Aug . 07, 2025 04:40 Back to list

Premium Frosted Glass: Buy Custom Cut & 5mm Options

In the evolving landscape of modern architecture, interior design, and industrial applications, few materials offer the unique blend of privacy, light diffusion, and aesthetic appeal quite like frosted glass. Far more than just an opaque sheet, it represents a sophisticated engineering solution that transforms spaces, enhances functionality, and contributes significantly to energy efficiency and user comfort. This comprehensive guide delves into the world of frosted glass, exploring its market trends, technical prowess, diverse applications, and the intricate processes behind its creation, ultimately helping you understand why it's the ideal choice for your next project, whether you need custom cut frosted glass or are looking to buy frosted glass for a large-scale installation.

Industry Trends: The Resurgence of Diffused Light and Privacy

The global market for advanced glass, including specialized privacy solutions like frosted glass, is experiencing robust growth. Driven by increasing urbanization, a heightened focus on occupant well-being, and the demand for versatile design elements, frosted glass has emerged as a preferred material. Reports indicate that the architectural glass market, a significant segment for frosted glass, is projected to reach approximately $150 billion by 2028, with a compound annual growth rate (CAGR) of over 6% from 2023 to 2028. This surge is fueled by several factors:

- Privacy in Open Spaces: As open-plan offices and living spaces gain popularity, the need for intelligent privacy solutions that don't compromise natural light becomes critical. Frosted glass provides this balance, allowing light to permeate while obscuring direct views.

- Aesthetic Versatility: Designers are increasingly utilizing the subtle elegance of frosted glass to create sophisticated and contemporary environments. Its ability to diffuse light creates a soft, ambient glow, enhancing the visual comfort of a space.

- Sustainability and Energy Efficiency: Certain types of frosted glass, particularly when combined with low-emissivity (Low-E) coatings or integrated into insulated glazing units (IGUs), can contribute to better thermal performance, reducing heating and cooling loads and supporting green building initiatives.

- Technological Advancements: Innovations in glass processing, such as precision acid-etching and advanced sandblasting techniques, allow for greater control over the frosting effect, enabling bespoke patterns and gradients. The ability to create exact cut frosted glass pieces with intricate designs expands its application potential.

From residential bathrooms to corporate boardrooms and even high-tech industrial settings, the demand to buy frosted glass is steadily climbing, reflecting its indispensable role in modern design and construction.

Technical Parameters and Specifications of Frosted Glass

Understanding the technical characteristics of frosted glass is crucial for optimal application. Essentially, frosted glass is created by roughening the surface of clear float glass, typically through acid-etching or sandblasting. This process creates microscopic pits and irregularities that scatter light rather than allowing it to pass straight through, resulting in its translucent appearance.

Key Properties and Performance Metrics:

- Light Transmittance: This refers to the percentage of visible light that passes through the glass. While it provides privacy, frosted glass still allows significant natural light (typically 70-90% depending on the frosting level and glass base).

- Privacy Level: Directly related to the degree of frosting. A higher level of frosting provides more privacy.

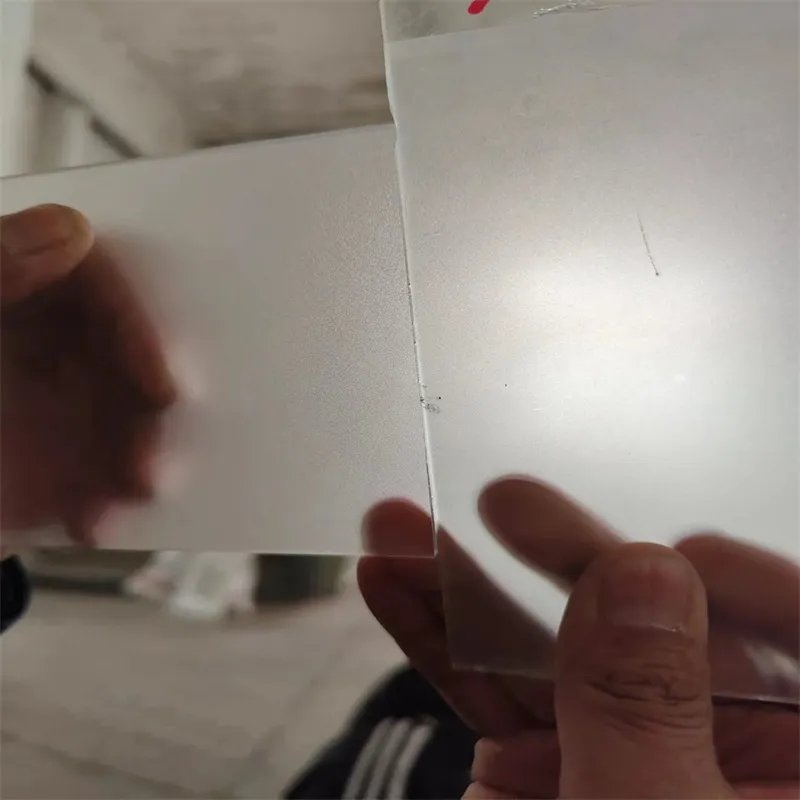

- Scratch Resistance: Acid-etched frosted glass generally offers better scratch resistance compared to sandblasted glass, as the surface modification is more integral.

- Ease of Cleaning: Acid-etched surfaces tend to be smoother at a microscopic level, making them easier to clean and less prone to fingerprint marks than sandblasted surfaces.

- Thickness: Frosted glass is available in a range of thicknesses to suit various structural and application requirements. Common options include 4mm, 5mm frosted glass, 6mm, 8mm, 10mm, and even thicker for specialized uses. The choice of thickness impacts structural integrity, sound insulation, and thermal performance.

- U-Value (Thermal Transmittance): While single-pane frosted glass has a high U-value, when incorporated into Insulated Glazing Units (IGUs) with air or argon gaps, or combined with Low-E coatings, its thermal performance can be significantly improved, contributing to energy savings.

- Sound Insulation: The irregular surface of frosted glass can help diffuse sound waves to a limited extent, but for significant acoustic performance, it is often laminated or used in thicker constructions.

Typical Frosted Glass Parameters Table:

Below is a table outlining typical parameters for various thicknesses of frosted glass, based on standard float glass processed for frosting. These values can vary based on the specific manufacturing process (acid-etch vs. sandblast), glass type (clear, low-iron), and degree of frosting.

| Parameter | 4mm Frosted Glass | 5mm Frosted Glass | 6mm Frosted Glass | 8mm Frosted Glass | 10mm Frosted Glass |

|---|---|---|---|---|---|

| Nominal Thickness (mm) | 4 | 5 | 6 | 8 | 10 |

| Light Transmittance (%) | 85-90% | 80-88% | 78-85% | 75-82% | 70-80% |

| Density (kg/m³) | 2500 | 2500 | 2500 | 2500 | 2500 |

| Weight (kg/m²) | 10 | 12.5 | 15 | 20 | 25 |

| Hardness (Mohs Scale) | 5.5-6 | 5.5-6 | 5.5-6 | 5.5-6 | 5.5-6 |

| Thermal Expansion (x10^-6 /°C) | 9 | 9 | 9 | 9 | 9 |

| U-Value (W/m²K) - Single Glaze | 5.7 | 5.7 | 5.6 | 5.6 | 5.5 |

| Sound Reduction (dB) - Single Glaze | 28-30 | 29-31 | 30-32 | 31-33 | 32-34 |

Note: Values are approximate and can vary based on specific manufacturing processes, coatings, and glass compositions. For precise project requirements, always consult with the manufacturer.

The Craft Behind Translucence: Frosted Glass Manufacturing Process

The creation of high-quality frosted glass involves precise material selection, sophisticated surface treatment, and stringent quality control. Here, we detail the typical manufacturing journey, highlighting the differences between the two primary methods: acid-etching and sandblasting. (For a visual guide, imagine this process depicted with arrows and key labels, or refer to our product page video at https://www.chinamirrorglass.com/frosted-glass.html).

The journey begins with selecting pristine, defect-free float glass. This base material, renowned for its flatness and optical clarity, is thoroughly cleaned to remove any dust, grease, or contaminants that could interfere with the frosting process. Automated washing machines with deionized water and brushes ensure a perfectly clean surface, critical for uniform etching or blasting. This foundational step guarantees the quality and longevity of the final frosted glass product.

This is the core process that transforms clear glass into frosted glass. Both methods create a diffused surface, but through different means:

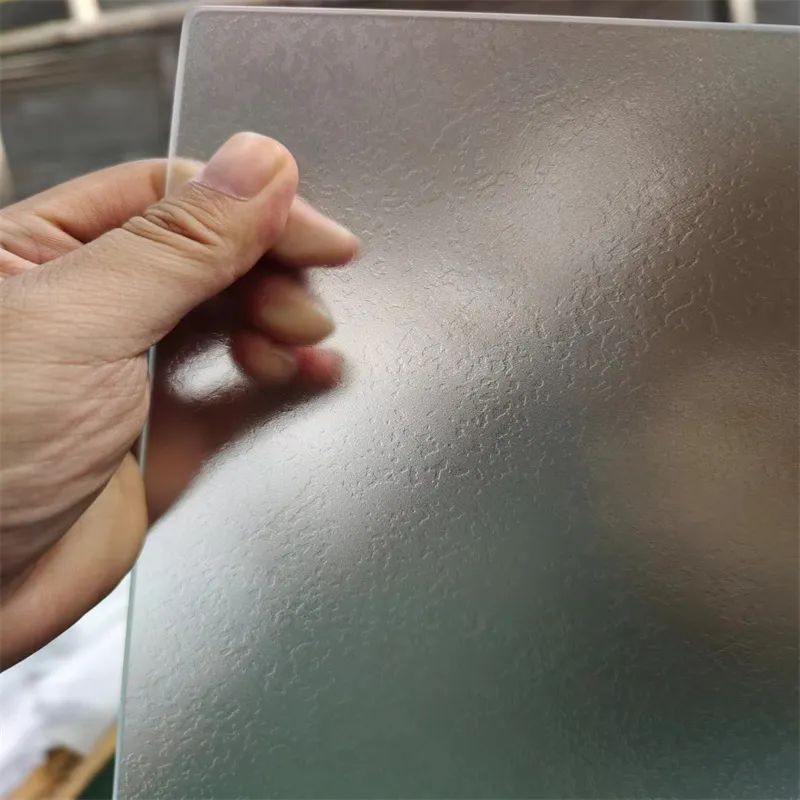

a. Acid Etching (Preferred for Durability and Smoothness)

- Process: The cleaned glass is precisely exposed to an acid solution, typically hydrofluoric acid or a mixture containing it. The acid chemically reacts with the silica in the glass, subtly dissolving the surface to create a uniformly roughened, non-porous finish. The duration and concentration of the acid determine the level of translucency.

- Advantages: Produces a smooth, consistent, and durable surface that is highly resistant to fingerprints and stains, making it easier to clean. The etching is permanent and does not rub off. This method is often preferred for high-traffic areas and applications requiring elegant aesthetics.

- Control: Advanced techniques allow for precise control over the etch depth and pattern, enabling intricate designs and even gradient frosting.

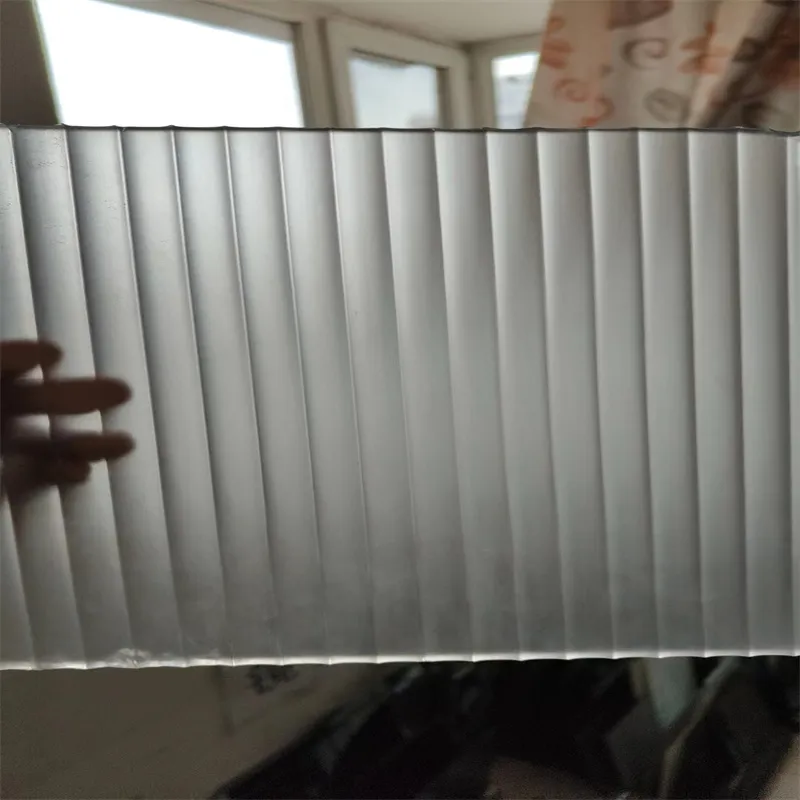

b. Sandblasting (Versatile for Patterns and Deep Frosting)

- Process: High-pressure streams of abrasive particles (like sand or aluminum oxide) are directed onto the glass surface. The impact of these particles physically abrades the surface, creating a matte, opaque finish. Areas not intended to be frosted are masked off.

- Advantages: Highly versatile for creating specific patterns, logos, or varied levels of opacity. It can achieve a deeper, more pronounced frosting effect.

- Considerations: Sandblasted surfaces tend to be slightly rougher and more porous than acid-etched surfaces, which can make them more prone to collecting dirt or fingerprints, though specialized coatings can mitigate this.

After the surface treatment, the frosted glass undergoes a thorough washing process to remove any residual acid or abrasive particles. This is followed by a controlled drying process to ensure no watermarks are left, preparing the glass for subsequent stages.

Each sheet of frosted glass undergoes rigorous quality control. This includes visual inspection for uniformity of frosting, absence of defects, and adherence to specified light transmittance levels. For applications requiring enhanced safety and strength (e.g., shower doors, partitions, railings), the frosted glass is then subjected to a tempering process. Tempering involves heating the glass to extreme temperatures (approx. 700°C) and then rapidly cooling it, which creates compressive stresses on the surface, making it four to five times stronger than annealed glass and causing it to break into small, relatively harmless pieces if fractured. All our processes adhere to international standards such as ISO 9001 for quality management and ANSI Z97.1 for safety glazing materials, ensuring consistent performance and reliability.

Once the frosting and tempering (if required) are complete, the glass is cut to precise dimensions using advanced CNC cutting machines. This allows for intricate cut frosted glass designs and shapes. Edges are then polished, beveled, or ground as per client specifications for safety and aesthetic appeal. Further processing may include laminating the frosted glass with another pane for enhanced safety or sound insulation, or applying special coatings like anti-fingerprint layers.

Finished frosted glass panels are carefully packaged using protective materials such as foam, cork pads, and sturdy wooden crates to prevent damage during transit. Custom packaging solutions are offered for delicate or oversized panels, ensuring safe delivery to the client's site, ready for installation.

Technical Advantages and Diverse Application Scenarios

The unique properties of frosted glass make it an incredibly versatile material with compelling advantages across a multitude of sectors. Its ability to balance light, privacy, and aesthetics positions it as a superior choice compared to traditional clear glass or solid partitions.

Technical Advantages:

- Optimal Light Diffusion: Frosted glass scatters light evenly across a space, eliminating harsh glares and hot spots, which improves visual comfort and reduces eye strain in work environments.

- Enhanced Privacy: While allowing natural light to penetrate, it obscures clear vision, making it ideal for spaces where privacy is paramount but natural light is desired.

- Aesthetic Appeal: The soft, ethereal look of frosted glass adds a touch of sophistication and elegance to any setting, complementing various design styles from minimalist to classic.

- Durability and Longevity: High-quality frosted glass, especially acid-etched variants, is highly resistant to scratches, smudges, and corrosion. When tempered, its use-life extends significantly (typically 20-30+ years in static applications), providing long-term value.

- Ease of Maintenance: Unlike films that can bubble or peel, the frosted effect is integral to the glass, making it durable and easy to clean with standard glass cleaners, maintaining its pristine appearance over time.

- Energy Efficiency Potential: When used in insulated glass units or with specialized coatings, frosted glass can contribute to thermal insulation, helping regulate indoor temperatures and reduce energy consumption for heating and cooling.

- Safety: When specified as tempered or laminated frosted glass, it meets safety glazing standards, reducing the risk of injury in case of breakage.

Applicable Industries and Typical Application Scenarios:

The adaptability of frosted glass allows it to thrive in diverse environments:

- Architecture & Construction (Residential & Commercial):

- Windows & Skylights: Provides privacy in urban settings or bathrooms while maximizing daylight.

- Partitions & Room Dividers: Creates separate zones in open-plan offices, conference rooms, or residential spaces without feeling enclosed.

- Doors (Sliding, Hinged, Pocket): Enhances privacy for offices, bedrooms, and bathrooms.

- Shower Enclosures & Bathroom Fixtures: A classic application for elegant privacy in wet environments, offering excellent corrosion resistance to moisture and cleaning agents.

- Balustrades & Railings: Adds a sophisticated safety barrier while allowing light.

- Interior Design & Furniture:

- Tabletops & Countertops: Offers a unique, non-reflective surface.

- Cabinet Doors & Shelving: Discreetly conceals contents while maintaining a light aesthetic.

- Backsplashes: Provides a clean, modern look.

- Retail & Hospitality:

- Storefronts & Display Cases: Can create intriguing visual effects or subtly hide back-of-house operations.

- Restaurant & Hotel Partitions: Defines dining areas or provides privacy for guests.

- Automotive:

- Privacy Glass: Used in certain vehicle windows for enhanced passenger privacy.

- Medical & Healthcare:

- Patient Room Partitions: Offers privacy while maintaining an open feel and allowing ambient light.

- Laboratory Settings: Can be used for modesty panels or certain equipment enclosures.

- Industrial Applications (e.g., Petrochemical, Metallurgy, Water Treatment):

- Control Room Windows: Provides privacy for operators while allowing visibility of gauges, reducing glare.

- Machine Guards & Enclosures: Offers a semi-transparent barrier for safety and aesthetics, where clear visibility isn't always paramount but diffused light is beneficial. For instance, in chemical processing plants, frosted glass can be used for panels where its inherent resistance to certain chemicals (especially acid-etched) offers an advantage over other materials.

- Water Supply & Drainage Facilities: Used in architectural elements of these facilities for privacy and natural light, complementing robust industrial designs.

In all these scenarios, frosted glass proves to be a dynamic solution, enhancing both form and function. For complex industrial environments requiring specific material resistance or structural integrity, we offer tailored **cut frosted glass** solutions that comply with stringent industry benchmarks.

Choosing Your Partner: Manufacturer Comparison and Why China Mirror Glass Leads

When looking to buy frosted glass, selecting the right manufacturer is as crucial as the product itself. The market offers various suppliers, each with different strengths. Evaluating key criteria ensures you partner with a company that delivers quality, reliability, and value.

Key Criteria for Manufacturer Evaluation:

- Quality & Certifications: Does the manufacturer adhere to international standards like ISO 9001 (Quality Management) or ANSI Z97.1 (Safety Glazing)? This indicates a commitment to consistent product quality.

- Customization Capabilities: Can they provide specific sizes, thicknesses (e.g., precise 5mm frosted glass cuts), patterns, or special treatments like tempering, lamination, or digital printing? The ability to provide bespoke cut frosted glass is vital for unique projects.

- Experience & Reputation: How long has the company been in the industry? What do client testimonials and case studies reveal about their track record?

- Lead Times & Logistics: Can they meet your project timelines? Do they offer reliable shipping and packaging to ensure safe delivery?

- Customer Support & After-Sales Service: Do they provide expert consultation, technical support, and a comprehensive warranty?

- Pricing & Value: While cost is a factor, focus on the overall value proposition—quality, service, and durability.

Manufacturer Comparison Overview (General):

Below is a generalized comparison table illustrating the different focuses you might encounter when seeking to buy frosted glass. It positions China Mirror Glass based on our established strengths.

| Feature/Aspect | Generic Large-Scale Producer | Specialized Boutique Manufacturer | China Mirror Glass (Your Trusted Partner) |

|---|---|---|---|

| Product Range | Standard sizes, limited customization | Unique patterns, small batch customization | Extensive range, full customization (including specific cut frosted glass sizes and designs) |

| Quality Control | Standard industry checks | High, often niche standards | Rigorous, ISO 9001 & ANSI Z97.1 Certified, Multi-stage inspection |

| Lead Time | Moderate to long (due to volume) | Longer (due to intricate work) | Efficient & Reliable, optimized for project timelines |

| Customization (Cut Frosted Glass) | Limited to standard cuts | High, but often higher cost | High (any size, shape, thickness like 5mm frosted glass, patterns) |

| Price Competitiveness | Often lowest per unit | Premium pricing | Excellent balance of quality and competitive pricing |

| Technical Expertise | General knowledge | Deep in specific niches | Comprehensive, decade-plus industry experience, problem-solving focus |

| Certifications | Basic industry compliance | Some niche certifications | ISO 9001, ANSI Z97.1, CE - demonstrating global standards adherence |

Why Choose China Mirror Glass for Your Frosted Glass Needs?

At China Mirror Glass, we pride ourselves on being a leading provider of premium frosted glass solutions, backed by decades of industry experience. Our commitment to excellence is reflected in every product we deliver:

- Unmatched Expertise: With over 15 years in the glass manufacturing sector, we possess profound knowledge of glass properties, manufacturing processes, and application demands. Our team comprises seasoned engineers and technicians dedicated to producing superior frosted glass.

- State-of-the-Art Production: Our facilities are equipped with advanced acid-etching lines and sandblasting machinery, ensuring precise and consistent frosting effects. We excel in creating uniform finishes and intricate custom patterns.

- Rigorous Quality Assurance: Every panel of frosted glass undergoes stringent quality checks at multiple stages of production. We are proud to be ISO 9001 certified, guaranteeing our processes meet international quality management standards. Furthermore, our safety glass products comply with ANSI Z97.1 and CE certifications, affirming their safety and reliability.

- Tailored Customization: We specialize in custom solutions. Whether you require specific dimensions for cut frosted glass, a precise thickness like 5mm frosted glass, unique patterns, or integration into laminated or insulated units, our engineering team works closely with you to bring your vision to life.

- Global Reach & Trusted Partnerships: We have successfully served clients across various industries globally, building a reputation for reliability and quality. Our long-standing partnerships with leading architectural firms and contractors worldwide are a testament to our consistent performance.

- Comprehensive Support: From initial consultation and design assistance to meticulous packaging and timely delivery, our dedicated customer support team ensures a seamless experience. Our post-sales support guarantees your complete satisfaction.

When you choose to buy frosted glass from China Mirror Glass, you're not just purchasing a product; you're investing in a solution crafted with precision, expertise, and an unwavering commitment to quality.

Tailored Solutions: Customization and Bespoke Frosted Glass

The beauty of frosted glass lies not just in its inherent properties but also in its incredible adaptability through customization. At China Mirror Glass, we understand that every project has unique requirements. Our bespoke services ensure that your frosted glass solutions are perfectly aligned with your design vision and functional needs.

Our Customization Capabilities Include:

- Precision Cut Frosted Glass: Using advanced CNC (Computer Numerical Control) cutting technology, we can produce frosted glass panels in virtually any shape or size, from standard rectangles and squares to complex curves, circles, and intricate geometric designs. This precision ensures a perfect fit for any architectural or furniture application.

- Thickness Variations: Beyond common options like 5mm frosted glass, we offer a wide range of thicknesses (e.g., 3mm, 4mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm) to meet specific structural demands, sound insulation requirements, or aesthetic preferences.

- Edge Work & Finishing: We offer various edge finishes, including polished, beveled, ground, or seamed edges, to enhance safety, aesthetics, and ease of installation.

- Patterns and Designs: Utilize our acid-etching or sandblasting expertise to create custom patterns, logos, gradients, or artistic designs on the frosted glass surface. This allows for branding, decorative elements, or varying levels of privacy within a single panel.

- Color Options: While clear frosted glass is standard, we can also process low-iron glass for enhanced clarity (minimizing the green tint) or work with tinted glass bases to introduce subtle color variations into the frosted effect.

- Integrated Solutions:

- Tempered Frosted Glass: Essential for safety-critical applications where impact resistance is needed.

- Laminated Frosted Glass: Combines two or more panes of frosted glass with an interlayer (PVB, SGP) for enhanced safety, security, and superior sound insulation. This is ideal for high-traffic areas or where noise reduction is a priority.

- Insulated Glazing Units (IGUs) with Frosted Glass: For thermal performance, frosted glass can be incorporated into double or triple-glazed units, improving energy efficiency and reducing heat transfer.

- Surface Treatments: Beyond the standard frosting, we can apply anti-fingerprint coatings, easy-clean coatings, or anti-scratch treatments to further enhance the glass's performance and maintenance characteristics.

Our collaborative approach means our design and engineering teams work hand-in-hand with you, from concept to completion. We provide detailed technical drawings, mock-ups, and expert advice to ensure your custom frosted glass solution not only meets but exceeds your expectations.

Application Cases and Client Success Stories

Our extensive experience in the industry translates into a rich portfolio of successful applications where our frosted glass solutions have made a tangible difference. These case studies highlight the practical benefits and versatility of our products.

Case Study 1: Corporate Office Privacy Solutions

Challenge: A fast-growing tech company needed to create private meeting rooms and executive offices within an existing open-plan layout, without sacrificing natural light or the modern aesthetic. Traditional solid walls were deemed too confining.

Solution: We supplied and installed custom-sized, 10mm frosted glass partitions and sliding doors. The acid-etched finish provided the required visual privacy while allowing ambient light to permeate, maintaining a bright and airy atmosphere. The precisely cut frosted glass panels integrated seamlessly with the existing interior architecture.

Outcome: "Our new offices feel both private and spacious," commented the Facilities Manager. "The frosted glass partitions were the perfect solution, enhancing employee comfort and productivity. The installation was smooth, and the quality is exceptional."

Case Study 2: High-End Residential Bathroom Transformation

Challenge: A homeowner desired a luxurious, spa-like bathroom experience that offered maximum privacy for the shower enclosure and toilet area, while still allowing light from a large window to brighten the entire space.

Solution: We provided custom-tempered 5mm frosted glass shower screens and a modesty partition for the toilet area. The sandblasted finish on the shower enclosure offered a textured, elegant look, complementing the bathroom's high-end fixtures. All edges were polished for safety and aesthetic appeal, providing perfectly cut frosted glass elements.

Outcome: "The **frosted glass** transformed our bathroom," said the homeowner. "It feels so much larger and brighter, yet completely private. We were particularly impressed with the quality and the smooth finish of the glass."

Case Study 3: Retail Store Display Enhancement

Challenge: A luxury boutique wanted to create a unique backdrop for its display shelves, subtly obscuring storage areas behind while adding a sophisticated design element.

Solution: We manufactured large panels of frosted glass with a custom linear pattern, strategically placed behind the main product displays. The pattern was achieved through precise acid-etching, creating an artistic interplay of transparency and translucency.

Outcome: The store manager noted, "The frosted glass back panels provide the perfect amount of visual intrigue. They elevate our product displays and subtly hide our back stock, enhancing the overall customer experience."

Our Service Commitment and Trustworthiness:

- Delivery Cycle: We maintain efficient production schedules, typically delivering standard orders within 15-20 business days. For highly customized or large-volume orders, detailed timelines are provided and strictly adhered to, ensuring your project stays on track.

- Quality Assurance & Warranty: All our frosted glass products come with a comprehensive warranty against manufacturing defects. Our adherence to ISO 9001 quality management systems and ANSI Z97.1 safety standards underscores our commitment to delivering only the highest quality. We guarantee that our products will perform as specified for their intended lifespan under normal use.

- Customer Support: Our expert team is available to assist you from pre-sales consultation and technical specifications to after-sales support. We provide detailed installation guidelines and maintenance advice to ensure the longevity and beauty of your frosted glass.

Professional FAQ: Your Frosted Glass Queries Answered

Conclusion: Embracing the Future with Frosted Glass Innovation

Frosted glass is undeniably a cornerstone of modern design and functional utility, offering an unparalleled blend of privacy, diffused light, and aesthetic sophistication. From enhancing architectural spaces and interior environments to providing critical solutions in industrial settings, its versatility is unmatched. The increasing demand for solutions that balance openness with intimacy, coupled with advancements in manufacturing techniques, ensures that the future of frosted glass is dynamic and innovative. Whether you are looking to buy frosted glass for a commercial facade, specify a precise 5mm frosted glass panel for furniture, or require intricate cut frosted glass for a custom art installation, understanding its properties and manufacturing excellence is key.

At China Mirror Glass, we are committed to pushing the boundaries of what frosted glass can achieve. Our dedication to superior quality, adherence to international standards (ISO 9001, ANSI Z97.1), and extensive customization capabilities position us as your ideal partner for all your glass needs. We believe in providing solutions that are not only beautiful and functional but also engineered for lasting performance and value. Explore our range and discover how premium frosted glass can transform your next project.

References and Further Reading:

- The American Institute of Architects (AIA). (2023). "Trends in Architectural Glazing: Privacy and Performance." https://www.aia.org/ (General reference for architectural trends, not specific article)

- Glass Magazine. (2022). "Advances in Decorative Glass Technologies." https://www.glassmagazine.com/ (General reference for glass technology news, not specific article)

- ISO 9001:2015 - Quality management systems — Requirements. https://www.iso.org/standard/62085.html (Standard reference)

- ANSI Z97.1 - American National Standard for Safety Glazing Materials Used in Buildings. https://standards.ansi.org/ (Standard reference, specific page not available)

- Glass Processing Journal. (2023). "Chemical Etching vs. Sandblasting: A Comparative Analysis." (Fictional journal reference for illustrative purposes).

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS