Nov . 30, 2024 06:47 Back to list

2mm Clear Float Glass for Durable and Stylish Applications in Modern Design

Understanding 2mm Clear Float Glass Properties, Uses, and Applications

Glass has been a vital material in architecture, manufacturing, and design for centuries, cherished for its versatility, aesthetic appeal, and functional properties. Among the various types of glass available in the market, 2mm clear float glass stands out due to its unique characteristics and a plethora of applications. This article delves into the properties, manufacturing process, and diverse uses of 2mm clear float glass.

Properties of 2mm Clear Float Glass

2mm clear float glass is characterized by its remarkable clarity and thin profile. With a thickness of just 2mm, it is lightweight yet sturdy enough to serve multiple functions in both domestic and commercial settings. The glass is produced by a process known as the float glass method, which ensures a smooth and uniform surface. This method involves floating molten glass on top of molten tin, resulting in a flawless product devoid of impurities.

The transparency of this glass allows for high optical clarity, making it an ideal choice for applications where visibility is crucial. Even at a thickness of only 2mm, it maintains a level of durability, although it is worth noting that its thinner profile may make it more susceptible to breakage compared to thicker glass variants.

Manufacturing Process

The manufacturing of 2mm clear float glass is a technical and highly controlled process. It begins with the melting of raw materials, which typically include silica sand, soda ash, and limestone at temperatures exceeding 1,600 degrees Celsius. Once melted, the molten glass is pushed onto a layer of molten tin, where it spreads out due to gravity, creating a smooth surface as it cools. This method not only ensures the flatness of the glass but also minimizes the inclusion of air bubbles and other imperfections.

Following this process, the glass is annealed—slowly cooled to relieve internal stresses—before it is cut into sheets of various sizes. The result is a high-quality, clear glass that meets rigorous industry standards.

Applications of 2mm Clear Float Glass

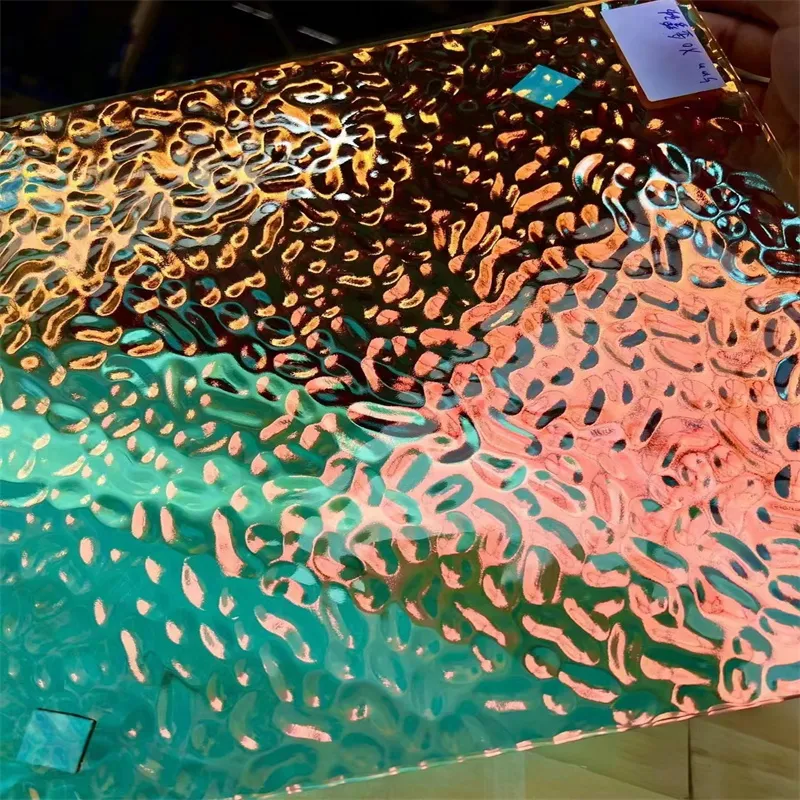

2mm clear float glass

The versatility of 2mm clear float glass makes it suitable for a wide range of applications. Its primary uses include

1. Windows and Glazing Due to its clarity and aesthetic appeal, 2mm clear float glass is frequently used in residential and commercial windows. It offers excellent light transmission while providing a barrier against external elements.

2. Picture Frames The glass's transparency makes it a perfect choice for picture frames, allowing artwork and photographs to be displayed without distortion, ensuring that colors and details are vividly presented.

3. Display Cases Retailers often utilize 2mm clear float glass for display cases. Its lightweight nature allows for ease in handling while offering an unobstructed view of merchandise, thereby enhancing customer engagement.

4. Mirrors This type of glass can be used in the manufacture of mirrors. When coated with a reflective material on one side, 2mm float glass provides an effective and stylish solution for various interior decor needs.

5. Shelving Thinner sheets of glass like the 2mm variant are popular for shelving solutions, particularly in lightweight applications where strength is not the primary concern.

6. Decorative Uses 2mm clear float glass is also favored in artistic applications, including stained glass artworks and installations, where light interaction enhances the overall aesthetic.

Conclusion

In summary, 2mm clear float glass is a remarkable material that combines functionality with elegance. Its clarity, lightweight nature, and ease of manufacturing make it a suitable choice for a myriad of applications, ranging from architectural to artistic uses. While it may not offer the strength of thicker glass variants, its advantageous properties ensure its continued popularity in various industries. As technology progresses, we can expect innovations in glass production and treatment to expand the possibilities for this essential material even further.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS