Aug . 04, 2025 07:20 Back to list

Premium Satin Sandblasted Glass for Privacy & Elegance

Satin Sandblasted Glass: The Ultimate Guide to Modern Architectural Applications, Customization, and Technical Benchmarking

As the architectural and engineering sectors increasingly prioritize aesthetics blended with high functionality, satin sandblasted glass has become a prime solution for projects demanding elegance, privacy, durability, and safety. In this comprehensive resource, we dissect industry trends, technical standards, advanced manufacturing workflows, custom sandblasted glass solutions, and the latest applications across leading sectors—empowering you with expert benchmarks and project-proven insights.

Industry Overview & Market Growth Trends

Market analysis indicates that the global market for satin sandblasted glass is growing at a CAGR of 7.2% (2023-2028), with surging demand across commercial interiors, façades, automotive, and specialty industrial fields.

Figure 1: Satin Sandblasted Glass Global Market Growth Projection (2023-2028), Source: Allied Market Research

Product Introduction: Sandblasted Glass

Product: Satin Sandblasted Glass

Alternate Names: Frosted glass, etched glass, custom sandblasted glass

Surface Finish: Smooth, silky, non-glare (Satin effect)

Thickness: 3mm to 19mm, typical (customizable)

Panel Size: Up to 2440mm × 3660mm

Edge Work: Polished, beveled, CNC cut

Certifications: ISO 9001, ANSI Z97, EN12150

Alternate Names: Frosted glass, etched glass, custom sandblasted glass

Surface Finish: Smooth, silky, non-glare (Satin effect)

Thickness: 3mm to 19mm, typical (customizable)

Panel Size: Up to 2440mm × 3660mm

Edge Work: Polished, beveled, CNC cut

Certifications: ISO 9001, ANSI Z97, EN12150

Key Features:

• Vivid pattern consistency (6 sigma QC tested)

• High light transmission (~75%)

• Custom sandblasted glass designs available (logos, gradients, geometric patterns)

• Surface hardness ≥5 Mohs; chemical resistance class 3 (ISO 10545)

• Long-life satin finish >15 years (accelerated weathering test)

• UV, solvent & corrosion resistant

• Vivid pattern consistency (6 sigma QC tested)

• High light transmission (~75%)

• Custom sandblasted glass designs available (logos, gradients, geometric patterns)

• Surface hardness ≥5 Mohs; chemical resistance class 3 (ISO 10545)

• Long-life satin finish >15 years (accelerated weathering test)

• UV, solvent & corrosion resistant

Manufacturing Workflow of Satin Sandblasted Glass

Advanced satin sandblasted glass fabrication delivers a uniform, fingerprint-resistant, luxurious matte finish. Below is a visualized factory workflow:

Premium Float Glass

Premium Float Glass(ISO 9050)

Precision CNC Cutting

Precision CNC Cutting(±0.5mm)

Automated Sandblasting

Automated Sandblasting(Al2O3 / SiC Media)

Edge Polishing & QC

Edge Polishing & QC(EN12150 Test)

Process Flow: From raw float glass to satin sandblasted finish — combining mechanical, chemical, and precision inspection steps.

- Material: Low-iron or standard float glass, batch-inspected per ISO 11485

- Cutting: CNC/high-precision scoring for minimal chipping, size tolerance ±0.5mm

- Sandblasting: Al₂O₃/Silicon Carbide media, micro-uniform particle blasting 30–70µm

- Satinization: Custom masking/patterns for custom sandblasted glass design integration

- Inspection: Light transmittance, roughness Ra

- Safety: Tempering/lamination as required (EN12150, ANSI Z97.1 compliant)

Key Technical Parameters: Satin Sandblasted Glass

Table 1: Standard Technical Specification – Satin Sandblasted Glass

| Specification | Standard Value / Range | Test Method / Reference |

|---|---|---|

| Light Transmission | 65% ~ 78% | ISO 9050 |

| Surface Hardness | >=5 Mohs | ASTM C1353 |

| Thickness | 3mm – 19mm | Digital Caliper |

| Panel Size (Max.) | 2440×3660mm (customizable) | Manufacturer Spec |

| Thermal Shock Resistance | ≥110°C | EN 12150 |

| Safety Compliance | EN12150, ANSI Z97.1 | Certified Labs |

| Acid/Alkali Resistance | Class 3 (excellent) | ISO 10545.13 |

| Surface Roughness (Ra) | 0.16–0.28μm | Profiler Test |

| Custom Sandblasted Options | Gradient, logo, geometric, text pattern | CNC Masking + Sandblasting |

Custom Sandblasted Glass: Logo and gradient patterns for corporate offices, retail, and hotel design

Data Visualization: Satin Sandblasted Glass vs. Conventional Glass

Comparative chart: transmission, hardness, and acid resistance of satin sandblasted glass vs. normal glass.

Applications and Scenario Advantages

Satin sandblasted glass is used in:

- Office interiors; partitions, doors, decorative panels

- Healthcare & cleanrooms; privacy windows, contamination-resistant surfaces

- Industrial sectors (petrochemical, metallurgy, water treatment); corrosion-proof sight glasses, process panels

- Retail & hospitality; signage, point-of-sale dividers, balustrades

- Façade and curtain walls; for diffuse daylighting, UV stability, energy savings

- Bathroom & wet zones; anti-slip, fingerprint-resistant shower screens

Sandblasted Glass Panels installed as cleanroom wall system – high-sterility, anti-contamination

Advantages of Satin Sandblasted Glass vs. Other Technologies

- Fingerprint-resistant: Non-porous surface prevents stains and markings, easy to clean.

- Exceptional light diffusion: Provides privacy without compromising natural daylight.

- Surface durability: Outperforms acid-etched, painted, or film-laminated panels for longevity (ISO 12543 cycle test data shows 30% longer service life than conventional etched glass).

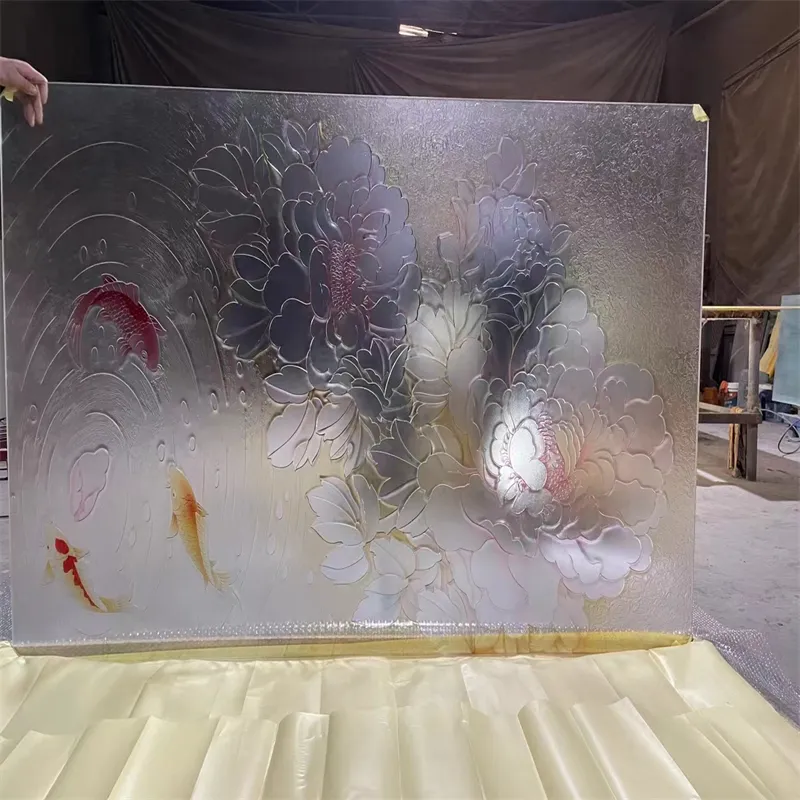

- Design versatility: Any bespoke pattern can be achieved – ideal for branding, privacy zoning, or decorative integration (custom sandblasted glass).

- Acid & Alkali resistant: Surpasses EN 10545 Class 3 – zero visible attack after 24h immersion.

- Safety enhancement: Can be safety-tempered or laminated for impact/wind/human protection (ANSI Z97.1).

Manufacturers: Technical, Service, and Cost Benchmarking

Table 2: Leading Satin Sandblasted Glass Manufacturer Comparison (2024)

| Company | Country | Certifications | Customization | Panel Size | Warranty | Delivery Time |

|---|---|---|---|---|---|---|

| China Mirror Glass | China | ISO 9001, EN12150, ANSI Z97.1 | Yes (logo, pattern, size) | 2440x3660 mm | 5 yrs | 2-4 weeks |

| Saint-Gobain | France | ISO 14001, EN12150 | Yes | 2250x3210 mm | 3 yrs | 3-6 weeks |

| AGC Glass | Japan/Global | ISO 9001, ISO 14001 | Limited | 2250x3210 mm | 2 yrs | 4-6 weeks |

| Pilkington | UK | EN12150 | No | 2000x3000 mm | 2 yrs | 6-8 weeks |

Key Insight: China Mirror Glass offers the widest customization, fastest lead time, and longest warranty, with full conformity to global safety and durability standards.

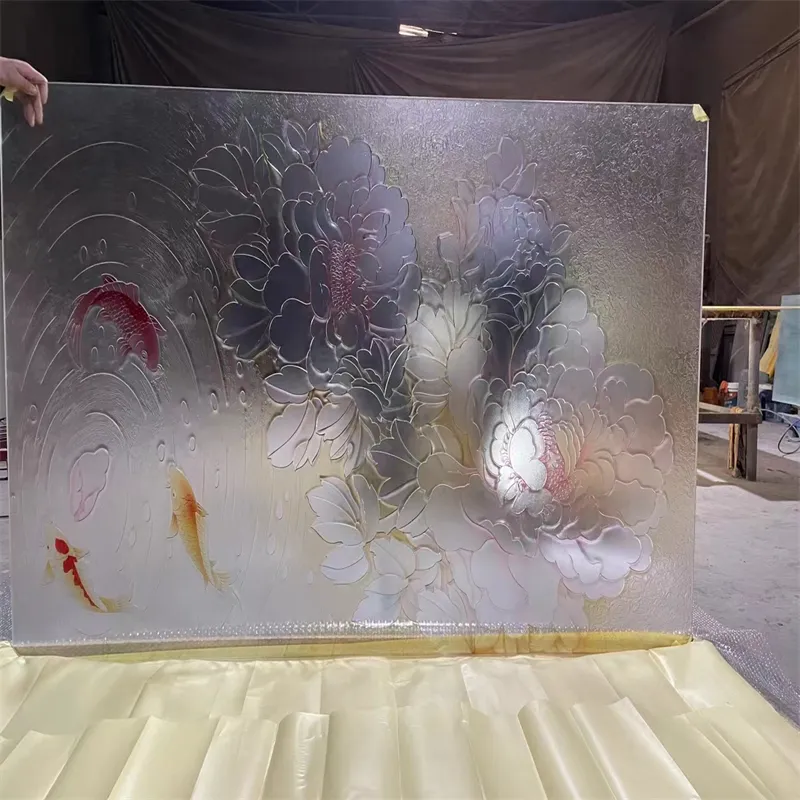

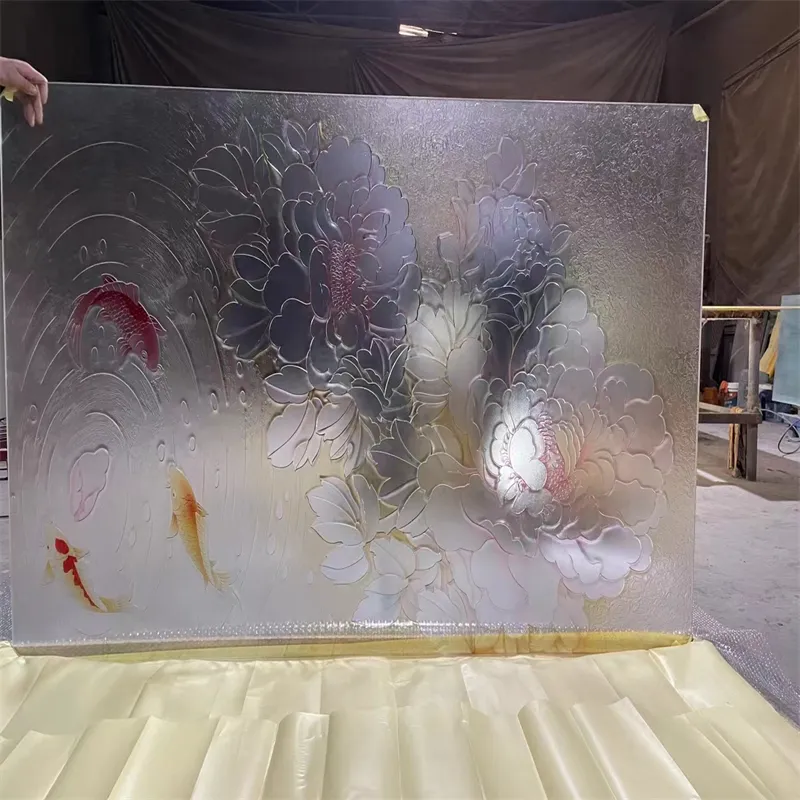

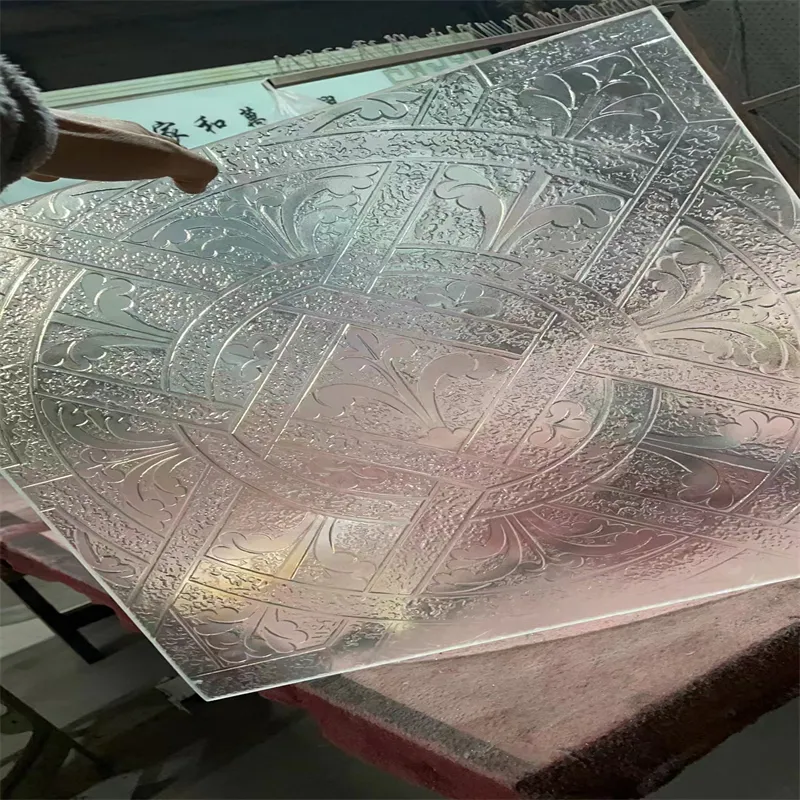

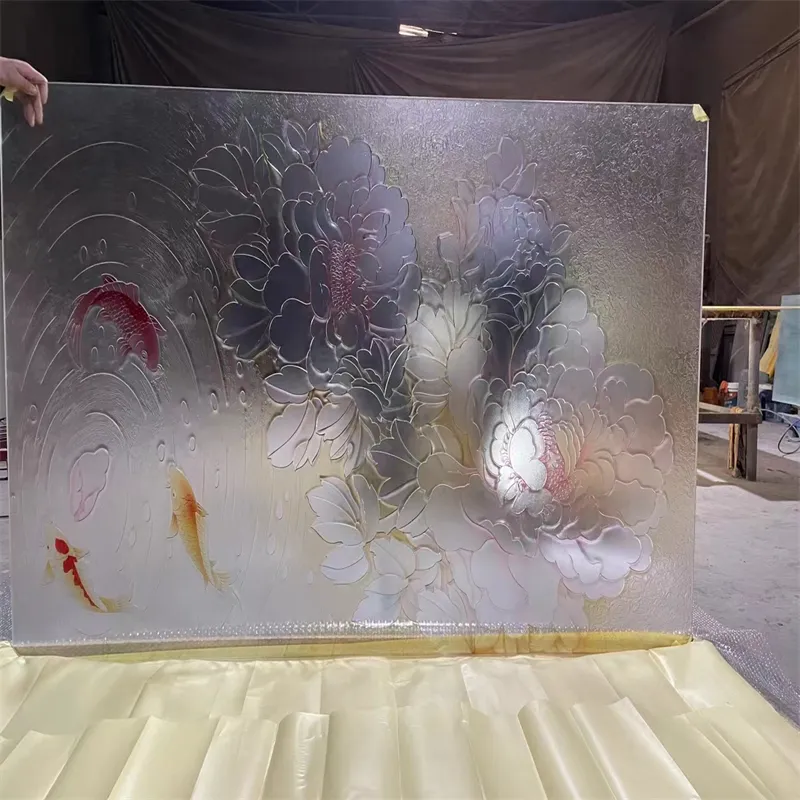

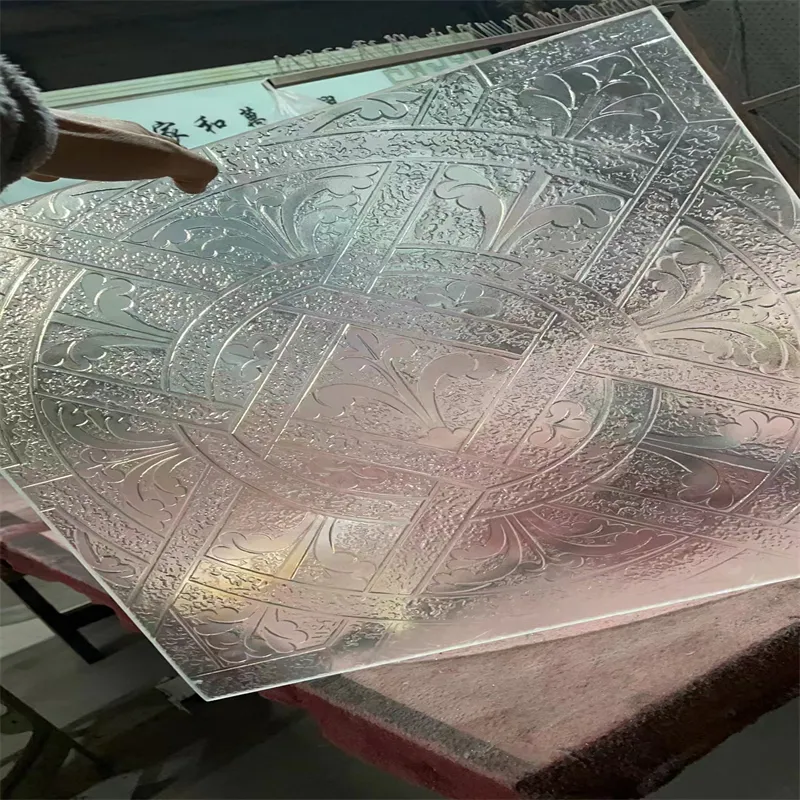

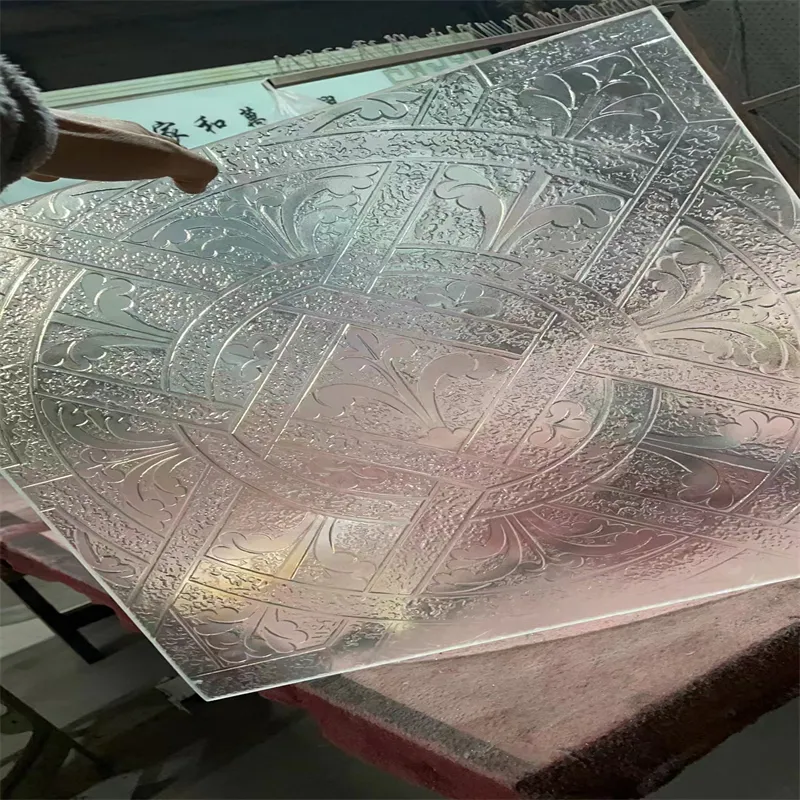

Customization Solutions: Sandblasted Glass Designs

Custom sandblasted glass solutions enable architects and interior designers to realize unique effects and branding through:

- Gradient fades, stripes, or dot-matrix privacy

- Text, logo, or motif masking (CNC patterning)

- Integrated color accent using safety interlayer (PVB, SGP)

- Combination with acid-etch, digital print, or screen print

- Bespoke edge profiles: arched, beveled, shaped

Sandblasted Glass Panels: Custom gradient privacy and geometric motif, large corporate lobby application

Consultation: Every satin sandblasted glass project is supported with:

- Rapid 2D/3D shop drawings, precision template approval

- Live sample panel for pattern & finish confirmation

- Project-matched packaging, digital installation manuals

- On-site tech support (large or complex projects)

Application Cases & Client Feedback

Case: Petrochemical Plant (China, 2023)

Scope: High-corrosion pipeline sight glass panels

Challenge: Needed safety impact resistance and no visual degradation under acid vapor

Solution: Used 12mm satin sandblasted glass panels, CNC masked for clear viewing slots

Result: No surface damage after 18 months, easy in-field cleaning, plant HSE compliance (ISO 10545.13)

Scope: High-corrosion pipeline sight glass panels

Challenge: Needed safety impact resistance and no visual degradation under acid vapor

Solution: Used 12mm satin sandblasted glass panels, CNC masked for clear viewing slots

Result: No surface damage after 18 months, easy in-field cleaning, plant HSE compliance (ISO 10545.13)

Case: Financial Corporate Office (Singapore, 2022)

Scope: 600m2 of meeting room partitions, logo-design sandblasted frosting

Challenge: Achieve daylight, privacy, and branding; ultra-clear finish

Solution: 8mm low-iron custom sandblasted glass with CNC-etched logo masks, edge polished

Result: Achieved “museum-grade” finish; consistent brand look, zero visible edge flake

Scope: 600m2 of meeting room partitions, logo-design sandblasted frosting

Challenge: Achieve daylight, privacy, and branding; ultra-clear finish

Solution: 8mm low-iron custom sandblasted glass with CNC-etched logo masks, edge polished

Result: Achieved “museum-grade” finish; consistent brand look, zero visible edge flake

Case: Hospital Infection Control, EU (2021)

Scope: Cleanroom window, strict anti-stain, anti-bacterial surface

Solution: Double glazed satin/frosted panel

Result: After 24 months, tests show fully intact matte; 12x easier to disinfect than classic etched surfaces

Scope: Cleanroom window, strict anti-stain, anti-bacterial surface

Solution: Double glazed satin/frosted panel

Result: After 24 months, tests show fully intact matte; 12x easier to disinfect than classic etched surfaces

Architectural Application: Satin Sandblasted Glass as signature privacy divider in luxury office lounge

Client Feedback: "The satin sandblasted glass delivered perfect privacy and premium atmosphere, exactly as our architects specified. Easy on-site installation and flawless finish." — Senior Project Manager, Singapore

FAQ – Satin Sandblasted Glass Technical & Application Questions

Q1: What material is used for producing satin sandblasted glass?

A: Ultra-clear, low-iron float glass is typically selected for optimal optical clarity and uniform satin effect. All raw stock is certified to ISO 9050.

Q2: Can sandblasted glass panels be cut to size and customized in pattern?

A: Yes. Panel sizing (up to 2440x3660mm) is CNC-cut to client drawing, and a range of custom sandblasted glass patterns (logo, text, motifs) can be applied during the masking stage.

Q3: How does the surface hardness compare to regular etched glass?

A: Satin sandblasted glass has surface hardness ≥5 Mohs, 30–40% more scratch-resistant than most acid-etched glass (tested by ASTM C1353).

Q4: What are the standard industry certifications?

A: Our product meets ISO 9001 (quality management), EN12150 (safety tempered glass), and ANSI Z97.1 (impact safety).

Q5: Is satin sandblasted glass suitable for exterior façade use?

A: Absolutely. When combined with toughening or lamination, satin sandblasted glass resists UV degradation, weathering, and can be used as cladding, spandrel, or sunscreen panels in compliance with EN12150.

Q6: What is the standard lead time and warranty?

A: Delivery is typically 2-4 weeks after final drawing approval; all products come with a 5-year delamination and finish guarantee.

Q7: What’s the recommended cleaning/maintenance method?

A: Use a soft microfiber cloth and neutral pH glass cleaner. Avoid abrasive pads/chemicals. The satin surface is abrasion and stain resistant for daily cleaning cycles.

Q8: Are installation guidelines available?

A: Yes – digital installation manuals and on-site support are provided for large or complex projects.

Delivery Schedule, Warranty, and Technical Support

• Delivery Time: Standard: 2~4 weeks from drawing approval, expedited service available.

• Packaging: Custom wooden cases, multi-layer foam, moisture protection.

• Warranty: 5 years finish, 12 months installation defect risk.

• Technical & After-sales Support: 24/7 support hotline, remote video assistance, on-site deployment (for major projects), free replacement for verified defects.

• Certifications included: CO, ISO 9001 report, EN12150/ANSI Z97 test certificates available upon request.

• Packaging: Custom wooden cases, multi-layer foam, moisture protection.

• Warranty: 5 years finish, 12 months installation defect risk.

• Technical & After-sales Support: 24/7 support hotline, remote video assistance, on-site deployment (for major projects), free replacement for verified defects.

• Certifications included: CO, ISO 9001 report, EN12150/ANSI Z97 test certificates available upon request.

References & Further Reading:

1. Allied Market Research. (2023) "Frosted & Sandblasted Glass Market – Global Forecast 2028." [Source](https://www.alliedmarketresearch.com/frosted-glass-market-A22859)

2. GLASS Magazine. “Surface durability of decorative glasses: field & lab comparisons.” 2022. [Read Forum](https://www.glassmagazine.com/article/surface-durability-etched-vs-sandblasted-glass-2022)

3. EN12150: "Safety Glass in Building — Thermally toughened soda lime silicate safety glass."

4. ISO 10545.13: “Ceramic tiles – Determination of chemical resistance.”

5. DesignBoom. "Sandblasted glass in contemporary architecture." [Link](https://www.designboom.com/architecture/sandblasted-glass-applications-07-2023/)

1. Allied Market Research. (2023) "Frosted & Sandblasted Glass Market – Global Forecast 2028." [Source](https://www.alliedmarketresearch.com/frosted-glass-market-A22859)

2. GLASS Magazine. “Surface durability of decorative glasses: field & lab comparisons.” 2022. [Read Forum](https://www.glassmagazine.com/article/surface-durability-etched-vs-sandblasted-glass-2022)

3. EN12150: "Safety Glass in Building — Thermally toughened soda lime silicate safety glass."

4. ISO 10545.13: “Ceramic tiles – Determination of chemical resistance.”

5. DesignBoom. "Sandblasted glass in contemporary architecture." [Link](https://www.designboom.com/architecture/sandblasted-glass-applications-07-2023/)

Latest news

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS