Nov . 06, 2024 07:41 Back to list

Exploring the Benefits and Uses of 10.38% Laminated Glass in Modern Applications

The Revolution of Laminated Glass An Insight into 10.38% Laminated Glass

In the world of construction and design, materials play a crucial role in defining not just the aesthetics but also the functionality and safety of structures. One such remarkable material that has transformed modern architecture is laminated glass. Among the various specifications of laminated glass, the variant with a thickness of 10.38% has gained attention for its unique properties and applications. This article delves into the intricacies of 10.38% laminated glass, its manufacturing process, benefits, and diverse applications.

Understanding Laminated Glass

Laminated glass is created by bonding two or more layers of glass together with an interlayer, typically made of polyvinyl butyral (PVB) or ethylene vinyl acetate (EVA). This combination not only enhances the glass's structural integrity but also provides increased safety features. When broken, laminated glass holds together thanks to the interlayer, preventing shards from scattering and reducing the risk of injury. The interlayer also offers sound insulation and ultraviolet (UV) protection, making laminated glass an ideal choice for a variety of applications.

The Specifications of 10.38% Laminated Glass

The designation of 10.38% laminated glass refers to the thickness of the glass and interlayer combined, which is approximately 10.38 millimeters. This thickness strikes a perfect balance between robustness and weight, making it suitable for several architectural and functional requirements. The composition of 10.38% laminated glass typically involves layers of glass that meet specific industry standards for safety and performance.

The structural benefits of this specific thickness include increased resistance to impacts, better sound insulation, and enhanced thermal performance. 10.38% laminated glass also offers a higher level of protection against forced entry, making it a popular choice in residential, commercial, and security applications.

Manufacturing Process

The production of 10.38% laminated glass involves a meticulous process. The first step is selecting the right quality of glass, which meets the necessary strength and clarity specifications. Following this, the glass sheets are cleaned thoroughly to remove any impurities.

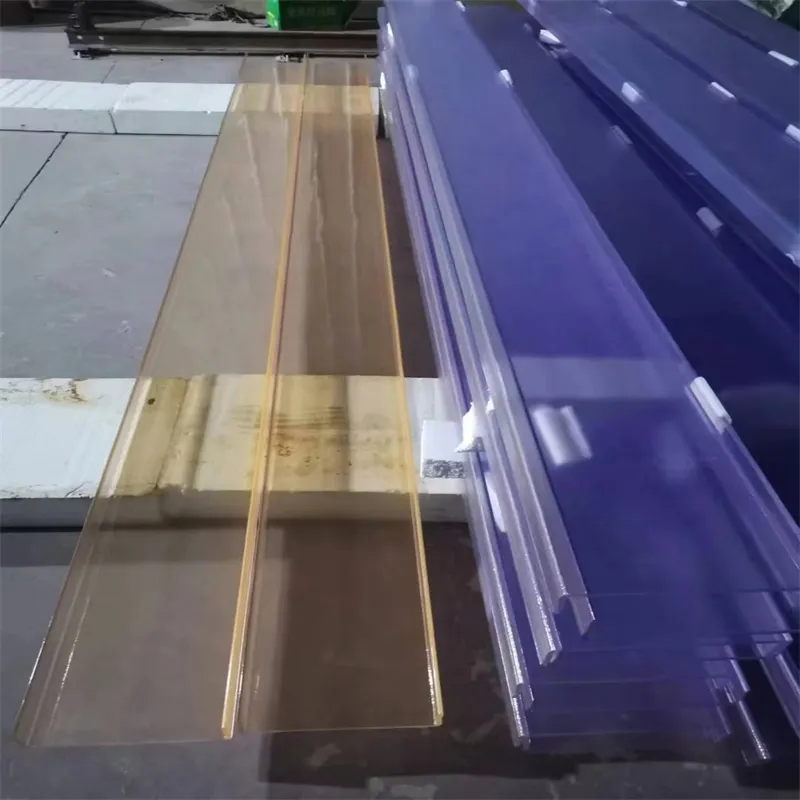

10.38 laminated glass

Next, the PVB or EVA interlayer is placed between the glass layers. The assembly is then subjected to a vacuum and heated in an autoclave, a specialized oven that applies both heat and pressure. This process ensures that the interlayer bonds securely to the glass, resulting in a transparent and durable product.

Advantages of 10.38% Laminated Glass

One of the primary benefits of 10.38% laminated glass is its safety feature. In the event of breakage, the interlayer keeps the glass intact, minimizing the risk of injury. This property makes it an ideal choice for locations prone to vandalism or natural disasters.

In addition, 10.38% laminated glass offers exceptional sound insulation, making it suitable for urban environments where noise pollution is prevalent. The interlayer effectively dampens sound transmission, providing a quieter and more comfortable indoor environment.

Furthermore, laminated glass provides excellent UV protection, blocking harmful rays that can fade furnishings and affect the health of occupants. This protects not only the interiors but also the people who inhabit these spaces.

Diverse Applications

The versatility of 10.38% laminated glass allows it to be used in numerous applications. In residential settings, it is commonly used in windows, sliding doors, and skylights to enhance security and energy efficiency. In commercial constructions, you will find it in storefronts, office partitions, and curtain walls, all of which benefit from its combination of strength and aesthetics.

The security sector also heavily relies on laminated glass. Banks, jewelry stores, and other high-value establishments utilize this material to safeguard against break-ins and robberies.

In conclusion, 10.38% laminated glass represents a significant advancement in glass technology, combining safety, aesthetics, and functionality. Its diverse applications, coupled with its numerous benefits, make it a preferred choice in modern architecture and design. As the demand for versatile, resilient, and safe building materials continues to grow, laminated glass will undoubtedly remain at the forefront of architectural innovation.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS