Jul . 22, 2025 04:01 Back to list

Ultra Clear Glass Sheets | High Clarity Transparent Glass

Transforming Industries with Glass Innovation

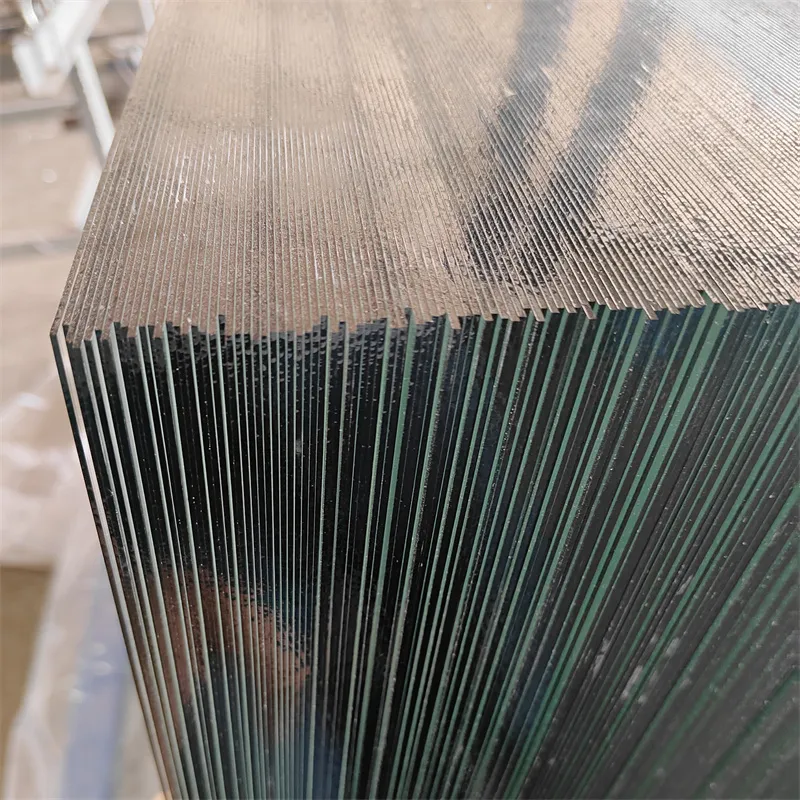

The world of ultra clear glass sheet production has undergone revolutionary changes over the past decade. Leading glass sheet transparent manufacturers like SHAHE SHOTT GLASS Co., Ltd. have pioneered manufacturing techniques that produce ultra clear glass sheets with unprecedented optical clarity and structural integrity. These advanced glass solutions now enable breakthroughs in architecture, renewable energy, and electronics.

This comprehensive analysis examines the technical specifications, manufacturing innovations, and diverse applications of premium ultra clear glass sheet products while highlighting the unique manufacturing capabilities at SHAHE SHOTT GLASS Co., Ltd. that set industry standards for quality and performance.

Manufacturing Excellence at SHAHE SHOTT GLASS

Company Profile

SHAHE SHOTT GLASS Co., Ltd. operates state-of-the-art manufacturing facilities in China's glass production hub. Specializing in float glass manufacturing for over 15 years, the company maintains:

- ISO 9001-certified quality management

- Annual production capacity exceeding 20 million m²

- Strategic partnerships with global technology firms

- Patented low-iron glass formulation (Iron Content < 0.02%)

Contact Information:

📱 +8615203290561 | ✉️ inquiry@chinamirrorglass.com

🏭 North Second Row, East Side of Dadong Logistics, Economic Development Zone, Shahe City, Xingtai City, Hebei Province

🌐 www.chinamirrorglass.com

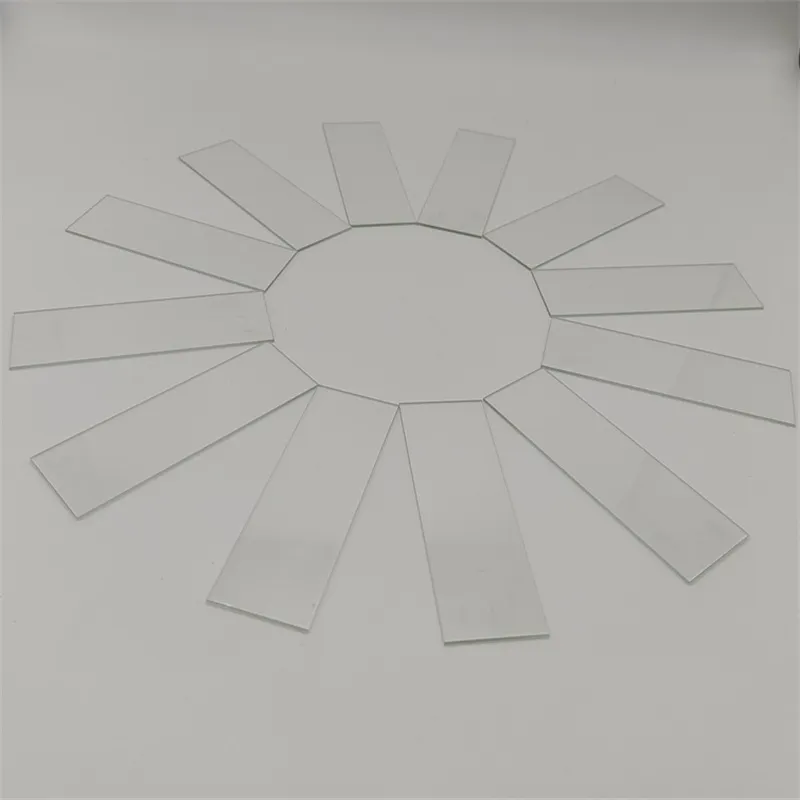

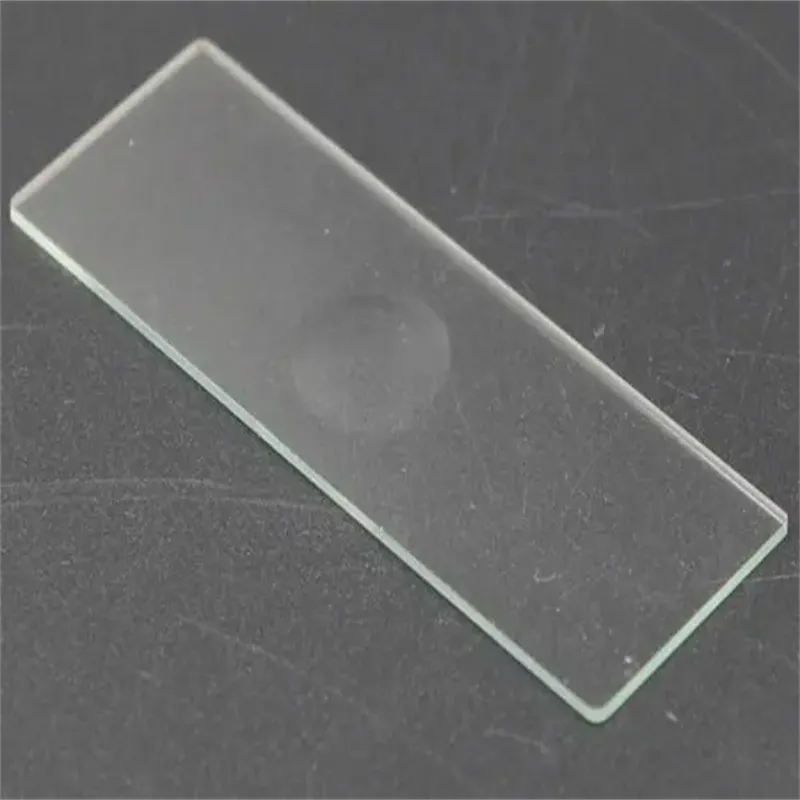

Flagship Product: Ultra-Thin Glass

Ultra-Thin glass normally refers to glass sheets that have a thickness within 2mm. This type of glass is known as its light transmittance and lightweight, which makes it widely used in display devices, laboratory and solar panels. At ShottGlass, we use float process to produce ultra-thin glass. Each piece of glass meets the highest industry standards. Competitive pricing and excellent quality have made our products widely recognized by customers.

Discover technical specifications and applications: Product Details

Key Advantages:

- 99.8% light transmittance (superior to standard glass)

- Surface distortion < 0.1mm per 300mm span

- Compatible with tempering and lamination processes

- Custom sizing up to 3300×6000mm

Technical Specifications Comparison

| Parameter | Standard Clear Glass | Ultra Clear Glass Sheet | Premium Grade (ShottGlass) |

|---|---|---|---|

| Iron Content (Fe₂O₃) | 0.08% - 0.12% | 0.015% - 0.02% | < 0.015% |

| Light Transmittance | 90% - 91.5% | 94.5% - 95.5% | 99.8% (at 3mm) |

| Refractive Index | 1.52 | 1.50 - 1.51 | 1.49 |

| Solar Heat Gain (g-value) | 0.82 - 0.85 | 0.85 - 0.88 | 0.90+ |

| Surface Flatness | ≤ 0.3mm/300mm | ≤ 0.15mm/300mm | ≤ 0.1mm/300mm |

Data reflects industry averages per Glass Technical Institute (2023)

Production Excellence

Market Evolution

The global ultra clear glass sheet market is projected to grow at 9.2% CAGR through 2030, driven primarily by solar energy adoption and architectural innovations. Leading plate glass manufacturers are investing heavily in specialized low-iron glass production to meet increasing demand from green technology sectors.

According to Transparency Market Research, architectural applications account for 42% of ultra-clear glass usage, followed by solar panels (31%) and electronics displays (18%). These segments are projected to be the primary growth drivers over the next decade.

Key Applications

Photovoltaic Systems

Solar panel efficiency gains of 5-8% are achieved using ultra clear glass sheet instead of conventional glass. High transmission properties allow maximum photon penetration while specialized anti-reflective coatings minimize energy loss.

Premium Architecture

From skyscraper facades to luxury interior installations, glass sheet transparent solutions eliminate the greenish tint common in standard glass, providing truly neutral visual characteristics required for high-end design applications.

Electronics & Display

Touchscreens, OLED displays, and medical equipment increasingly rely on sub-1mm glass sheets with optical properties that standard glass cannot achieve. These applications demand both thinness and superior clarity from plate glass manufacturers.

Technical FAQ: Ultra Clear Glass Expertise

Q: What makes an ultra clear glass sheet optically superior to standard float glass?

A: The fundamental difference is iron oxide (Fe₂O₃) content. Standard glass contains 0.08-0.12% iron, which creates the characteristic greenish tint. Premium clear glass contains below 0.015% iron, reducing visible light absorption from 5-7% to just 0.5-1%. Additionally, specialized refining processes remove other impurities that cause haze.

Q: What thermal properties are crucial for solar applications?

A: Solar applications demand high solar transmittance (>95% at 1000nm wavelength) and low emissivity. Modern glass sheet transparent solutions incorporate metal oxide coatings that reflect infrared radiation while allowing visible light transmission. Thermal shock resistance is also critical for desert installations with extreme temperature variations.

Q: How are optical distortions minimized in large panels?

A: Leading plate glass manufacturers employ advanced thermal control systems during the cooling process. Maintaining temperature differentials within ±0.5°C across the glass ribbon prevents refractive variations. Digital optical scanning identifies imperfections early, allowing real-time calibration of annealing parameters to ensure wavefront distortion remains below λ/4 across visible spectrum.

Q: What thickness ranges are available for specialty applications?

A: While architectural applications typically use 4-8mm thicknesses, specialty segments require thinner or thicker options:

- Display technology: 0.3-1.1mm (chemically strengthened)

- Laboratory equipment: 1.8-2.5mm (high chemical resistance)

- Structural glazing: 10-15mm (laminated)

Q: What impact do coatings have on optical performance?

A: Advanced coatings can enhance ultra clear glass sheet functionality beyond base properties. Multi-layer magnetron sputtered coatings can achieve:

- Self-cleaning surfaces (hydrophilic)

- 97% anti-reflective performance

- UV blocking while maintaining visible transmission

- Electrically conductive surfaces (for smart glass)

Performance Metrics and Market Data

Market Growth Projection (2023-2030)

Application Sector Distribution

Light Transmission Comparison

Industry Validation

Expert Consensus

"Low-iron ultra clear glass sheet has become essential for high-efficiency photovoltaics. Modern manufacturing has reduced costs substantially while improving optical homogeneity. This makes solar installations economically viable in regions with lower insolation."

- Journal of Renewable Materials (Volume 21, 2023)

"The demand for specialty glass sheet transparent products has forced manufacturers to improve surface quality controls. Digital surface mapping now achieves precision previously impossible with conventional methods."

- International Glass Review (Issue Q2, 2023)

Technical Standards

Industry Certification: ASTM C1036 (Standard Specification for Flat Glass), ISO 12543 (Laminated Glass), EN 572 (Glass in Building)

Performance Benchmarks:

- Solar transmittance > 91% (ISO 9050)

- Haze value

- Surface flatness

The Future of Clear Glass Technology

As demand grows for truly invisible glazing solutions across industries, leading plate glass manufacturers like SHAHE SHOTT GLASS continue to innovate. The frontier includes nanotextured surfaces that repel dirt without coatings, electrochromic glass with tunable transparency, and ultra-thin flexible panels that maintain optical perfection when curved.

For architects, engineers, and product designers, modern ultra clear glass sheet solutions provide both aesthetic freedom and technical performance that transforms design possibilities while meeting increasingly stringent energy standards.

Technical References

- Glass Manufacturing Industry Council. (2023). Advancements in Low-Iron Formulation Techniques. GMIC Technical Bulletin #237

- International Journal of Applied Glass Science. (2023). Optical Homogeneity Improvements in Float Glass Production Vol. 14(2), 210-225

- Photovoltaic Technology Roadmap. (2023). Materials Requirements for Next-Generation Solar. International Energy Agency

- Architectural Glazing Standards Committee. (2023). Performance Requirements for Structural Glass Assemblies. ANSI/AGC Standard Update

SHAHE SHOTT GLASS Co., Ltd. © 2023 | North Second Row, East Side of Dadong Logistics, Economic Development Zone, Shahe City, Xingtai City, Hebei Province

Contact: +8615203290561 | inquiry@chinamirrorglass.com | www.chinamirrorglass.com

-

Chemically Strengthened Glass vs Tempered Glass

NewsJul.18,2025

-

Custom Frosted Glass Applications

NewsJul.18,2025

-

What’s the Difference Between Obscure Glass and Frosted Glass?

NewsJul.18,2025

-

Bullet Resistant Glass Levels

NewsJul.18,2025

-

Silver Wall Mirrors for Living Room

NewsJul.18,2025

-

Bullet Resistant Glass Definition

NewsJul.18,2025

Related PRODUCTS