Jun . 24, 2025 14:30 Back to list

Premium Float Glass Line for Modern Architecture

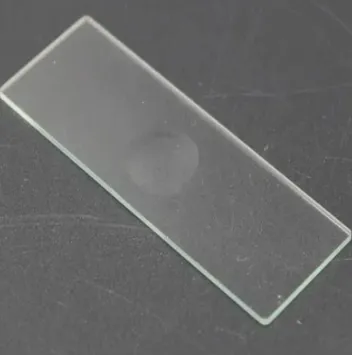

As construction and design industries continue to evolve, so does the demand for clarity, strength, and innovation in building materials. At the forefront of this movement is ShottGlass, a renowned float glass supplier now offering a refreshed selection of premium float glass for sale designed to meet the demands of both large-scale architectural projects and interior design applications.

What Makes Float Glass Stand Out from the Rest?

At the heart of the production process, float glass is created using a meticulous method involving high temperatures and a bath of molten tin. The main raw materials include silica sand, soda ash, limestone, and dolomite. These ingredients are melted together at about 1,500°C, then allowed to "float" over a bed of molten tin. This produces a smooth, uniformly thick sheet with exceptional optical clarity.

What separates float glass from older styles such as lattice or "pull method" glass is this very process. Lattice glass, formed by drawing molten glass upward through rollers, often results in waves and surface inconsistencies. In contrast, clear float glass produced through the float process is flawless in transparency, perfectly flat, and highly versatile.

This consistency makes float glass an ideal material for windows, partitions, facades, and even mirrors. Its widespread adoption is no coincidence—ShottGlass continues to meet high demands by supplying both annealed float glass and custom-cut options with outstanding clarity and strength.

Exploring the Benefits of ShottGlass Clear Float Glass

ShottGlass’s line of clear float glass is widely praised for its high light transmittance, minimal distortion, and ease of processing. Architects and interior designers especially appreciate the visual purity it offers when used for transparent or semi-transparent installations.

One of the standout benefits of clear float glass is its adaptability. It can be tempered for added strength, laminated for security, or coated for energy efficiency. Its resistance to scratches and environmental corrosion also makes it a reliable long-term solution for both exterior and interior use.

Moreover, ShottGlass emphasizes environmental responsibility in its production line. The materials used are non-toxic and recyclable, and the float process itself minimizes energy waste. This commitment to sustainable manufacturing places the company at the top of any list when choosing a float glass supplier.

Why Choose Annealed Float Glass for Structural and Decorative Projects

ShottGlass also offers annealed float glass, an essential material where precision and stability matter. Unlike tempered glass, which shatters into small fragments, annealed float glass breaks into large, manageable pieces, making it easier to handle during custom shaping and post-processing.

Clients prefer annealed float glass in applications that require further cutting, edging, or drilling. The uniform molecular structure ensures it won’t warp or distort during these operations. It also forms the base product for more advanced processing, such as tempering and lamination.

This makes annealed float glass ideal for interior panels, display cases, and decorative partitions. With ShottGlass’s capacity to fulfill bulk orders, companies seeking float glass for sale can rest assured they are sourcing from a partner that combines technical excellence with reliable delivery timelines.

ShottGlass: Your Trusted Float Glass Supplier

The reputation of ShottGlass as a trusted float glass supplier comes from its unrelenting focus on customer satisfaction and industry leadership. From precise dimensional control to custom finishes, every sheet of float glass is manufactured to meet stringent global standards.

In addition to bulk float glass for sale, ShottGlass provides personalized consultation services to help clients select the best product for their project—be it clear float glass for office buildings or annealed float glass for interior décor. The company also ensures that its shipping practices preserve the pristine condition of each product upon delivery.

With extensive inventory, technical support, and decades of expertise, ShottGlass continues to be the go-to float glass supplier for contractors, architects, and retailers alike.

Float Glass FAQs

What are the main components used in making float glass?

Float glass is made primarily from silica sand, soda ash, limestone, and dolomite, which are melted and floated on molten tin to form a smooth sheet.

How is float glass different from lattice glass (pull method)?

Unlike lattice glass, which may have surface inconsistencies due to the upward drawing process, float glass is perfectly flat and clear because it is floated over molten tin during formation.

What advantages does annealed float glass offer?

Annealed float glass is stable and easy to cut, drill, or process. It’s ideal for use in applications where additional shaping is needed before tempering or lamination.

Can I order customized sizes or thicknesses of clear float glass?

Yes, ShottGlass offers custom-cut services for clear float glass, allowing clients to choose dimensions, thickness, and edge treatments to suit specific project needs.

Why choose ShottGlass as your float glass supplier?

ShottGlass provides high-quality float glass for sale with competitive pricing, reliable delivery, and expert support, making them a trusted partner in the architectural glass market.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS