Sep . 15, 2025 09:40 Back to list

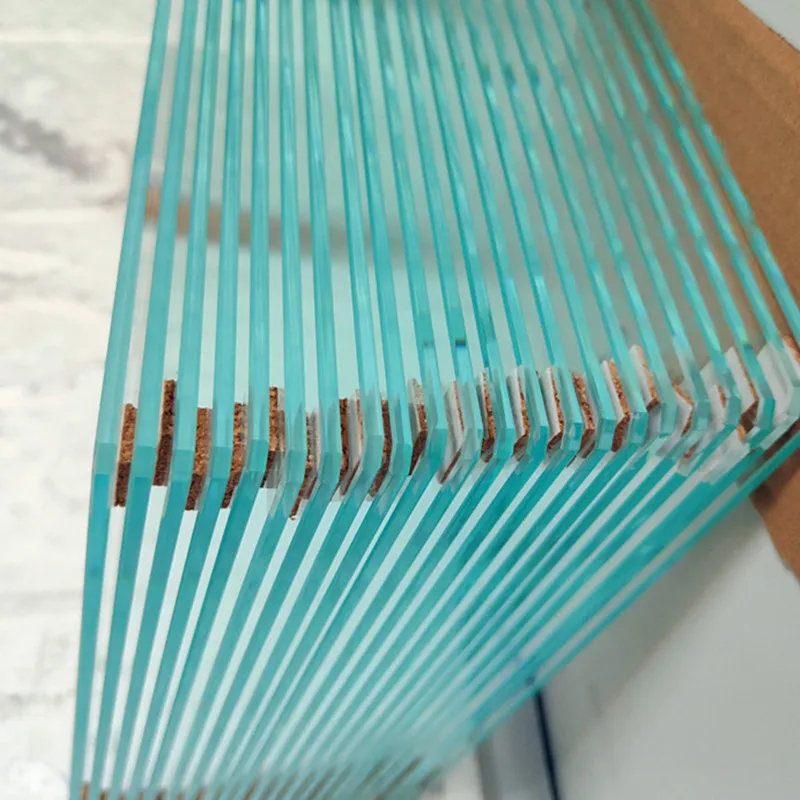

Premium Clear Float Glass: Optimal Clarity & Smoothness

Understanding Clear Float Glass: A Technical Deep Dive for B2B Professionals

In the realm of modern architecture, automotive, and specialized industrial applications, the demand for high-performance transparent materials is ever-growing. Among these, clear float glass stands out as a foundational material, renowned for its exceptional optical clarity, consistent thickness, and pristine surface quality. This comprehensive guide provides B2B decision-makers and technical engineers with an in-depth understanding of this critical material, covering its manufacturing intricacies, technical specifications, diverse applications, and market dynamics.

The versatility and reliability of clear float glass make it indispensable across numerous sectors, driving innovation in design and functionality. From large-scale architectural facades to precision optical components, its characteristics are meticulously engineered to meet stringent industry standards.

Industry Trends and Market Dynamics

The global clear float glass market is characterized by steady growth, primarily driven by urbanization, expanding construction sectors, and increasing demand for energy-efficient building materials. Innovations in glass processing, such as advanced coatings for thermal insulation and solar control, are continually enhancing its value proposition. Emerging trends include the integration of smart glass technologies, the push for larger glass panels for minimalist aesthetics, and the development of ultra-thin glass for electronics.

Asia-Pacific, particularly China, remains a dominant force in both production and consumption, influencing clear float glass price globally. The emphasis on sustainable practices and reduced carbon footprints also impacts manufacturing processes, pushing for more efficient energy consumption and waste reduction in production facilities. The demand for specialized products like 3mm clear float glass for specific automotive and display applications continues to grow, indicating market diversification.

Detailed Process Flow: Manufacturing Clear Float Glass

The production of clear float glass is a marvel of continuous industrial manufacturing, ensuring unparalleled uniformity and optical quality. This process is commonly known as the Pilkington float process. Key product materials include silica sand (approximately 70-72%), soda ash, dolomite, limestone, and cullet (recycled glass). These raw materials are meticulously blended to form a batch mixture.

Manufacturing Process Steps:

- Batch Preparation: Raw materials are weighed, mixed, and fed into a furnace.

- Melting (Casting): The batch is melted in a large furnace at approximately 1600°C. This high temperature ensures complete fusion and homogenization of the glass constituents.

- Floating on Molten Tin: The molten glass flows from the furnace onto a bath of molten tin. Glass, being lighter than tin, floats on its surface. The extreme smoothness of the tin surface imparts a perfectly flat and parallel finish to both sides of the glass ribbon, eliminating the need for traditional grinding and polishing. The thickness of the glass is controlled by the speed at which it is drawn from the tin bath.

- Annealing (Cooling): The glass ribbon, now solidified, enters an annealing lehr, a controlled cooling zone. Here, it is gradually cooled from around 600°C to room temperature. This slow cooling process relieves internal stresses, preventing cracking and enhancing the glass's strength and workability.

- Inspection and Cutting: After annealing, the continuous glass ribbon undergoes rigorous automated and manual inspection for defects. Once approved, it is cut into standard sizes or customized dimensions using precision cutting machinery.

Testing Standards and Service Life:

Quality assurance is paramount. Our clear float glass products adhere to international testing standards such as ISO 9001 for quality management, ISO 14001 for environmental management, and specific product standards like EN 572-2 (Europe) and ASTM C1036 (North America) for flat glass. These standards ensure dimensional accuracy, optical quality, mechanical strength, and chemical durability. The typical service life of properly installed clear float glass in building applications can exceed 50 years, demonstrating exceptional durability.

Target Industries and Advantages:

Clear float glass serves a wide array of target industries, including:

- Construction & Architecture: Facades, windows, doors, interior partitions, skylights. Advantages: Energy saving (when combined with coatings), natural light maximization, aesthetic appeal.

- Automotive: Windshields, side windows, rear windows. Advantages: High optical clarity for driver safety, base for laminates and tints.

- Furniture & Interior Design: Table tops, shelves, display cases. Advantages: Pristine finish, modern aesthetic.

- Solar Energy: Covers for solar panels. Advantages: High light transmittance, durability against environmental factors.

- Appliance & Electronics: Oven doors, display screens. Advantages: Heat resistance, scratch resistance.

In typical application scenarios, the material's inherent properties, such as excellent light transmission and surface flatness, translate into tangible benefits like enhanced energy efficiency in buildings (through optimized daylighting and reduced need for artificial lighting) and superior visual performance in display applications.

Technical Specifications and Performance Parameters

Understanding the precise technical parameters of clear float glass is crucial for engineers and procurement specialists. Below is a detailed table outlining key specifications, referencing typical values for various thicknesses, including popular dimensions like 3mm clear float glass.

Clear Float Glass: Typical Specifications

| Parameter | Unit | 3mm Thick | 6mm Thick | 10mm Thick |

|---|---|---|---|---|

| Nominal Thickness Tolerance | mm | ±0.2 | ±0.2 | ±0.3 |

| Light Transmittance (Visible) | % | ~90 | ~88 | ~85 |

| UV Transmittance | % | ~65 | ~55 | ~40 |

| Solar Factor (G-value) | - | ~0.87 | ~0.81 | ~0.75 |

| Density | kg/m³ | ~2500 | ||

| Modulus of Elasticity | GPa | ~70 | ||

| Hardness (Mohs) | - | ~6 | ||

These values are crucial for architects and engineers designing structures where light, heat, and structural integrity are critical considerations. For specialized applications requiring specific properties, further customization and testing may be necessary.

Application Scenarios and Technical Advantages

The inherent properties of clear float glass – high light transmission, flat surfaces, and excellent processability – make it suitable for a vast array of applications:

- Architectural Glazing: Widely used for windows, curtain walls, and glass doors in residential, commercial, and industrial buildings. Its clarity enhances natural daylighting, reducing reliance on artificial lighting and contributing to energy savings.

- Interior Design Elements: Partitions, balustrades, shower enclosures, and decorative panels. The flat surface provides an ideal substrate for various decorative techniques like sandblasting, etching, or printing.

- Automotive Glass: Forms the base for laminated and tempered safety glass used in vehicles. Its optical quality is critical for driver visibility and safety.

- Mirrors: The smooth, flat surface is perfect for silvering, creating high-quality mirrors with minimal distortion.

- Solar Energy Panels: Used as the transparent cover for photovoltaic modules, maximizing solar energy absorption due to its high transmittance.

- Display Cabinets & Furniture: Provides clear visibility for products in retail, museums, and homes, offering an elegant finish.

The primary technical advantages include its superior optical clarity (minimal distortion), consistent thickness across large sheets, and an exceptionally smooth, blemish-free surface. These characteristics make it an ideal base material for further processing, such as tempering, laminating, coating, and insulation, to achieve enhanced performance in areas like thermal efficiency, safety, and acoustics.

Vendor Comparison: Choosing Your Clear Float Glass Supplier

Selecting the right supplier for clear float glass involves evaluating several factors beyond just clear float glass price. Key considerations include product quality, adherence to international standards, customization capabilities, lead times, and after-sales support. As a leading manufacturer and exporter of china clear float glass, we pride ourselves on a commitment to quality and customer satisfaction.

Key Differentiation Factors:

| Feature | Typical Supplier (Standard) | Our Offering (Premium) |

|---|---|---|

| Quality Certifications | ISO 9001, local standards | ISO 9001, ISO 14001, CE, ASTM C1036, EN 572-2, stringent internal QC |

| Thickness Range | Standard (4mm-12mm) | 2mm to 19mm, including 3mm clear float glass |

| Maximum Sheet Size | 3660x2440mm | Up to 6000x3300mm for jumbo sizes |

| Optical Distortion | Minor acceptable levels | Virtually zero optical distortion |

| Customization | Limited cutting/edging | Extensive capabilities: cutting, edging, drilling, tempering, laminating, coating |

| Lead Time (Standard) | 3-4 weeks | 2-3 weeks, expedited options available |

Our deep experience and adherence to global manufacturing best practices ensure that our clear float glass products meet and often exceed the demanding requirements of international projects.

Customized Solutions and Case Studies

Recognizing that standard products may not always suffice, we offer extensive customization options for clear float glass to meet unique project specifications. This includes custom dimensions, edge work (polished, beveled, ground), drilling, cut-outs, and integration with advanced coatings for thermal, solar, or acoustic performance. Our engineering team collaborates closely with clients from conceptualization to delivery.

Application Case Study: Commercial High-Rise Facade

Client: Major international construction firm for a Class A office tower in a metropolitan area.

Challenge: The project required large, optically perfect clear float glass panels for the building's facade, optimized for natural light transmission while minimizing solar heat gain and providing excellent acoustic insulation. The panels also needed to withstand significant wind loads.

Solution: We supplied jumbo-sized clear float glass panels, customized for specific dimensions. These were then processed into high-performance Insulated Glass Units (IGUs), incorporating a low-emissivity (low-e) coating for thermal control and a laminated inner pane for acoustic dampening and enhanced safety. All glass met stringent European EN standards for structural integrity and thermal performance.

Result: The facade achieved exceptional aesthetic appeal, energy efficiency (reducing HVAC loads by an estimated 18%), and occupant comfort (noise reduction by 35dB), demonstrating the versatility and high performance achievable with customized clear float glass solutions.

Trust and Reliability: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ):

- Q1: What thicknesses of clear float glass do you offer?

- We offer a comprehensive range from 2mm to 19mm, including common dimensions such as 3mm clear float glass, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, and 19mm. Custom thicknesses may be available upon special request.

- Q2: What are the standard sheet sizes available?

- Our standard sizes include 2140x3300mm, 2440x3660mm, and 1830x2440mm. We also supply jumbo sizes up to 6000x3300mm and offer custom cutting to client specifications.

- Q3: Can your clear float glass be processed further (tempered, laminated, etc.)?

- Absolutely. Our clear float glass serves as an excellent base for various processing techniques, including tempering, laminating, insulating (double glazing), coating (low-e, solar control), edging, drilling, and sandblasting. We provide these value-added services in-house or through certified partners.

- Q4: What certifications does your clear float glass hold?

- Our products are manufactured under ISO 9001 and ISO 14001 certified systems. They comply with international standards such as ASTM C1036, EN 572-2, and AS/NZS 2208, among others, ensuring global applicability and quality.

Lead Time and Fulfillment:

For standard clear float glass orders, our typical lead time is 2-3 weeks from order confirmation to dispatch. Customized orders or large volumes may require 3-5 weeks, depending on the complexity of processing. We maintain robust supply chain management to ensure timely delivery and efficient logistics for both domestic and international shipments. Expedited options are available for urgent projects.

Warranty Commitments:

We stand behind the quality of our clear float glass products. All glass supplied carries a standard 10-year limited warranty against manufacturing defects that impair its primary function or appearance. This warranty covers issues such as delamination (for laminated glass), seal failure (for IGUs), and significant optical defects not present at the time of delivery. Specific warranty details are provided with each order and project contract.

Customer Support:

Our dedicated customer support team is available to assist with technical queries, order tracking, and after-sales service. We offer comprehensive support through multiple channels:

- Technical Consultation: Expert advice on glass specifications, applications, and processing.

- Order Management: Real-time updates on production and shipping status.

- After-Sales Service: Prompt resolution of any post-delivery issues or warranty claims.

We are committed to building long-term partnerships based on trust, quality, and exceptional service.

References:

- Pilkington. (n.d.). The Float Process. Retrieved from Pilkington Glass Official Website.

- International Organization for Standardization (ISO). (n.d.). ISO Standards for Glass. Retrieved from ISO.org.

- ASTM International. (n.d.). ASTM C1036-16 Standard Specification for Flat Glass. Retrieved from ASTM.org.

- European Committee for Standardization (CEN). (n.d.). EN 572-2: Glass in building – Basic soda-lime silicate glass products – Part 2: Float glass. Retrieved from CEN.eu.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS