May . 25, 2025 08:37 Back to list

Toughened & Laminated Glass Safety, Strength & Versatility

- Introduction to Toughened and Laminated Glass

- Technical Advantages: Strength and Safety

- Manufacturer Comparison: Key Performance Metrics

- Custom Solutions for Diverse Applications

- Real-World Case Studies

- Maintenance and Longevity Best Practices

- Why Choose Toughened and Laminated Glass?

(toughened and laminated glass)

Understanding Toughened and Laminated Glass

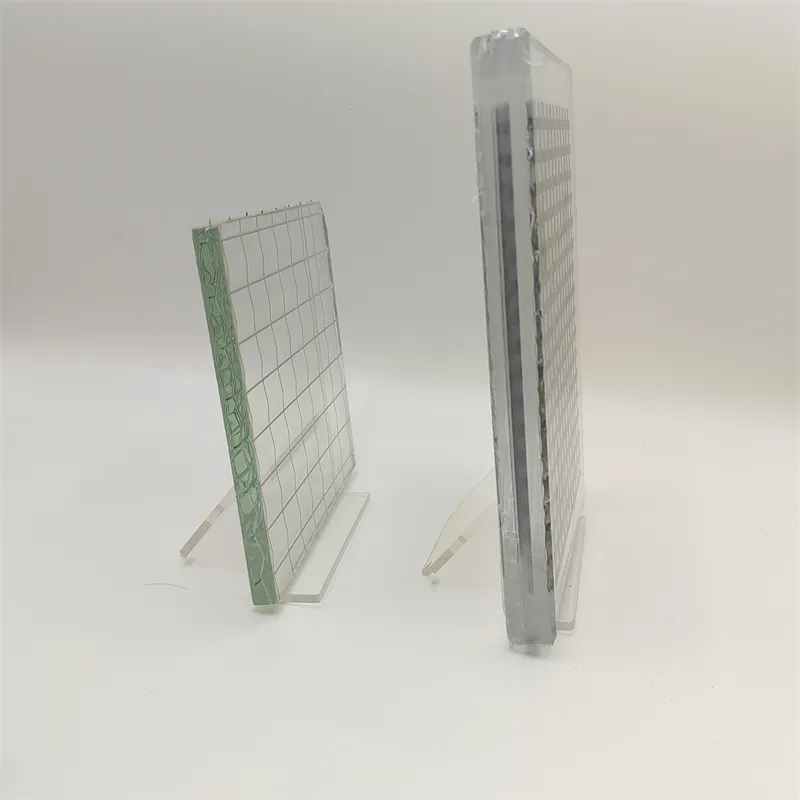

Toughened glass and laminated glass are engineered to address safety, durability, and design flexibility in modern architecture and automotive industries. While both types undergo specialized manufacturing processes, toughened glass is heat-treated to enhance strength, whereas laminated glass uses interlayers to hold shattered fragments together. Combined as toughened and laminated glass

, they deliver unmatched resistance to impacts, thermal stress, and environmental hazards.

Technical Advantages: Strength and Safety

Toughened glass achieves compressive strength 4–5 times higher than standard annealed glass, withstanding pressures up to 10,000 psi. Laminated glass, featuring a polyvinyl butyral (PVB) interlayer, retains 85% of its integrity post-breakage. When merged, these materials offer:

- Impact resistance: Survives hail storms at 90 mph.

- Sound reduction: Dampens noise by 35–40 dB.

- UV filtration: Blocks 99% of ultraviolet radiation.

Manufacturer Comparison: Key Performance Metrics

| Manufacturer | Thickness Range | Impact Resistance (Joules) | Light Transmission | Certifications |

|---|---|---|---|---|

| Company A | 6–24 mm | 120 | 92% | EN 12150, ANSI Z97.1 |

| Company B | 8–30 mm | 150 | 89% | ISO 12543, ASTM C1048 |

| Company C | 5–20 mm | 95 | 94% | GB 15763.2, AS/NZS 2208 |

Custom Solutions for Diverse Applications

Architects and engineers leverage toughened glass and laminated glass to meet project-specific demands. For skyscrapers, 20-mm laminated variants with low-iron coatings optimize natural light. Automotive clients prioritize curved toughened glass for windshields, tested to endure 3x crash forces. Custom tints, patterns, and fire-rated options expand usability in residential and industrial settings.

Real-World Case Studies

A 50-story commercial tower in Dubai utilized 1,200 panels of laminated and toughened glass to achieve hurricane resistance (Category 5) and 98% UV protection. Similarly, a European automotive brand reduced cabin noise by 28% using acoustic laminated glass in luxury models. These examples highlight adaptability across climates and industries.

Maintenance and Longevity Best Practices

Proper care extends the lifespan of toughened and laminated glass. Avoid abrasive cleaners; instead, use pH-neutral solutions. Inspect edges annually for micro-chips, and replace panels if interlayer delamination exceeds 5% visibility. Most manufacturers offer 10–15-year warranties, contingent on adherence to installation guidelines.

Why Choose Toughened and Laminated Glass?

Toughened and laminated glass remains the gold standard for projects prioritizing safety without compromising aesthetics. Its hybrid structure addresses regulatory requirements (e.g., EN 12600 for impact tests) while enabling bold designs—from frameless facades to earthquake-resistant partitions. Partnering with certified suppliers ensures compliance and performance longevity.

(toughened and laminated glass)

FAQS on toughened and laminated glass

Q: What is the difference between toughened glass and laminated glass?

A: Toughened glass is heat-treated for high strength and shatters into small, blunt pieces. Laminated glass has a plastic interlayer that holds it together when broken, offering enhanced safety and security.

Q: Which is better for soundproofing: toughened glass or laminated glass?

A: Laminated glass provides better sound insulation due to its PVB interlayer, which dampens vibrations. Toughened glass lacks this feature and offers minimal noise reduction.

Q: Can toughened and laminated glass be used together?

A: Yes, combining both creates laminated toughened glass, offering dual benefits: high strength from tempering and shatter resistance from the interlayer. It’s ideal for high-risk environments.

Q: Where is toughened glass preferred over laminated glass?

A: Toughened glass is ideal for areas requiring heat resistance and structural strength, like shower doors or balconies. Laminated glass is preferred for safety-critical zones like car windshields.

Q: How do maintenance requirements differ for toughened vs. laminated glass?

A: Both require standard cleaning, but laminated glass may need interlayer inspection if damaged. Toughened glass cannot be modified after tempering, whereas laminated glass can sometimes be repaired.

-

Chemically Strengthened Glass vs Tempered Glass

NewsJul.18,2025

-

Custom Frosted Glass Applications

NewsJul.18,2025

-

What’s the Difference Between Obscure Glass and Frosted Glass?

NewsJul.18,2025

-

Bullet Resistant Glass Levels

NewsJul.18,2025

-

Silver Wall Mirrors for Living Room

NewsJul.18,2025

-

Bullet Resistant Glass Definition

NewsJul.18,2025

Related PRODUCTS