Your reliable glass fabrication supplier

We focus on offering one-stop solutions on glass processing for global OEM/ODM customers.

In order to make precision processing glass, we have equipped with a 45m-long tempering furnace, Intermac CNC work center, Intermac cutting table, Double edge grinding machine, waterjet, PVB, and EVA laminating lines. We also have an acid etching line, two silkscreen- printing lines, and 2 mirror lines to meet the all-round needs of customers.

Several Processing

We have built up two automatic cutting lines. The Intermac Cutting Table supports the maximum precision and minimum cutting tolerance. Accurate cutting is the priority of all the further glass and mirror processing.

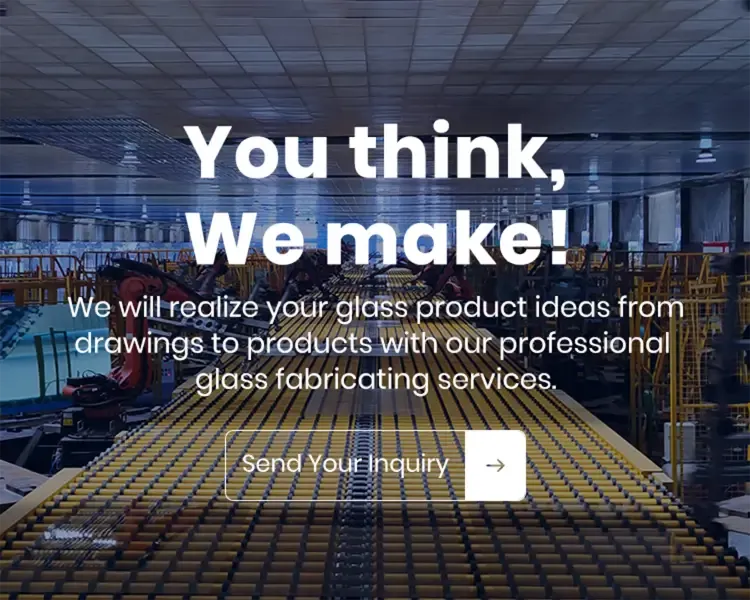

To give our customer the glass of best edging quality and precision, we set 6 cnc work centers to grind edges and corners on different kind of glass and mirror. Min workable size is 250*200mm and max workable size is 3660*2500mm, tolerance +-0.5mm, 1.6mm-19mm thickness.

Colorful logo and graphics can be printed on glass and mirror products by our silk screen printing line and UV-printer. Skilled engineers can give you solutions regarding glass pattern design, and anti-UV ink.

We set up 2 lines of double edging grinding line to combine accuracy and efficiency. Workable on C-edge and flat-edge, range 65mm-3100mm, matte and polished.

Glass tempering furnace can produce half tempered glass 1.3mm-19mm, and fully tempered glass 3mm-19mm. Everyday capacity is 5000sqm.

Irregular holes and ultra thick glass can not be processed with general cutting table. We set up 3 waterjet cutting lines to make custom glass holes. The advantage is that Waterjet finish does not need further processing before tempering.

We have 8 acid reacting pool for matte glass, ag glass, and acid etched glass. The horizontal producing line max processing size is 2850*4200mm, and vertical pool max glass processing size is 2000*2800.

-

28 Years of Glass Fabricating History

28 Years of Glass Fabricating HistoryOur history started since 1996, from a family-owned factory to a global target company.

-

3 Plants of 20000sqm

3 Plants of 20000sqm3 plants of total 20000sqm workshop enables us to do all glass processing including precision processing, acid surface processing, and mirror fabricating.

-

Experienced Team

Experienced TeamWe have developed an experienced team 24hour ready to make your designing to real products and give you whole process services.

-

Certifications

CertificationsOur tempered glass panel products surpass requirements of GB15763.2-2005, and LED Mirror is FCC certified with UL certified components. Pattern glass is certified by CMA&CNAS.

You Think, We Make

-

learn more

learn moreFloat glass, a type of flat glass produced through the "float" process, is known for its uniform thickness and smooth flatness. Its outstanding properties make it the most widely used base material in the glass industry.

-

learn more

learn moreLED mirrors are mirrors with LED lights built into or surrounding them. They are a type of illuminated mirror, known for energy efficiency, long lifespan, and the ability to produce a range of color temperatures. As technology advances, its styles and functions have become increasingly diverse. Not only has the appearance of the mirror become more attractive, but its practical features also make it convenient for people to apply makeup or take a bath. LED mirrors are commonly used in bathrooms and often serve as vanity mirrors with lights in bedrooms or living rooms.

-

learn more

learn moreIn contemporary society, shower room is an element that must be considered in our bathroom design. A suitable shower room not only brings a lot of convenience to our lives, but also affects the style and beauty of the entire room. Whether in residential buildings or commercial hotels, a clean and tidy shower room is an indispensable bathroom facility. As a leading shower room manufacturer in China, ShottGlass specializes in the design and manufacture of shower rooms and can provide you with a shower room design solution based on the size and layout of your bathroom.

-

learn more

learn moreAnti-reflective glass (AR glass) is a kind of coated glass with great light transmission and reflection control properties. It is normally produced by coating on one or both surfaces of float glass with an advanced magnetron sputtering technology. Using low-iron glass as the base glass to make anti-reflective glass will achieve a better effect.

-

learn more

learn moreGlass panels are a type of glass unit, made from flat or plate glass using various processing techniques. Known for their excellent advantages, including great functionality, a gorgeous finish, and cost-effectiveness, glass panels have become one of the most popular materials in modern construction, interior decoration, and the automotive industry. As glass manufacturing technology continues to improve, glass panels will gain more functions, enabling their use in various new fields that have not yet been fully developed.

-

learn more

learn moreCopper-free mirror is a greatly improved version of silver mirrors. As we all know, during the production process of ordinary silver mirrors, after the reflective layer of silver is coated, a copper layer will be coated on top of the silver layer to protect the silver layer, and then spraying twice back paint as the last protection layer of the mirror. However, in the processing of copper-free silver mirrors, the copper layer is replaced by a more environmentally friendly material. Therefore, copper-free silver mirror is also called environmentally friendly mirror.

-

learn more

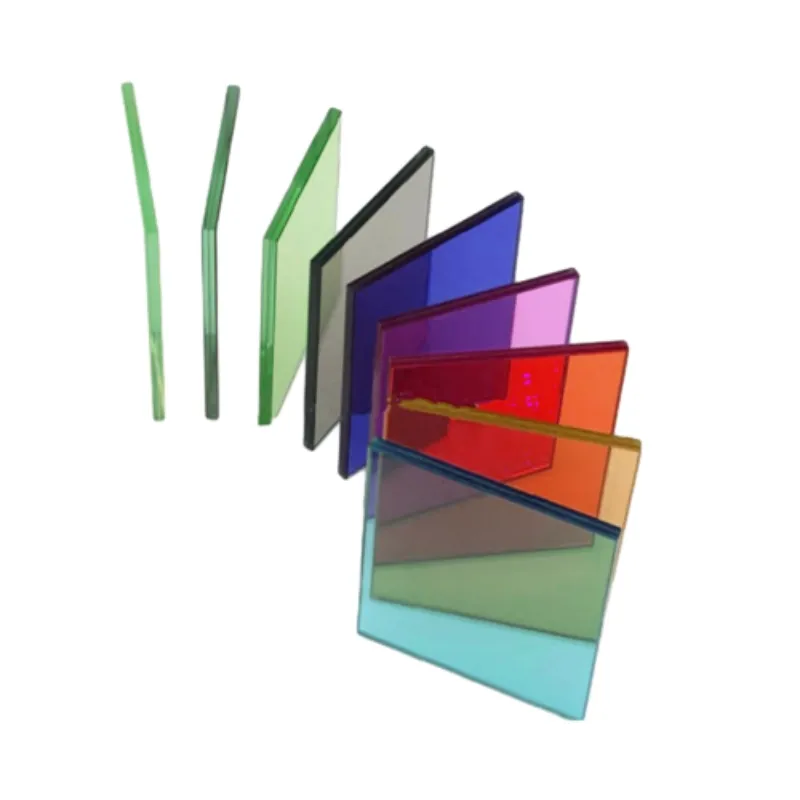

learn moreTinted glass is a kind of colored glass which is made by adding some specific colorants to the ordinary clear glass during the manufacturing process. This makes regular glass appear a different color and creates an effect of sunlight absorbing. We normally supply five main tone of tinted glass, including bronze, grey, black, green, blue. And there are also some extend tone to our products, such as Golden bronze, Euro bronze, Dark grey, Dark green, F-green, F-blue, Ocean blue.

-

learn more

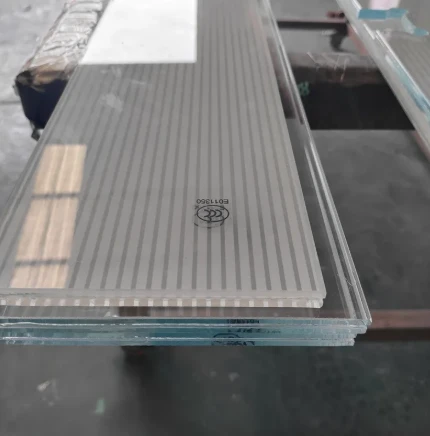

learn morePatterned glass is one type of obscure glass, also known as textured glass, it is a kind of flat glass made by rolling method. Before the glass is hardened, a patterned roller is used to emboss patterns on one or both surface of the glass. This kind of glass can obscure a certain amount of sight and at the same time has good light transmission. Due to this feature, it is mainly used in indoor partitions, door and window glass, bathroom glass partitions, etc.

How we ensure every

piece of glass is masterpiece?

We control the quality of the raw material. Every piece of glass will be carefully checked by an online AI computer before processing. During the processing in our factory, our staff will not allow any B-grade glass out of our quality control system. If our customer receives glass products with any mistake, we will 100% refund without any trouble.

- 1Is your company a factory or a trading company?Shottglass is a glass manufacturer group. We have our own workshop and production equipment. we focus on the production and sales of building glass, decoration glass, and solar glass for many years.

- 2How do you control the quality of your products in the processing?This is a good question. We will arrange for the quality manager to monitor the whole production process from the first piece to the last piece. Thus, we can provide the best quality to our customers.

- 3I only need a small quantity of products, can you produce for us?We attach importance to every customer’s requirement and we will try our best to meet your needs, even it is a small order.

- 4If I can't find the required product on your website, what should we do?That is not a concerned issue. We can provide custom service for you, just give us your sample or tell us your ideas.

- 5What about the lead time?Considering the different products have different production processing, the general production lead time will be from 1 week to 3 weeks. If your product is a custom one, maybe it needs more than a week to match your design.

- 6Can I customize the size of my glass products?Most of the size is available in our factory, and we will cut it based on the size that you have provided to us.

- 7If I received the broken goods or some pieces of the glass cracked, what should I do?Just inform us and provide a picture of the broken goods, and we will pay for your lost after we confirm it.

- 8What are your payment terms?30% deposit before production and the balance payment before shipment.

Still need help for any problem?

Check out our In-App Help, Blog and Youtube Channel. You can also email our support team;at

david@chinamirrorglass.com

Request An Instant Quote?

We have a strong and efficient team that can offer you an instant and professional quote.

Our product manager will give you a quick demand portrait according to your design, drawing, standard, testing methods, and other requirements. And we have a strong supporting team to fulfill your demand with our deep technology and know-how base. We can offer you a solution or a few options. And you will decide which one you prefer.

Latest Insight, Top News Headlines.

-

24Jun

24JunSafety and Style with Premium Laminated Glass Solutions

ShottGlass continues to set the industry benchmark with its high-quality laminated glass offerings, serving customers worldwide who demand superior performance, elegant design, and unmatched safety.

learn more -

24Jun

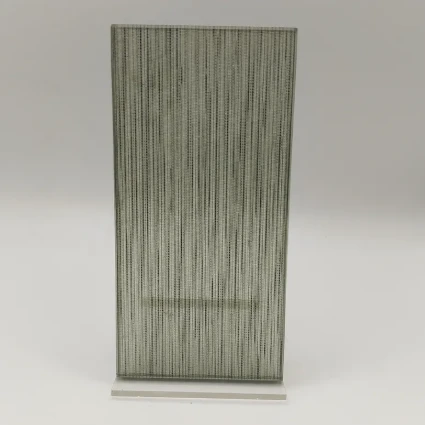

24JunReinvents Security with Premium Wired Glass

In today’s high-security environments, safety and transparency must go hand in hand.

learn more -

24Jun

24JunPremium Float Glass Line for Modern Architecture

As construction and design industries continue to evolve, so does the demand for clarity, strength, and innovation in building materials.

learn more