Jan . 13, 2025 16:19 Back to list

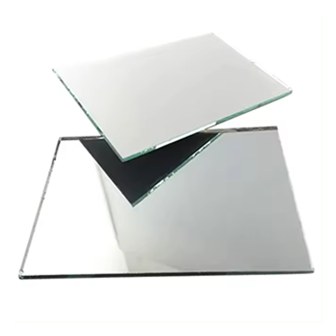

Ultra-Thin Glass

Transparent glass sheets have revolutionized both architectural design and interior aesthetics with their unique blend of functionality and style. These versatile materials are not just simple panes of glass; they are crafted to optimized precision, serving a multitude of purposes in modern construction and design while enhancing light and space in innovative ways.

In terms of durability and safety, today's transparent glass sheets are engineered to meet high standards. Through processes such as tempering and lamination, these sheets attain increased strength and resilience. Laminated glass, for example, incorporates a polyvinyl butyral (PVB) interlayer, which holds the glass together upon impact, reducing the risk of injury—a critical factor when considering applications in high-traffic areas or at elevated heights. This engineered strength also means that transparent glass sheets are not susceptible to discoloration or corrosion, maintaining their pristine look over time—even in harsh environmental conditions. The authority of transparent glass in modern construction cannot be overstated. Industry leaders continually develop new variations, such as anti-reflective coatings or self-cleaning surfaces, to push the boundaries of what transparent glass can achieve. These innovations are backed by rigorous testing and international certifications, ensuring both quality and performance. For professionals and enthusiasts alike, understanding the full potential and applications of transparent glass sheets can transform approaches to design and construction. Their ability to create visually stunning and functional spaces emphasizes their importance in the toolkit of modern builders and designers, promoting a seamless blend of nature and technology in everyday structures.

In terms of durability and safety, today's transparent glass sheets are engineered to meet high standards. Through processes such as tempering and lamination, these sheets attain increased strength and resilience. Laminated glass, for example, incorporates a polyvinyl butyral (PVB) interlayer, which holds the glass together upon impact, reducing the risk of injury—a critical factor when considering applications in high-traffic areas or at elevated heights. This engineered strength also means that transparent glass sheets are not susceptible to discoloration or corrosion, maintaining their pristine look over time—even in harsh environmental conditions. The authority of transparent glass in modern construction cannot be overstated. Industry leaders continually develop new variations, such as anti-reflective coatings or self-cleaning surfaces, to push the boundaries of what transparent glass can achieve. These innovations are backed by rigorous testing and international certifications, ensuring both quality and performance. For professionals and enthusiasts alike, understanding the full potential and applications of transparent glass sheets can transform approaches to design and construction. Their ability to create visually stunning and functional spaces emphasizes their importance in the toolkit of modern builders and designers, promoting a seamless blend of nature and technology in everyday structures.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS