Aug . 12, 2025 03:00 Back to list

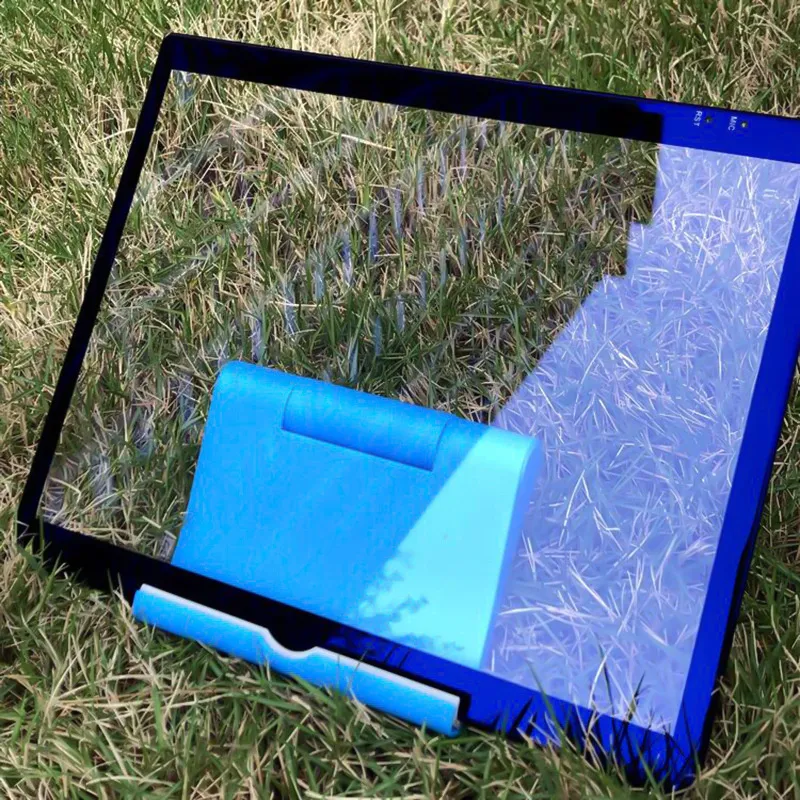

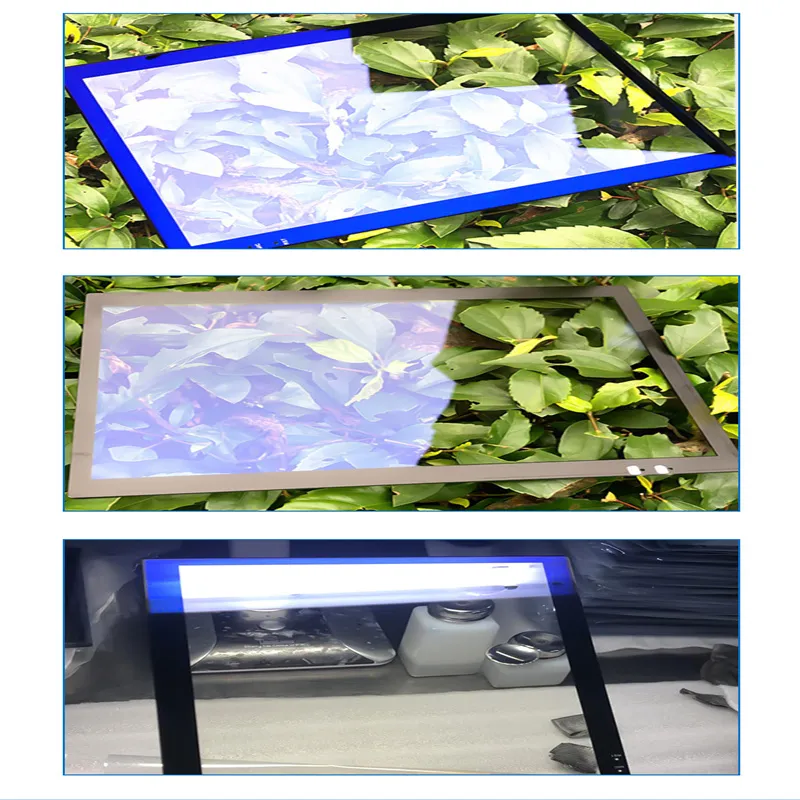

Premium Anti-Glare Etched Glass: Ultimate Clarity, Glare-Free

Navigating the Landscape of Advanced Display Solutions: The Rise of Anti-Glare Etched Glass

In an era dominated by digital interfaces, the quality of visual display has become paramount across diverse industries, from automotive and medical to industrial control and consumer electronics. A critical challenge frequently encountered is glare, which can significantly diminish user experience, reduce readability, and even pose safety risks in high-stakes environments. Addressing this, premium anti glare etched glass stands out as a superior solution, meticulously engineered to diffuse reflected light and enhance visual clarity. This specialized glass is transforming how users interact with screens, providing unparalleled visibility under varying lighting conditions. The market for advanced display solutions, particularly those incorporating sophisticated anti-glare properties, is experiencing robust growth, driven by an increasing demand for intuitive and highly functional human-machine interfaces (HMIs) and touchscreens that perform optimally even in challenging ambient light. Recent industry reports indicate that the global anti-glare display market is projected to reach over $7 billion by 2027, demonstrating a compound annual growth rate (CAGR) of approximately 6-8%, fueled by innovations in display technology and expanding application fields.

Beyond mere aesthetics, the integration of premium anti glare etched glass directly impacts operational efficiency and user comfort. In environments like medical operating rooms, industrial control panels, or outdoor kiosks, accurate and immediate information processing is vital. Glare-induced visual fatigue or misinterpretation of data can lead to costly errors or safety hazards. Therefore, the strategic adoption of anti-glare solutions is not just an upgrade but a necessity for critical applications. This article delves into the intricate details of this specialized glass, exploring its manufacturing processes, technical specifications, diverse applications, and the distinct advantages it offers in a competitive technological landscape.

The Science and Specification of Anti-Glare Etched Glass

The efficacy of premium anti glare etched glass lies in its precisely engineered surface. Unlike coatings, which can scratch or peel, etching creates a permanent, microscopic texture on the glass surface. This texture scatters incoming light rather than reflecting it directly, thereby minimizing glare. The primary methods for achieving this include chemical etching, where acid baths meticulously dissolve glass to create a consistent roughened surface, or mechanical etching, which involves physical abrasion. Chemical etching is widely preferred for its ability to produce highly uniform and fine textures, offering precise control over critical optical parameters.

Key performance indicators for anti-glare etched glass include Haze, Gloss, and Light Transmission. Haze refers to the percentage of transmitted light that is scattered by the sample, indicating the degree of diffusion. A higher haze value typically correlates with greater anti-glare performance. Gloss, measured in gloss units (GU) at specific angles (e.g., 60 degrees), quantifies the specular reflectance – how shiny the surface appears. Lower gloss values signify less direct reflection. Light transmission, the percentage of light passing through the glass, is crucial for maintaining display brightness and color fidelity. Optimal anti-glare glass balances these parameters to provide superior readability without compromising visual quality. For instance, a typical premium anti-glare etched glass might feature a haze value of 8-20% and a gloss value of 60 GU or less, ensuring excellent glare reduction.

Below is a typical specification table for premium anti glare etched glass:

| Parameter | Description | Typical Range (Premium Grade) | Measurement Standard |

|---|---|---|---|

| Haze Value | Percentage of transmitted light scattered from the main beam. | 5% - 20% (Adjustable) | ASTM D1003 |

| Gloss Level (60°) | Specular reflection property of the surface. | 60 GU and below (Adjustable) | ASTM D523 |

| Light Transmission | Percentage of incident light passing through the material. | > 90% | ASTM D1003 |

| Reflection Rate | Percentage of incident light reflected from the surface. | < 1% (single side) | ASTM E1347 |

| Surface Hardness | Resistance to scratching. | > 6H (Mohs) | Pencil Hardness Test |

| Glass Substrate | Type of base glass used. | Soda-lime, Borosilicate, Corning Gorilla Glass, etc. | Material Certification |

Detailed Manufacturing Process & Quality Assurance

The production of high-quality anti-glare etched glass involves a meticulous multi-stage manufacturing process, ensuring both optical precision and structural integrity. This process typically begins with the selection of premium glass substrates, such as soda-lime glass, borosilicate glass, or chemically strengthened glass (e.g., Corning Gorilla Glass, AGC Dragontrail), chosen for their specific mechanical and thermal properties relevant to the final application. The choice of material directly impacts the glass's durability, impact resistance, and thermal stability. For instance, chemically strengthened glass undergoes an ion-exchange process that enhances its surface compression, making it exceptionally resistant to scratches and impacts, a crucial factor for touch-sensitive displays.

The core of the manufacturing lies in the etching stage. For chemical etching, glass panels are first thoroughly cleaned to remove any contaminants. They are then immersed in a precisely formulated acid solution, typically hydrofluoric acid or a mixture, under controlled temperature and time parameters. This acid selectively dissolves the glass surface at a microscopic level, creating a finely textured, non-glare finish. Post-etching, the glass undergoes a series of neutralization and rinsing baths to ensure all chemical residues are completely removed, followed by advanced drying processes to prevent water spots or streaks. The consistency of the etching depth and pattern is critical for achieving uniform anti-glare performance across the entire surface.

Quality assurance is integral throughout the entire production lifecycle, adhering to stringent international standards such as ISO 9001 for quality management systems and ANSI standards for specific optical or safety requirements. Each batch of anti-glare etched glass undergoes rigorous inspection, including optical performance tests (haze, gloss, transmission), surface uniformity checks, visual defect inspections, and dimensional accuracy measurements. Durability tests, such as scratch resistance (e.g., Mohs hardness scale, pencil hardness test), abrasion resistance, and environmental stability tests (temperature and humidity cycling), are also routinely performed to ensure the glass maintains its performance and integrity over an extended lifespan, often exceeding 10-15 years in typical industrial or commercial applications. This comprehensive approach to manufacturing and quality control guarantees that the final product consistently meets the high expectations of B2B clients for reliability and performance.

Diverse Application Scenarios and Technical Advantages

The versatility of premium anti glare etched glass makes it an indispensable component across a wide array of industries, significantly enhancing the functionality and user experience of various digital displays and interfaces. In the automotive sector, it is crucial for dashboard displays, infotainment systems, and heads-up displays, where it minimizes sun glare and reflections from interior lighting, ensuring driver safety and clear readability of critical information. The glass's durability also withstands the harsh automotive environment, including temperature fluctuations and vibrations. Similarly, medical devices, ranging from surgical monitors to patient diagnostic screens, demand absolute clarity and minimal reflection for precise operation and accurate data interpretation. Anti-glare etched glass ensures sterile environments are maintained while providing crystal-clear images, which is vital for patient care and accurate diagnoses. Its anti-fingerprint properties also contribute to hygiene and ease of cleaning in clinical settings.

For industrial control systems and machinery, where human-machine interfaces (HMIs) are often located in brightly lit factories or outdoor settings, anti-glare glass provides robust protection and consistent visibility. This ensures operators can easily read data, control processes, and respond quickly, even under challenging lighting conditions. This directly translates to improved operational efficiency and reduced downtime. In retail and public kiosks, outdoor digital signage, and point-of-sale (POS) systems, the glass prevents washout from direct sunlight, maintaining vibrant display quality and ensuring messages are always visible and engaging to customers. Additionally, its inherent scratch resistance prolongs the lifespan of public-facing displays, reducing maintenance costs.

The technical advantages of etched glass over coated alternatives are significant. Etching creates a permanent, integral surface texture, making it far more durable and resistant to scratching, abrasion, and chemicals compared to applied coatings that can delaminate, wear off, or become damaged over time. This inherent robustness contributes to a longer product lifespan and lower total cost of ownership. Furthermore, the uniform diffusion of light reduces eye strain and fatigue, especially during prolonged use, a crucial ergonomic benefit for any interactive display. It also enhances contrast and color saturation by minimizing reflected light, leading to a more vibrant and accurate visual experience. This comprehensive suite of benefits positions anti-glare etched glass as the preferred choice for high-performance and high-reliability display applications.

Choosing the Right Partner: Manufacturer Capabilities and Custom Solutions

Selecting the right manufacturer for premium anti glare etched glass is a critical decision that profoundly impacts product performance, project timelines, and overall cost-efficiency. A reputable manufacturer differentiates itself through several key attributes, including extensive expertise in glass processing, advanced R&D capabilities, a proven track record of delivering high-quality products, and robust quality control systems that adhere to international standards like ISO 9001 and IATF 16949 (for automotive applications). Companies with decades of experience in optical glass solutions often possess proprietary etching technologies and a deep understanding of surface chemistry, enabling them to achieve precise control over haze and gloss levels tailored to specific application requirements. Furthermore, a strong engineering team is essential for collaborative design and problem-solving, ensuring that the glass solution integrates seamlessly into the client’s final product.

Customization is a cornerstone of B2B engagements for anti-glare etched glass. Manufacturers should offer comprehensive customization capabilities beyond standard sizes and thicknesses. This includes precise control over the etching process to achieve specific haze and gloss values, ranging from a slight diffusion for touch screens to a more matte finish for outdoor displays. Furthermore, the ability to apply additional treatments such as anti-fingerprint (AF), anti-reflective (AR) coatings, or hydrophobic properties can significantly enhance functionality. Edge processing options (e.g., polished, beveled, or drilled holes) and complex geometric cutting capabilities (CNC machining) are also vital for integration into diverse product designs. A flexible manufacturer can provide rapid prototyping and small-batch production for testing phases, scaling up efficiently for mass production while maintaining consistent quality. This tailored approach ensures that the glass perfectly meets the unique optical, mechanical, and aesthetic demands of each project, optimizing performance and user satisfaction.

Real-World Application Cases and Performance Metrics

The tangible benefits of premium anti glare etched glass are best illustrated through its successful deployment in demanding real-world applications. Consider a leading manufacturer of high-end outdoor payment terminals for gasoline stations. Prior to adopting anti-glare etched glass, their displays suffered from significant glare under direct sunlight, rendering them unreadable for customers and leading to transaction errors and frustration. By integrating custom-designed anti-glare etched glass with a specific haze value of 15% and a gloss of 55 GU, the company achieved a remarkable 70% reduction in visible glare, as measured by spectrogoniometer tests. This enhancement drastically improved readability and accelerated transaction times by an average of 15 seconds per customer, resulting in a significant uplift in customer satisfaction scores and a measurable increase in daily transaction volume, validating the ROI of the glass upgrade.

Another compelling case involves a medical device OEM developing advanced surgical monitors. Their challenge was ensuring unparalleled clarity and color accuracy for surgeons under various operating room lighting conditions, without reflections from overhead lights or surgical instruments. They opted for anti-glare etched glass with an ultra-low gloss value (below 40 GU) and high light transmission (>92%) to maintain image fidelity. Post-implementation, subjective user feedback from surgeons indicated a "dramatic improvement" in visual comfort and precision, while objective tests showed a 25% reduction in visual fatigue during prolonged surgeries. Furthermore, the inherent durability of the etched surface proved resilient to repeated cleaning with strong disinfectants, extending the lifespan of the monitor displays by an estimated 3 years compared to previous solutions. These examples underscore how tailored anti-glare etched glass solutions deliver measurable improvements in performance, user experience, and operational longevity across diverse, critical applications.

Frequently Asked Questions (FAQ)

Understanding the intricacies of premium anti glare etched glass can sometimes lead to specific questions regarding its functionality, procurement, and long-term support. Here are some of the most frequently asked questions by our B2B clients, along with comprehensive answers designed to provide clarity and instill confidence.

Q1: How does etched anti-glare glass differ from anti-glare coated glass?

A1: Etched anti-glare glass achieves its effect by physically altering the glass surface at a microscopic level, creating a permanent texture that diffuses light. This method offers superior durability, scratch resistance, and a consistent anti-glare performance over the product's lifespan, as the anti-glare property is an intrinsic part of the glass itself. In contrast, anti-glare coated glass relies on a thin film applied to the surface. While coatings can offer anti-glare properties, they are generally less durable, more susceptible to scratches, peeling, or degradation over time, and may have limited chemical resistance. For critical industrial and medical applications, the long-term reliability of etched glass is often preferred.

Q2: What is the typical lead time for custom anti-glare etched glass orders?

A2: Lead times for custom orders of anti-glare etched glass can vary depending on complexity, quantity, and specific customization requirements (e.g., unique dimensions, additional treatments like AF/AR coatings, CNC machining). Typically, for standard customization, initial prototyping and sample delivery might take 2-4 weeks. For mass production, lead times usually range from 6-10 weeks from the confirmation of specifications and receipt of purchase order. We emphasize transparent communication regarding production schedules and strive to meet critical deadlines, offering expedited services for urgent projects when feasible, ensuring timely delivery for your project’s success.

Q3: What kind of warranty and customer support do you offer for anti-glare etched glass products?

A3: We stand behind the quality and performance of our premium anti glare etched glass products with a comprehensive warranty against manufacturing defects, typically spanning 12 to 24 months from the date of delivery. Our dedicated customer support team provides expert technical assistance, from initial consultation and design optimization to post-sales support and troubleshooting. We are committed to ensuring customer satisfaction through prompt responses, detailed technical guidance, and reliable problem resolution. Our aim is to build long-term partnerships based on trust and consistent product excellence.

Further Resources and Industry Citations

- "Optical Properties of Glass: Measurement and Characterization." Journal of Applied Optics.

- "Surface Etching Techniques for Advanced Glass Substrates in Display Technology." Proceedings of the Society for Information Display.

- "Durability and Reliability of Anti-Glare Surfaces in Harsh Environments." International Journal of Materials Science and Engineering.

- "Ergonomic Impact of Display Glare on User Performance and Eye Strain." Human Factors and Ergonomics in Manufacturing & Service Industries.

- "Innovations in Glass Manufacturing for Automotive Displays." SAE International Journal of Materials and Manufacturing.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS