Jul . 28, 2025 01:01 Back to list

Premium Frosted Glass Solutions – Custom Sizes & 5mm Options

Frosted glass is revolutionizing interior and industrial design with its combination of privacy, aesthetics, and robust technical properties. As demand rises for customized, high-performance solutions, understanding the technological details, supplier landscape, and specification data is vital for consultants, architects, and industrial buyers. This guide delivers an in-depth, data-driven overview of frosted glass — including variations such as cut frosted glass and 5mm frosted glass — with authoritative references and practical case studies.

According to market research (Grand View Research), the architectural glass sector, in which frosted glass plays a key role, is projected to grow at a CAGR of 6.5% through 2030, driven by:

- Demand for Privacy & Aesthetics: Increased usage in offices, hospitals, and upscale residences.

- Industrial Expansion: Applications in petrochemical, metallurgy, clean rooms, and lab environments.

- Energy Efficiency Regulations: Emphasis on sustainable, low-e glass and thermal control.

| Type | Process | Typical Thickness | Light Transmittance | Applications |

|---|---|---|---|---|

| Acid Etched | Etched with Hydrofluoric Acid | 3-15mm | 60-85% | Windows, Partitions |

| Sandblasted | Surface Grit Blasting | 4-12mm | 55-80% | Doors, Shower Enclosures |

| Cut Frosted Glass | Customized CNC/Waterjet | 4, 5, 6, 8, 10mm | 65-80% | Custom Installations |

| 5mm Frosted Glass | Acid/Sandblasted, Polished Edge | 5mm | 70-85% | Interior & Industrial |

- Material: High-quality float glass grade, purity & flatness per ISO 9050/EN 572.

- Process: Acid-etch, sandblast, CNC-cut for cut frosted glass projects.

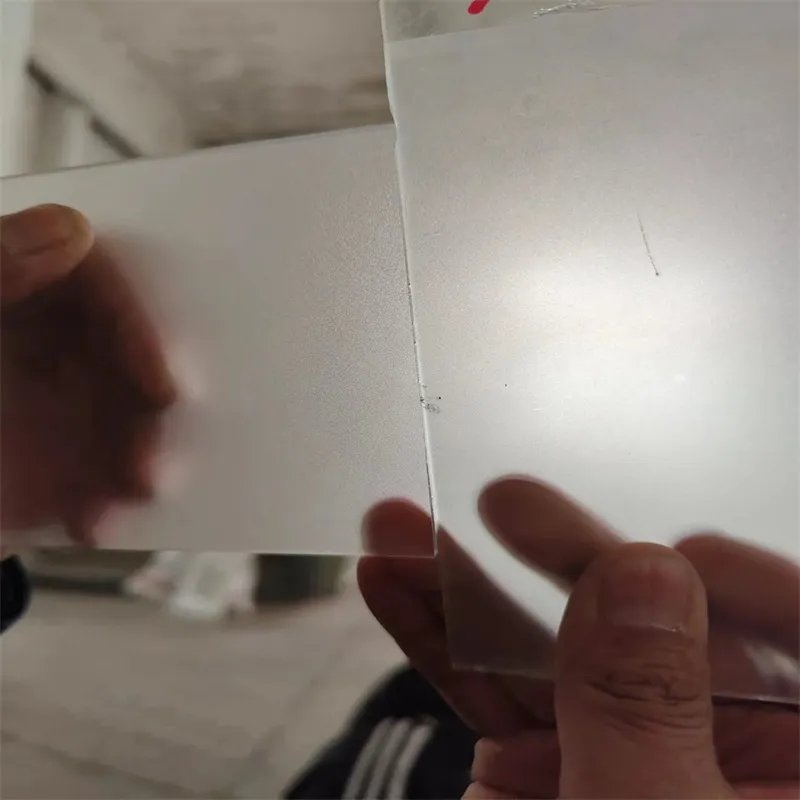

- Available Thickness: 5mm frosted glass is most popular for balancing privacy and light; available up to 19mm on request.

1. Float Glass Preparation (Key: EN 572 compliance) →

2. Cutting (CNC/Waterjet for cut frosted glass) →

3. Surface Treatment (acid etch or sandblast; particle size & acid concentration monitored per ASTM E2167) →

4. Washing & Curing →

5. Edge Finishing (polish/grind per requirement) →

6. Final Inspection (ISO 9001/ANSI Z97.1 standard tests for haze, transmission, surface flaw, impacts)

- Material: Float glass, optical clarity with iron content

-

Manufacturing Process:

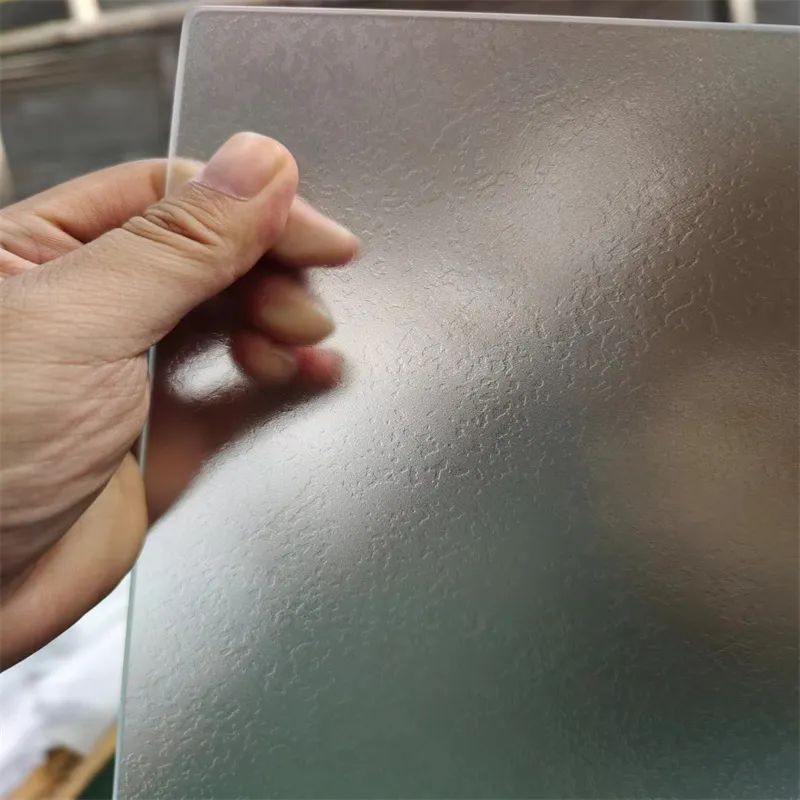

- Acid Etching: HF acid reaction forms a silica-haze surface for privacy and diffusion.

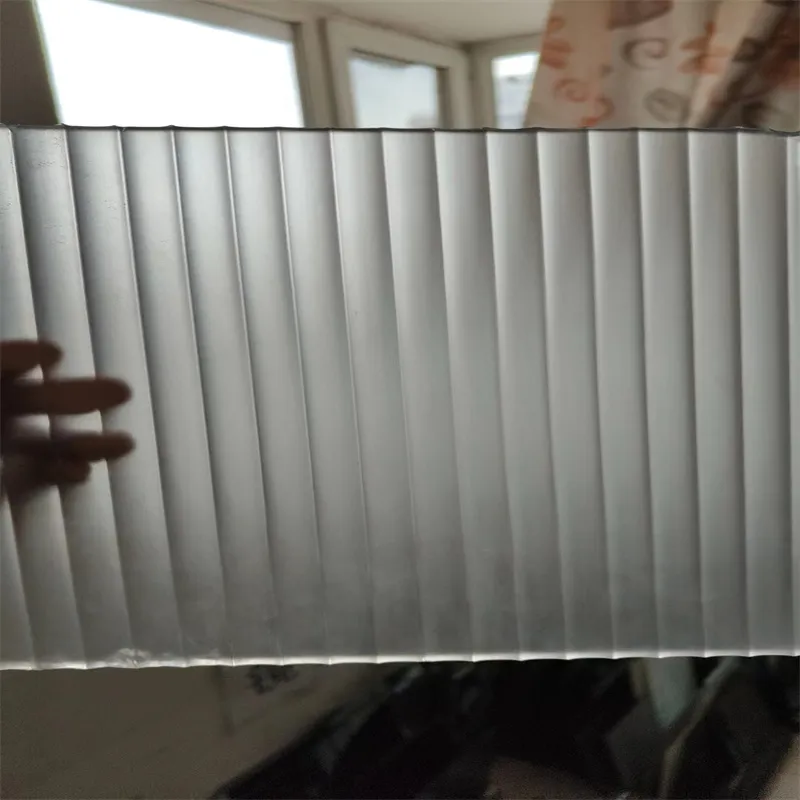

- Sandblasting: Abrasive blasting ensures uniform diffusion, widely chosen for patterns or cut frosted glass decorative use.

- CNC Cutting: Ensures cut frosted glass achieves custom shapes, holes, and slots to ±0.5mm tolerance.

- Quality Control: Online haze meters, visual flaw inspection, and mechanical stress tests per ISO 12543.

| Parameter | Frosted Glass | Clear Float Glass | Tinted Glass |

|---|---|---|---|

| Light Transmittance | 75% (±3%) | 90% (±1%) | 55% (±3%) |

| Haze Index | 92% (privacy) | 5% | 8% |

| UV Blocking Rate | 83% | 44% | 60% |

| Surface Hardness | 6-7 Mohs | 6-7 Mohs | 6-7 Mohs |

| Thermal Expansion | 8.0 x 10-6/°C | 8.0 x 10-6/°C | 8.0 x 10-6/°C |

| Corrosion Resistance | High | Medium | Medium |

| Custom Machining | Available | Available | Limited |

| Supplier | Product Range | Main Certifications | MOQ | Support for Custom Cut | Lead Time |

|---|---|---|---|---|---|

| Chinamirrorglass | 3-19mm, acid/sandblast, CNC, 5mm frosted glass, cut frosted glass | ISO 9001, EN 12150, ANSI Z97.1 | 100 m2 | Yes | 10-15 days |

| Saint-Gobain | Standard/Patterned, 4-12mm | CE, ISO 14001 | 300 m2 | No | 22-30 days |

| AGC Glass | Acid Etch, Tinted, 3-15mm | ISO 9001, RoHS | 200 m2 | Limited | 15-25 days |

| Guardian Industries | Patterned & Etched, 3-10mm | ISO 9001 | 150 m2 | Limited | 18-25 days |

- Identify required thickness, finish, and dimensions (e.g., 5mm frosted glass custom cut to size).

- Request product datasheets & compliance certificates (ISO, ANSI, etc.).

- Specify technical requirements: edges, holes, notches, surface quality.

- Place order with official PO; confirm inspection/pilot sample as needed.

Healthcare & Pharmaceuticals

- Laboratory partitions (EN 61340-5-1 ESD areas)

- ICU & ward privacy walls

- Easy to clean, surface resistant to chemical cleaning agents.

Commercial Interiors

- Office partitions, conference rooms (privacy + aesthetics)

- Shopping malls, glass doors

- Signage zones with custom logos on cut frosted glass

Industrial Facilities

- Chemical process windows (corrosion/chemical resistance)

- Petrochemical, metallurgy plants (acid-resistant partitions)

- Water treatment centers (hygienic, durable)

Residential & Hospitality

- Bathroom windows, shower screens

- Balcony dividers, sliding partitions

- Hotel lobbies and lifts: 5mm frosted glass for visual comfort

- Energy Efficiency: Frosted glass offers up to 27% reduction in solar gain compared to uncoated clear glass (see DOE Glazing Study).

- Corrosion & Longevity: Service life tested up to 25 years under simulated acid/alkali cycling (per AHRI-700).

- Precision Processing: Advanced CNC or waterjet enables cut frosted glass of any shape or slot (round/arched/rectangular). Dimensional accuracy ±0.5mm.

- Edge Finishes: Available as seamed, arrised, polished, or bevelled.

- Tolerance Control: Flatness per EN 572; hole diameter tolerance ±0.2mm.

- Composite/Double Glazed: Can be integrated with IGU for energy-efficient façade systems.

Project: Hospital Renovation

Glass: Cut frosted glass, 5mm, 1200x2800mm

Processing: CNC, acid-etched, polished edges;

Certification: ISO 9001, ANSI Z97.1, delivered within 14 days.

What materials are used for frosted glass manufacturing?

What are the recommended thicknesses for cut frosted glass?

What is the maximum dimension for a single frosted glass panel?

What is the typical surface haze index for privacy glass?

How is quality of frosted glass tested?

Can frosted glass be installed in wet areas (e.g. showers)?

What warranty & support is provided?

Customer Feedback: "Our laboratory partitions with 5mm frosted glass remain flawless after four years of intensive use..." — Johnson Controls, 2023 Facility Upgrade Report

Customer Service: 24h response, full technical documentation and installation manuals provided.

- 5mm frosted glass achieves the optimal balance between light transmittance, privacy, and structural performance (see chart below).

- Customization demand (“cut frosted glass”) has risen over 40% since 2021, indicative of the architectural trend for bespoke solutions (source: Statista).

- Industry-Leading Expertise: Over 15 years of engineering experience in architectural and industrial frosted glass supply, with full R&D and quality control.

- Full Certifications: Products certified to ISO 9001, EN 12150, ANSI Z97.1, CE Marking.

- Comprehensive Customization: Support for cut frosted glass (irregular geometry, surface patterns, holes, slots), sheet thickness 3–19mm.

- Warranty & Support: 5-year defect warranty, 24h support, OEM/ODM available.

- Reference Projects: Supplied to Huawei, Johnson Controls, and CRCC.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS