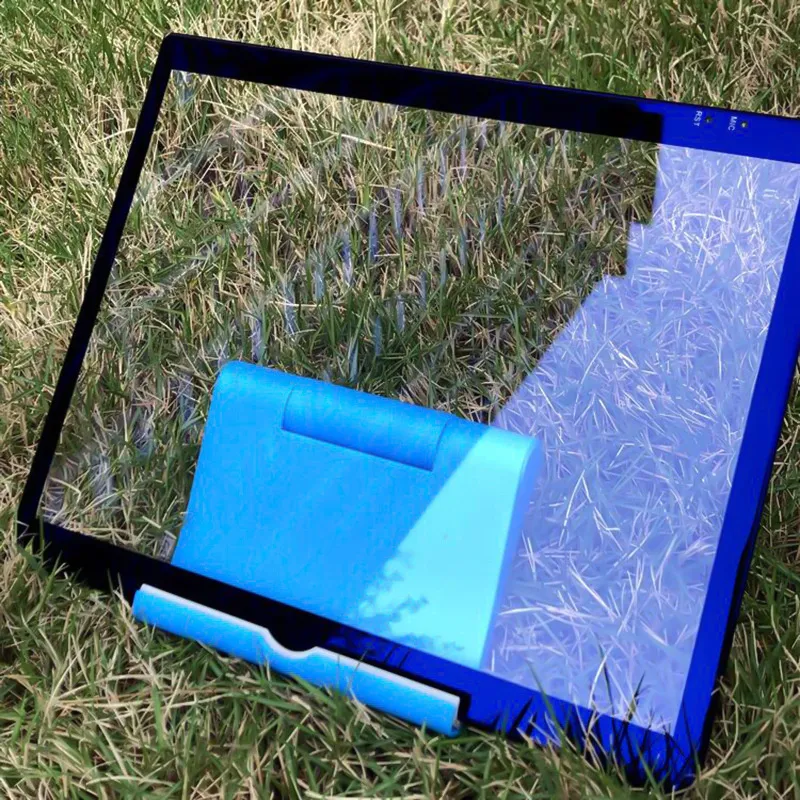

Advanced etching processes ensure consistent glare reduction.

Technical Specifications and Performance Parameters of Premium Anti-Glare Etched Glass

Understanding the precise technical parameters of anti-glare glass is crucial for engineers and product managers to select the optimal solution for their specific application. The performance of premium anti glare etched glass is quantified by several key metrics that define its optical and mechanical characteristics.

Key Optical and Mechanical Parameters:

- • Haze Value (ASTM D1003): Measures the percentage of transmitted light that is scattered more than 2.5 degrees from the incident light direction. A higher haze value indicates a more diffused surface and greater glare reduction. Typical range for anti-glare etched glass is 5% to 90%, with industrial applications often favoring 15-30% for a balance of glare reduction and clarity.

- • Gloss Level (ASTM D523): Measures the specular reflectance of the surface at specific angles (e.g., 60°, 85°). Lower gloss values correspond to a more matte finish and less mirror-like reflection. Standard industrial glass typically has gloss values below 10-20 GU (Gloss Units) at 60°.

- • Light Transmission: The percentage of incident light that passes through the glass. High transmission (typically >90%) is desired to maintain display brightness and color fidelity.

- • Reflectance (Specular/Diffuse): Measures the amount of light reflected from the surface. Anti-glare treatments significantly reduce specular reflection.

- • Surface Hardness (Mohs/Pencil Hardness): Indicates resistance to scratching. Glass typically rates 5-6 on the Mohs scale. Etching does not significantly alter this inherent hardness, offering superior scratch resistance compared to most polymer-based anti-glare films.

- • Chemical Resistance: Etched glass maintains the excellent chemical resistance of its base glass, making it suitable for environments where exposure to cleaning agents or corrosive substances is common (e.g., medical, industrial).

- • Impact Resistance: When thermally tempered, etched glass meets stringent impact resistance standards, crucial for safety-critical applications (e.g., EN 12150-2, ANSI Z97.1).

Typical Product Specification Table: Premium Anti-Glare Etched Glass

These parameters, especially haze and gloss, are critical in determining the visual performance of the anti-glare etched glass in varied lighting conditions. A carefully chosen haze level ensures optimal readability without excessive image diffusion, maintaining the sharpness required for complex graphics and text.

Application Scenarios Across Diverse Industries

The versatility and robust performance of premium anti glare etched glass make it an indispensable component across a broad spectrum of industrial and commercial applications where display clarity and durability are paramount. Its unique properties address critical operational challenges, improving safety, efficiency, and user experience.

Target Industries and Advantages:

-

• Petrochemical and Oil & Gas:

Human-Machine Interface (HMI) panels and control room displays often operate in challenging, sometimes hazardous, environments. Anti-glare etched glass provides exceptional readability under varying artificial and natural light conditions, reducing operator eye strain and enhancing safety-critical decision-making. Its inherent corrosion resistance to many industrial chemicals also extends service life significantly.

-

• Metallurgy and Heavy Industry:

In foundries, steel mills, and heavy manufacturing plants, robust displays are crucial. Anti-glare glass protects against dust, sparks, and chemical splashes while ensuring clear visibility of process parameters, even under intense overhead lighting or ambient light from molten materials. The thermal stability of tempered etched glass is also highly beneficial.

-

• Water Supply & Drainage Systems:

Outdoor monitoring stations, pump control panels, and municipal utility interfaces require displays that are legible in direct sunlight and resistant to environmental degradation. Anti-glare etched glass offers unparalleled outdoor readability and protection against weather elements, contributing to reliable infrastructure management and reduced maintenance costs (energy saving from less need for brighter backlights).

-

• Medical and Healthcare:

Diagnostic equipment, patient monitors, and surgical displays demand pristine image quality and easy cleaning. Anti-glare etched glass surfaces are compatible with common disinfectants and resist smudging, ensuring hygiene and uncompromised visual data for critical medical procedures.

-

• Automotive and Avionics:

Cockpit displays, infotainment systems, and dashboard instruments require glare-free visibility for driver/pilot safety. Etched glass provides a durable solution that withstands extreme temperatures and vibrations while ensuring clear information display, even in challenging lighting conditions.

-

• Public Kiosks and Digital Signage:

Outdoor and semi-outdoor interactive displays in retail, transportation, and entertainment benefit immensely from etched anti-glare glass. It ensures messages are visible and interactive elements are responsive, even under direct sunlight, thereby maximizing engagement and effectiveness.

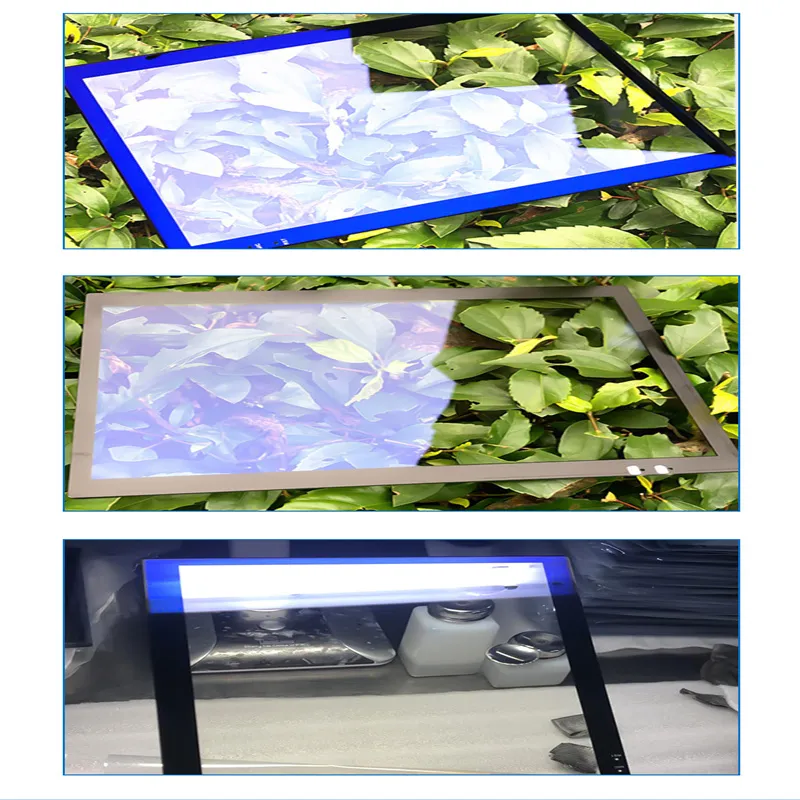

Enhanced visibility for industrial control panels.

Unpacking the Technical Advantages of Etched Anti-Glare Glass

The choice between different anti-glare technologies often comes down to long-term performance, durability, and cost of ownership. Premium anti glare etched glass consistently outperforms many alternatives, especially coated solutions, due to its fundamental physical modification of the glass surface.

Key Advantages Over Coated Alternatives:

- • Unparalleled Durability: Unlike anti-glare coatings, which are applied layers that can scratch, peel, or delaminate over time, etching is an integral part of the glass itself. This permanent alteration ensures that the anti-glare properties will last the lifetime of the glass, even in high-traffic or harsh industrial environments. This reduces replacement costs and maintenance.

- • Consistent Optical Performance: The etched surface provides a uniform diffusion of light, offering consistent anti-glare performance across the entire display area and over time. Coatings can exhibit variations in thickness or degrade unevenly, leading to inconsistent glare reduction.

- • Superior Scratch and Abrasion Resistance: The hardness of the glass remains largely unaffected by the etching process. This means anti-glare etched glass is far more resistant to scratches and abrasions than soft film coatings, which are easily damaged, especially on touchscreens or public displays.

- • Enhanced Chemical Resistance: Etched glass retains the high chemical resistance of its original substrate, making it impervious to many common cleaning agents, solvents, and industrial chemicals that might degrade or damage anti-glare films or coatings. This is crucial for medical devices and industrial panels requiring frequent sterilization or cleaning.

- • Improved Sunlight Readability and Reduced Eye Fatigue: By diffusing specular reflections, anti-glare etched glass drastically improves readability under direct sunlight or intense indoor lighting. This not only enhances user experience but also significantly reduces eye strain for operators and users who interact with displays for extended periods, contributing to better ergonomics and productivity.

- • Broad Temperature Stability: As a solid glass material, etched glass can withstand wider temperature fluctuations than polymer-based films, making it suitable for extreme industrial or outdoor environments without risk of degradation or delamination.

- • Compatibility with Touchscreen Technology: The precisely controlled surface texture of premium etched glass allows for smooth finger gliding for touch applications, often providing a more natural and responsive feel compared to other anti-glare methods, without interfering with touch sensor sensitivity.

These advantages collectively underscore why premium anti glare etched glass is the preferred choice for critical B2B applications demanding longevity, reliability, and superior optical performance under challenging conditions.

Vendor Comparison and Selection Criteria for Anti-Glare Glass Suppliers

Choosing the right supplier for premium anti glare etched glass is a critical decision that impacts product quality, project timelines, and overall cost-effectiveness. A thorough evaluation based on key criteria is essential for B2B procurement and engineering teams.

Key Factors for Supplier Selection:

- • Quality Control and Certifications: Look for suppliers with robust ISO 9001 certified quality management systems. Additional industry-specific certifications (e.g., IATF 16949 for automotive, ISO 13485 for medical) are strong indicators of adherence to stringent quality standards.

- • Customization Capabilities: The ability to produce glass with specific haze levels, dimensions, thicknesses, and additional features (e.g., optical bonding, anti-fingerprint coatings) is crucial for specialized applications.

- • Technical Support and R&D: A supplier with strong in-house technical expertise can provide valuable guidance on material selection, design optimization, and troubleshooting, accelerating product development cycles. Their commitment to R&D signifies continuous product improvement.

- • Track Record and Partner Clients: Evaluate the supplier's experience, years in service, and a portfolio of reputable clients. Case studies and testimonials offer insights into their reliability and capability to deliver complex projects.

- • Lead Time and Supply Chain Reliability: Assess their manufacturing capacity, inventory management, and logistics capabilities to ensure on-time delivery, especially for high-volume orders or just-in-time production requirements.

- • Cost-Effectiveness vs. Value: While price is a factor, prioritize the overall value proposition, considering product longevity, performance, and the cost savings from reduced maintenance and improved user experience.

Comparative Analysis: Anti-Glare Glass Suppliers (Illustrative)

This comparative framework assists in aligning a supplier's capabilities with specific project requirements, ensuring a strategic partnership for long-term success in implementing anti-glare etched glass solutions.

Rigorous testing ensures compliance with industry standards.

Tailored Solutions: Customization for Unique Demands

While standard anti-glare etched glass products offer significant advantages, many B2B applications have highly specific requirements that necessitate customized solutions. Leading manufacturers excel in collaborating with clients to develop tailored anti-glare glass that perfectly integrates with their unique product designs and operational environments.

Key Customization Options:

- • Custom Dimensions and Shapes: Beyond standard rectangular cuts, suppliers can produce glass in intricate shapes, with precise cutouts, holes, and edge finishes (e.g., polished, beveled) to fit complex enclosure designs.

- • Specific Haze and Gloss Levels: The etching process can be finely controlled to achieve a wide range of haze values (e.g., from 5% for minimal diffusion to 50%+ for aggressive glare reduction) and corresponding gloss levels, optimizing visual clarity for specific display types and ambient light conditions.

- • Thickness and Substrate Material: Glass thickness can be customized from ultra-thin (e.g., 0.7mm for portable devices) to robust (e.g., 6mm+ for public kiosks). Different glass types, such as borosilicate for higher thermal shock resistance or specialized low-iron glass for enhanced clarity, can also be used.

-

• Additional Coatings and Treatments:

- Anti-Reflective (AR) Coatings: While etched glass reduces glare, a separate AR coating can be applied to the non-etched side to further reduce internal reflections and enhance light transmission, creating a truly superior optical solution.

- Anti-Fingerprint (AF) / Hydrophobic Coatings: Applied to the etched surface, these oleophobic coatings repel oils and water, making the glass easier to clean and maintaining a clear view, especially for touchscreens.

- Anti-Microbial Coatings: Essential for medical and public interfaces, these coatings inhibit bacterial growth.

- • Optical Bonding: For outdoor and ruggedized displays, optical bonding of the anti-glare etched glass directly to the display panel eliminates air gaps, reducing internal reflections, improving sunlight readability, and enhancing impact resistance.

- • Integrated Features: Custom silkscreen printing (e.g., company logos, bezels, functional indicators) can be integrated into the glass, offering aesthetic and functional enhancements.

The ability to provide these comprehensive customization options ensures that the final premium anti glare etched glass product is not just a component, but an integral, optimized part of the overall system, delivering maximum performance and value. Collaborative design and engineering support are hallmarks of a superior supplier in this niche.

Real-World Applications and Case Studies

The tangible benefits of premium anti glare etched glass are best illustrated through real-world applications where its properties have solved critical display challenges and enhanced operational efficiency. These case studies highlight its practical value in demanding environments.

Case Study 1: Enhanced HMI Visibility in a Major Refinery

- • Client: A leading international petrochemical company.

- • Challenge: Operators in the refinery's control room struggled with severe glare on their HMI touchscreens due to numerous overhead lights and large windows. This led to eye fatigue, reduced operational efficiency, and potential safety risks from misreading critical data.

- • Solution: The existing HMI protective covers were replaced with custom-cut, thermally tempered anti-glare etched glass (15% haze, 60° gloss of 8 GU). The glass was also treated with an oleophobic coating for easy cleaning.

- • Outcome: Operators reported a dramatic reduction in glare (estimated 80% subjective improvement) and significantly decreased eye strain. The clarity of the displays improved, leading to faster data interpretation and a measurable increase in operational accuracy. The durable etched surface also provided long-term resistance to chemical cleaning agents.

Case Study 2: Rugged Outdoor Kiosks for Public Transportation

- • Client: A municipal transportation authority deploying self-service ticketing kiosks at bus stops and train stations.

- • Challenge: The original kiosks used standard glass, rendering the touchscreens almost unreadable under direct sunlight or bright ambient conditions, frustrating users and leading to service complaints. The glass also needed to withstand vandalism and varying weather.

- • Solution: Robust, optically bonded 6mm thick anti-glare etched glass (30% haze) was integrated. The glass was specifically selected for high impact resistance (meeting ANSI Z97.1) and enhanced outdoor readability.

- • Outcome: The new displays offered crystal-clear visibility in all lighting conditions, dramatically improving user satisfaction and reducing support calls. The exceptional durability of the etched glass reduced instances of damage from vandalism, leading to significant cost savings in maintenance and replacement over a projected 10-year service life.

Anti-glare solutions for diverse display applications.

Ensuring Trust: FAQ, Support, and Warranties

Building trust with B2B clients extends beyond product performance to transparent communication, reliable support, and clear commitments. This section addresses common inquiries, outlines logistical details, and details warranty provisions for premium anti glare etched glass.

Frequently Asked Questions (FAQ):

A: Etched anti-glare glass achieves its effect through a permanent physical alteration of the glass surface, making it extremely durable and resistant to wear, scratches, and chemicals. Coated anti-glare glass relies on an applied layer, which can be susceptible to peeling, delamination, or degradation over time, especially in harsh environments. Etched glass offers superior longevity and consistent performance.

A: Yes, our anti-glare etched glass can be fully tempered after the etching process, significantly increasing its mechanical strength and making it a safety glass (shattering into small, blunt pieces upon breakage). This adheres to international safety standards like ANSI Z97.1 and EN 12150.

A: Due to its robust surface, etched glass can be cleaned with standard glass cleaners or mild detergents and a soft, lint-free cloth. Avoid abrasive materials or harsh chemicals that could potentially scratch or alter the optical properties of the surface over time. For best results, follow specific cleaning guidelines provided by the manufacturer.

A: Absolutely. Our etched glass can be combined with additional features such as anti-reflective (AR) coatings on the opposite side for ultra-low reflection, anti-fingerprint (AF) coatings for easy maintenance, or even integrated touch sensor layers and optical bonding for enhanced display performance in challenging applications.

Lead Time & Fulfillment Details:

- • Standard Products: For common dimensions and haze levels, lead times typically range from 2-4 weeks.

- • Custom Orders: Complex custom orders (unique shapes, specific haze/gloss values, additional coatings, tempering) generally require 4-7 weeks, depending on complexity and volume.

- • Production Capacity: Our state-of-the-art facilities ensure high-volume production capabilities, meeting demands for large-scale industrial projects while maintaining precision and quality.

- • Logistics: We offer flexible shipping options, including sea, air, and expedited freight, with robust packaging designed to protect sensitive glass products during transit globally.

Warranty Commitments:

We stand behind the quality and durability of our premium anti glare etched glass products. All products come with a standard 12-month limited warranty against manufacturing defects. Extended warranty options are available for specific project requirements. Our warranty covers material and workmanship, ensuring that the optical and mechanical properties meet the agreed-upon specifications and industry standards for the warranted period. Full warranty terms and conditions are available upon request.

Customer Support:

Our dedicated customer support and technical assistance teams are available to provide expert guidance throughout the entire project lifecycle, from initial concept and design consultation to post-installation support. We offer:

- • Technical Consultation: Assistance with material selection, optical performance optimization, and integration challenges.

- • Sample Provision: Providing samples for testing and evaluation prior to mass production.

- • After-Sales Service: Prompt response to any product-related queries or issues post-delivery.

- • Contact Information: For inquiries, please reach out via our website's contact form or directly through the provided sales and technical support channels.

Conclusion

In summary, premium anti glare etched glass represents a critical advancement in display technology for B2B applications. Its inherent durability, superior optical performance, and resistance to environmental factors far surpass those of conventional anti-glare films or coatings. From the meticulous manufacturing process, incorporating precise etching and rigorous quality control, to its versatile application across petrochemical, metallurgy, medical, and public interface sectors, etched glass delivers tangible benefits in terms of enhanced readability, reduced eye strain, and extended product lifespan. As industries continue to embrace digital transformation and demand robust, high-performance visual interfaces, the strategic adoption of tailored anti-glare etched glass solutions will be paramount for ensuring operational excellence and a competitive edge. Investing in this advanced glass technology is not merely a component choice; it is an investment in long-term reliability, user satisfaction, and overall system performance.

References

- American Society for Testing and Materials (ASTM) D1003-13, "Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics," ASTM International.

- International Organization for Standardization (ISO) 9001:2015, "Quality management systems — Requirements," ISO.

- American National Standards Institute (ANSI) Z97.1-2015, "Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test," ANSI.

- International Electrotechnical Commission (IEC) 60068-2-1/2, "Environmental testing – Part 2: Tests – Test A: Cold / Test B: Dry heat," IEC.

- Oh, S. H., & Kim, M. G. (2018). "Optical properties of anti-glare glass fabricated by chemical etching for display applications." Journal of the Korean Ceramic Society, 55(4), 384-391.

- Sakamoto, W., & Yoko, T. (2019). "Recent advances in sol-gel derived anti-reflective and anti-glare coatings." Progress in Organic Coatings, 133, 1-14.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS