Jan . 21, 2025 02:22 Back to list

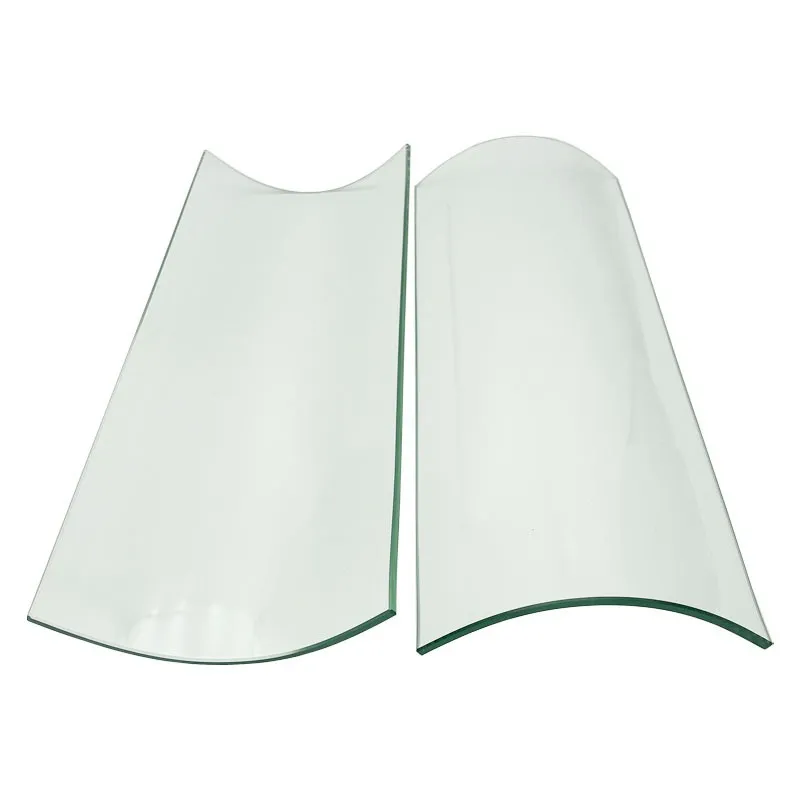

frosted glass partitions

Discovering the Landscape of 4mm Frosted Glass Pricing - An Expert's Guide

Prices for building materials, including 4mm frosted glass, can differ significantly from one region to another, influenced by local market conditions, import tariffs, and demand levels. Areas with robust construction activities or high real estate turnover might experience greater demand, pushing prices upward. Evaluating local pricing trends versus global averages can provide buyers with a comprehensive understanding of what to expect. 4. Application Demands and Customization Usage requirements and customization options notably impact the pricing. Custom sizes, shapes, or designs typically come at a premium. A standard 4mm frosted glass sheet might be less expensive than a bespoke piece crafted for a specific architectural application. Furthermore, commercial projects could favor bulk purchases, leveraging discounts that individuals or small-scale buyers might not access. 5. Environmental Considerations and Quality Assurance With increasing attention on sustainable materials, eco-friendly production methods can affect pricing. Consumers might be willing to pay a premium for glass that is produced with reduced environmental impact. Additionally, quality certifications, warranty provisions, and after-sales services contribute to a perceived value that justifies cost. Customers are often drawn to reliable products, trusting manufacturers who demonstrate authoritative compliance with recognized industry standards. 6. Real-World Insight and Recommendations Research and first-hand experience signify that purchasing decisions should not rely solely on price. Buyers are advised to consider supplier reputability, product durability, and experiential quality. Engage with vendors to understand the support they offer, and request samples or testimonials which can speak volumes of the practical performance of 4mm frosted glass in expected conditions. In conclusion, the pricing structure of 4mm frosted glass is a multifaceted topic—intricately linked with production cost, distribution, market demand, and customization needs. By considering these dimensions, potential buyers can make informed decisions aligned with both budgetary constraints and project requirements, ensuring that they acquire the highest quality glass suitable for their needs. With the guidance of seasoned industry professionals and awareness of market nuances, the perfect balance between cost and value can be achieved, reflecting both expertise and trustworthiness in every acquisition.

Prices for building materials, including 4mm frosted glass, can differ significantly from one region to another, influenced by local market conditions, import tariffs, and demand levels. Areas with robust construction activities or high real estate turnover might experience greater demand, pushing prices upward. Evaluating local pricing trends versus global averages can provide buyers with a comprehensive understanding of what to expect. 4. Application Demands and Customization Usage requirements and customization options notably impact the pricing. Custom sizes, shapes, or designs typically come at a premium. A standard 4mm frosted glass sheet might be less expensive than a bespoke piece crafted for a specific architectural application. Furthermore, commercial projects could favor bulk purchases, leveraging discounts that individuals or small-scale buyers might not access. 5. Environmental Considerations and Quality Assurance With increasing attention on sustainable materials, eco-friendly production methods can affect pricing. Consumers might be willing to pay a premium for glass that is produced with reduced environmental impact. Additionally, quality certifications, warranty provisions, and after-sales services contribute to a perceived value that justifies cost. Customers are often drawn to reliable products, trusting manufacturers who demonstrate authoritative compliance with recognized industry standards. 6. Real-World Insight and Recommendations Research and first-hand experience signify that purchasing decisions should not rely solely on price. Buyers are advised to consider supplier reputability, product durability, and experiential quality. Engage with vendors to understand the support they offer, and request samples or testimonials which can speak volumes of the practical performance of 4mm frosted glass in expected conditions. In conclusion, the pricing structure of 4mm frosted glass is a multifaceted topic—intricately linked with production cost, distribution, market demand, and customization needs. By considering these dimensions, potential buyers can make informed decisions aligned with both budgetary constraints and project requirements, ensuring that they acquire the highest quality glass suitable for their needs. With the guidance of seasoned industry professionals and awareness of market nuances, the perfect balance between cost and value can be achieved, reflecting both expertise and trustworthiness in every acquisition.

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS