Jan . 13, 2025 11:24 Back to list

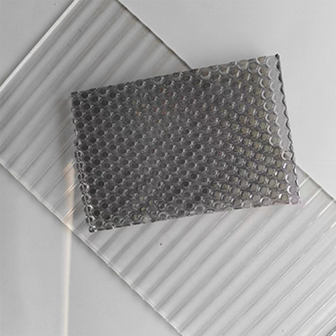

2mm float glass cut to size

Finding the perfect 2mm float glass cut to size can be a game-changer for numerous projects, whether you're embarking on a custom window installation, crafting unique interior designs, or launching a specialized construction project. Customers often seek not just any glass but glass that epitomizes quality, precision, and efficiency. Herein lies a comprehensive guide that underscores the significance of 2mm float glass and why selecting it, cut to precise specifications, can elevate your project to new heights.

An often underscored benefit of 2mm float glass is its cost-efficiency. Due to its reduced thickness, it typically comes with lower production and transport costs, making it a budget-friendly option for both large-scale developments and small bespoke projects. Customers searching for eco-friendly solutions will appreciate that less material use corresponds to a reduced environmental footprint, aligning with sustainable building practices that are increasingly prioritized in today’s market. Trustworthiness in the supply of 2mm float glass is equally crucial. Working with reputable suppliers ensures that the glass is sourced ethically and that it meets the industry's stringent quality controls. It's advisable to seek suppliers who offer transparent certifications and warranties, providing peace of mind that the product not only meets but surpasses safety and performance standards. In summary, the pursuit of 2mm float glass cut to size demands a blend of expert knowledge, precise execution, and trust in your supply chain. By prioritizing these elements, you not only enhance your project's outcome but also contribute to a culture of excellence and sustainability in the use of glass materials. Let this guide be your touchstone in navigating the myriad possibilities that 2mm float glass offers, ensuring that every project is a masterpiece of clarity and strength.

An often underscored benefit of 2mm float glass is its cost-efficiency. Due to its reduced thickness, it typically comes with lower production and transport costs, making it a budget-friendly option for both large-scale developments and small bespoke projects. Customers searching for eco-friendly solutions will appreciate that less material use corresponds to a reduced environmental footprint, aligning with sustainable building practices that are increasingly prioritized in today’s market. Trustworthiness in the supply of 2mm float glass is equally crucial. Working with reputable suppliers ensures that the glass is sourced ethically and that it meets the industry's stringent quality controls. It's advisable to seek suppliers who offer transparent certifications and warranties, providing peace of mind that the product not only meets but surpasses safety and performance standards. In summary, the pursuit of 2mm float glass cut to size demands a blend of expert knowledge, precise execution, and trust in your supply chain. By prioritizing these elements, you not only enhance your project's outcome but also contribute to a culture of excellence and sustainability in the use of glass materials. Let this guide be your touchstone in navigating the myriad possibilities that 2mm float glass offers, ensuring that every project is a masterpiece of clarity and strength.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS