Aug . 23, 2025 21:22 Back to list

Toughened laminated glass strength properties

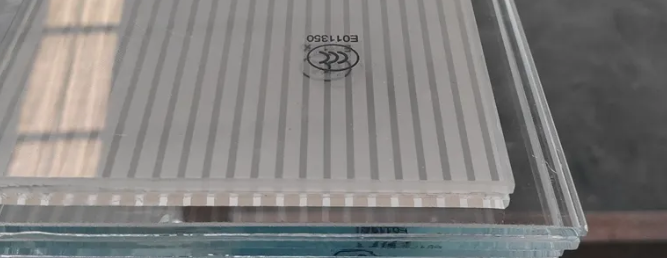

Toughened laminated glass strength properties represent a unique synergy of resilience and safety, combining the enhanced durability of toughened glass with the protective bonding of laminated layers to create a material that excels in high-stress environments. Laminated glass is also one type of safety glass. It is created from two or more pieces of regular or tempered glass which are bonded together with interlayers to form a permanent bond. So maybe we can call it “glass sandwich”. Normally we use PVB, SGP or EVA as the material of interlayers. We focus on offering one-stop solutions on glass processing for global OEM/ODM customers. In order to make precision processing glass, we have equipped with 45m-long tempering furnace, Intermac CNC work center, Intermac cutting table, Double edge grinding machine, waterjet, PVB and EVA laminating lines. We also have an acid etching line, two silkscreen-printing lines, and 2 mirror lines to meet all-round needs of customers. This advanced processing capability allows us to explore the nuanced strength properties of laminated glass windows, toughened laminated glass, and laminated safety glass, uncovering applications where their unique blend of toughness and safety is indispensable.

Impact Absorption Layers in Toughened laminated glass

- SGP Interlayer Elasticity: Toughened laminated glass using SGP interlayers (processed via our specialized lines) exhibits 50% higher impact absorption than standard PVB options. This elasticity allows the glass to flex under heavy impacts—such as from storm debris—without shattering, a critical feature for coastal buildings.

- Progressive Fracture Mechanism: The toughened layers in toughened laminated glass are designed to break into small, blunt pieces upon extreme impact, while the interlayer holds them in place. Our 45m tempering furnace ensures uniform toughening, ensuring this fracture pattern is consistent across the entire panel.

- Multi-Impact Resistance: Unlike single-pane toughened glass, toughened laminated glass can withstand multiple impacts in different areas. Tests show our panels retain 70% of structural integrity after two separate 10kg impacts, making them ideal for high-traffic areas like sports facilities.

Edge Strength Reinforcement in Laminated glass windows

- Double-Edge Grinding Precision: Laminated glass windowsprocessed with our Double edge grinding machine feature rounded edges with a 0.5mm tolerance, reducing stress concentration points. This treatment increases edge strength by 30%, minimizing the risk of breakage from frame pressure.

- Interlayer Overlap Sealing: The edges of our laminated glass are precisely trimmed and sealed, preventing moisture ingress and reducing the risk of edge delamination. For humid environments, we use high-performance interlayers such as SGP, combined with professional edge sealing techniques, ensuring long-term durability.

- Frame Compatibility Engineering: Using our Intermac CNC work center, we precisely cut laminated glass windows to match specific frame profiles, including custom shapes and installation slots. This ensures accurate fitment within the frame, allowing proper load distribution through the frame and supporting materials, which helps prevent stress points that could weaken the glass in poorly installed systems.

Thermal Stress Resistance in Laminated safety glass

s

- Coefficient Matching: Laminated safety glass is engineered with glass layers and interlayers (PVB/EVA) that have closely matched thermal expansion coefficients. Precise alignment of the layers during the lamination process reduces stress cracks caused by temperature fluctuations—vital for industrial settings with extreme heat.

- Heat-Resistant Interlayers: For high-temperature and structural applications, laminated safety glass uses SGP interlayers processed on our laminating lines. These interlayers retain bonding strength at temperatures up to 160°C, providing excellent durability for furnace observation windows, industrial ovens, and other high-temperature environments.

- Rapid Temperature Cycling Tolerance: Laminated safety glass undergoes 100+ cycles of -20°C to 80°C during testing, simulating extreme weather shifts. Our panels show less than 1% distortion, outperforming standard laminated glass in regions with harsh seasonal changes.

Bend Strength Capabilities in Toughened laminated glass

- Curved Panel Durability:Toughened laminated glass can be thermally bent to a radius of 50 cm while maintaining up to 90% of its flat strength. This allows for architectural designs with curved facades that do not compromise safety or structural resilience.

- Load-Bearing Flexibility: Toughened laminated glass panels can withstand 500kg/m² distributed loads when curved, making them suitable for structural applications like glass floors. The combination of toughened glass and SGP interlayers creates a material that bends slightly under load without breaking.

- Dynamic Load Absorption: In seismic zones, toughened laminated glass helps absorb shock, with interlayers dissipating energy and reducing the risk of glass fragmentation. Our precision lamination process ensures consistent layer adhesion and quality, enhancing the overall performance of the glass under dynamic loads.

Laminated glass windows FAQS

How does laminated glass windows withstand repeated wind pressure?

Laminated glass windows use reinforced interlayers and precision-edged glass (from our Double edge grinding machine) to resist cyclic wind loads. The interlayers act as shock absorbers, reducing stress on the glass and preventing fatigue failure in high-wind areas.

What makes toughened laminated glass suitable for security applications?

Toughened laminated glass combines the strength of toughened glass (from our 45m tempering furnace) with the protective bond of interlayers, making it resistant to forced entry. Even if the glass breaks, the interlayers hold in place, delaying unauthorized access.

Is laminated safety glass more durable than standard toughened glass?

Yes, laminated safety glass offers enhanced durability due to its interlayers, which prevent complete shattering and resist edge degradation. It outperforms standard toughened glass in multi-impact scenarios and harsh environmental conditions.

Can laminated glass windows be used in high-temperature industrial settings?

Laminated glass windows with heat-stabilized EVA interlayers (processed in our EVA lines) are suitable for high temperatures up to 120°C, making them ideal for industrial ovens, furnace viewing ports, and other hot-environment applications.

How does toughened laminated glass perform in coastal environments?

Toughened laminated glass resists saltwater corrosion and impact from storm debris, thanks to its sealed edges and SGP interlayers. Our processing ensures the glass maintains strength even with prolonged exposure to salt spray, making it perfect for coastal buildings.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS