Apr . 09, 2025 16:57 Back to list

The Process and Applications of Custom Glass Fabrication

Custom glass fabrication is a precise manufacturing process that transforms raw glass into specialized products tailored to specific functional and aesthetic requirements. This industry serves a wide range of sectors, including architecture, interior design, automotive, and retail. The process involves cutting, shaping, tempering, laminating, and finishing glass to achieve desired properties such as strength, safety, light diffusion, and visual appeal. Unlike standard glass production, custom glass fabrication allows for modifications in thickness, texture, color, and structural reinforcement. The ability to produce bespoke glass solutions makes it essential for modern construction and design, where both performance and appearance are critical considerations.

Techniques in Custom Glass Fabrication

The fabrication of custom glass involves several techniques, each suited to different design and functional needs. One common method is sandblasting, which creates a frosted or textured surface. Custom sandblasted glass is often used for privacy in office partitions or decorative elements in doors and windows. A variation of this technique produces frosted sandblasted glass, which diffuses light while maintaining transparency.

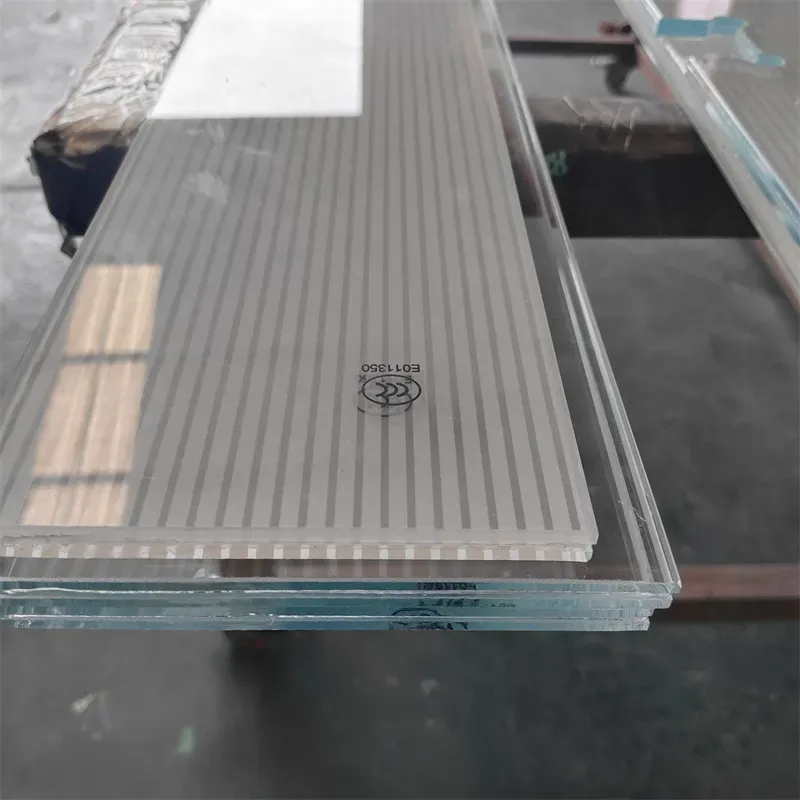

Another critical technique is lamination, where multiple layers of glass are bonded with an interlayer for added strength and safety. White laminated glass is a popular choice for modern interiors due to its clean appearance and light-diffusing properties. Similarly, custom laminated glass can be tailored in thickness, color, and texture to suit specific structural or decorative needs. Large laminated glass panels are frequently used in skylights, balustrades, and soundproof partitions.

For illuminated applications, glass can be combined with LED lighting to create functional and decorative mirrors. A round lighted mirror is commonly installed in bathrooms and dressing areas, providing even illumination. Custom lighted mirrors offer flexibility in shape, size, and lighting intensity, making them suitable for various settings. Illuminated bathroom mirrors enhance visibility while adding a modern touch to the space. Similarly, an LED vanity mirror is designed for precision lighting, often used in makeup and grooming areas.

Materials Used in Custom Glass Fabrication

The choice of materials in custom glass fabrication depends on the intended application. Tempered glass is often used for its safety features, as it shatters into small, blunt pieces rather than sharp shards. Laminated glass, as mentioned earlier, provides additional security and sound insulation.

For decorative purposes, textured and colored glass options are available. Frosted sandblasted glass is achieved by blasting the surface with fine abrasives, creating a semi-opaque finish. Tinted glass can reduce glare and UV exposure, making it suitable for windows and facades.

In illuminated glass products, energy-efficient LED lights are embedded or framed around the glass. These lights are long-lasting and provide consistent brightness, as seen in illuminated bathroom mirrors and LED vanity mirrors. The integration of lighting requires precise engineering to ensure even light distribution and minimal heat emission.

Applications of Custom Glass Fabrication

Custom glass fabrication serves a wide range of industries. In architecture, glass is used for facades, windows, and interior partitions. Laminated glass panels are particularly useful in high-traffic areas due to their durability and safety features.

In interior design, glass enhances both functionality and aesthetics. Custom sandblasted glass can be used for shower enclosures, offering privacy without sacrificing natural light. Mirrors with integrated lighting, such as custom lighted mirrors, are increasingly popular in modern homes and hotels. The automotive industry also benefits from custom glass fabrication, particularly in the production of windshields and sunroofs. Laminated glass ensures passenger safety by preventing shattering upon impact.

Retail and hospitality spaces often use decorative glass elements to create visually appealing displays. Frosted or etched glass can be used for branding or decorative partitions.

Custom glass fabrication plays a crucial role in modern design and construction by providing tailored solutions that balance functionality, safety, and visual appeal. Whether used in architectural installations, interior design elements, or specialized automotive components, fabricated glass products offer versatility and durability. The industry continues to evolve with advancements in materials and manufacturing techniques, enabling more innovative applications. From white laminated glass in contemporary interiors to round lighted mirrors in luxury bathrooms, the demand for high-quality, customized glass solutions remains strong. As technology progresses, the potential for new applications in smart glass and energy-efficient designs will further expand the possibilities within this field.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS