Oct . 08, 2024 05:42 Back to list

tempered glass manufacturers

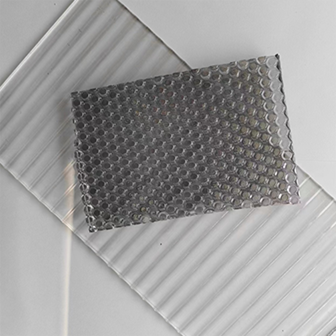

Tempered Glass Manufacturers Pioneers of Durability and Safety

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated by controlled thermal or chemical processes to increase its strength compared to normal glass. This transformative process results in a glass that is not only stronger but also shatters into small, blunt pieces rather than sharp shards, significantly reducing the risk of injury. With the growing demand for safety and durability in construction, automotive, and other industries, tempered glass manufacturers play a crucial role in providing high-quality products that meet safety standards.

The process of manufacturing tempered glass begins with the selection of raw materials. High-quality silica sand, soda ash, and limestone are blended to create the glass mixture. The initial melting process in a furnace creates a uniform glass sheet, which is then cut to the desired size. However, the true transformation occurs during the tempering process. The glass is heated to temperatures exceeding 600 degrees Celsius and then rapidly cooled. This thermal shock strengthens the glass, enabling it to withstand greater impact and thermal stress.

One of the primary advantages of tempered glass is its resistance to breakage and thermal stress, making it ideal for a wide range of applications. In the architectural industry, tempered glass is widely used in windows, facades, and doors due to its ability to withstand harsh weather conditions and UV rays. Additionally, its aesthetic appeal enhances the overall look of buildings. In the automotive sector, tempered glass is used in car windows and sunroofs, providing safety and clarity while driving.

tempered glass manufacturers

Tempered glass manufacturers are also committed to sustainability. Many companies have adopted eco-friendly practices, such as recycling waste glass and using energy-efficient processes. By prioritizing sustainability, manufacturers can reduce their environmental footprint while meeting the demands of environmentally conscious consumers and businesses.

When choosing a tempered glass manufacturer, several factors should be considered. Firstly, the manufacturer’s compliance with international safety standards, such as ASTM or EN standards, is crucial. This ensures that the glass products meet the necessary safety and quality benchmarks. Secondly, manufacturers should offer a variety of options in terms of thickness, tinting, and coatings to cater to different needs and preferences. Customization is essential for architects and designers looking to create unique structures or products.

Furthermore, customer service and technical support are vital attributes of a reputable tempered glass manufacturer. The complexities of construction and design often require expert advice, and having a manufacturer that can provide guidance on product selection and installation can make a significant difference.

In conclusion, tempered glass manufacturers are at the forefront of innovation and safety in the glass industry. Their commitment to quality, sustainability, and customer satisfaction plays a pivotal role in various sectors, enhancing both functionality and aesthetics. As the demand for durable and safe materials continues to rise, these manufacturers will remain essential partners in the construction and design processes. Their impact on building safety and design is profound, ensuring that tempered glass continues to be a preferred choice in modern applications.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS