Aug . 14, 2025 03:00 Back to list

6mm Wired Glass: Safety, Durability & Value

The Indispensable Role of Wired Glass in Modern Architecture

In contemporary building design and construction, safety, security, and aesthetic considerations are paramount. Among the diverse range of specialized glass products, 6mm wired glass stands out as a critical material, particularly renowned for its exceptional fire-resistant properties and enhanced security features. Unlike conventional glass, wired glass incorporates a mesh of wires embedded within the glass sheet during its manufacturing process, significantly improving its structural integrity when exposed to heat or impact. This makes it an ideal choice for applications where maintaining barrier integrity under stress is crucial, such as fire doors, elevator shafts, and rooflights. Its robust composition helps prevent shattering, thus containing fire and minimizing injury from falling shards, aligning perfectly with stringent building codes and safety standards globally.

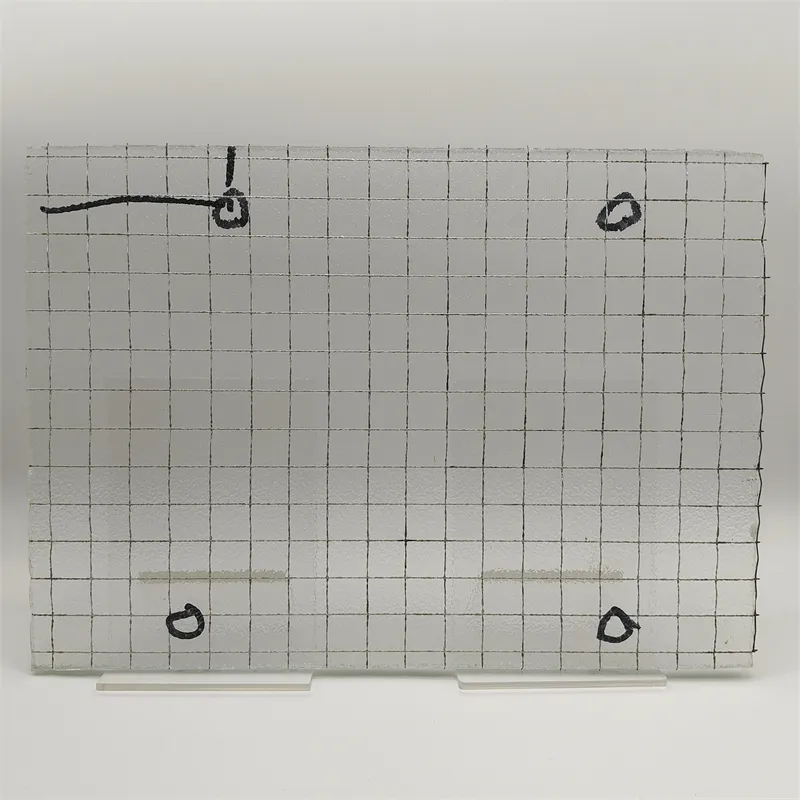

Beyond its primary safety benefits, wired glass also offers practical advantages like light diffusion, making it suitable for spaces requiring privacy without sacrificing natural illumination. The embedded wire mesh, often diamond or square patterned, also lends a unique industrial aesthetic that can complement various architectural styles. Our commitment to providing high-quality wired glass solutions ensures that clients receive products that meet specific project requirements, whether for commercial, industrial, or residential applications demanding robust fire protection and security.

The Precision Behind 6mm Wired Glass Manufacturing

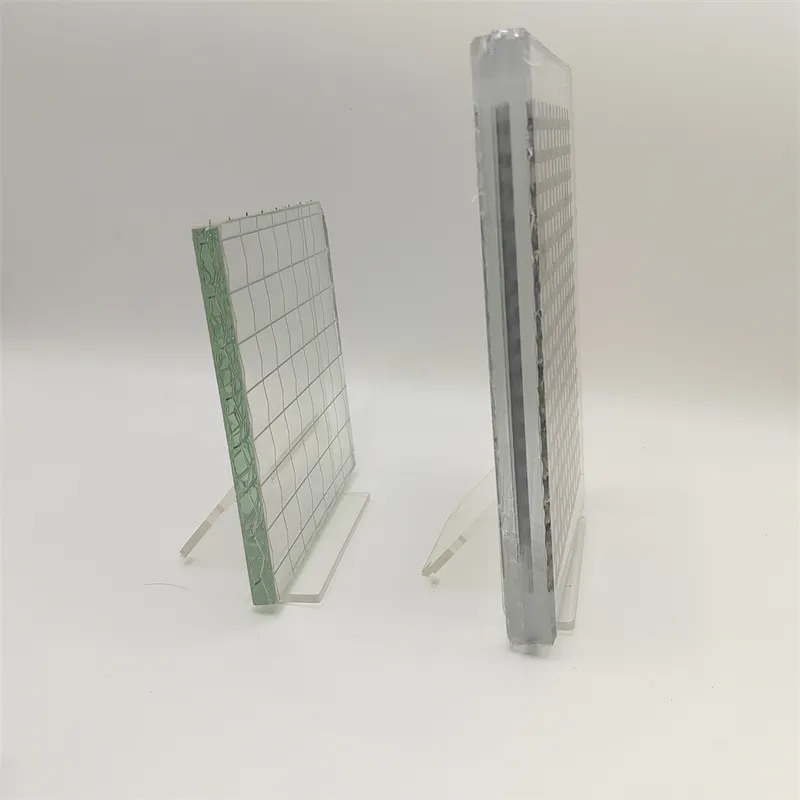

The production of 6mm wired glass is a sophisticated process that ensures its unique safety and performance characteristics. The core material is high-quality soda-lime silica glass, which provides clarity and durability. The manufacturing typically involves the rolling process, often referred to as the "cast" or "figured" glass process when incorporating wire. In this method, molten glass is poured from a furnace onto a rolling table. Simultaneously, a pre-heated steel wire mesh, typically made of high-tensile steel, is continuously fed into the molten glass stream just before it passes through a set of rollers. These rollers precisely press the wire mesh into the center of the glass sheet, ensuring it is fully encapsulated without air pockets. The thickness, specifically 6mm in this case, is meticulously controlled by the gap between these rollers.

Following the rolling process, the glass sheet undergoes meticulous annealing. This critical step involves gradually cooling the glass in a controlled oven (lehr) to relieve internal stresses, thereby enhancing its strength, reducing the risk of thermal breakage, and improving overall durability. Once annealed, the large glass sheets are cut to specified dimensions and then subjected to rigorous quality control. Key inspection standards include adherence to ISO 9001:2015 for quality management systems, ASTM C1036 for flat glass standards, and ANSI Z97.1 for safety glazing materials (where applicable for specific classifications), ensuring that each pane of wired glass meets strict performance and safety criteria. The typical service life of properly installed wired glass can exceed 30 years, demonstrating its long-term reliability in demanding environments.

Technical Specifications and Performance of 6mm Wired Glass

Understanding the precise technical parameters of 6mm wired glass is crucial for architects, engineers, and procurement professionals. This specialized glass offers a balance of optical properties, mechanical strength, and fire-resistant capabilities essential for its widespread application. Below is a comprehensive table detailing the typical specifications and performance metrics for our standard wired glass product. These parameters are rigorously tested and adhere to international standards, ensuring consistent quality and predictable performance across all batches, providing confidence in its suitability for critical installations.

| Parameter | Value / Description | Standard / Test Method |

|---|---|---|

| Thickness | 6.0 mm (Nominal) | EN 572-9, ASTM C1036 |

| Weight | Approx. 15 kg/m² | Calculated from density |

| Glass Type | Soda-lime Silica Glass | EN 572-1 |

| Wire Mesh Material | Steel Wire, Galvanized | ISO 16124, ASTM A641 |

| Wire Mesh Pattern | Square or Diamond | Visual Inspection |

| Fire Resistance Rating | E30 (Integrity for 30 min, typical for 6mm) | EN 1363-1, UL 9, NFPA 252 |

| Light Transmittance | Approx. 75-85% (depending on pattern) | ISO 9050 |

| Thermal Expansion Coefficient | 9.0 x 10^-6 /°C (20-300°C) | ISO 7991 |

| Impact Resistance | Enhanced fragmentation retention, not safety glass per se | ANSI Z97.1 (for certain uses) |

The fire resistance rating of E30 signifies that the glass maintains its integrity for at least 30 minutes when exposed to fire, preventing the passage of flames and hot gases. While 6mm wired glass is not classified as a safety glass in the same way as tempered or laminated glass for human impact protection, the embedded wire mesh effectively holds shards in place upon breakage, significantly reducing the risk of injury from falling glass. This characteristic makes it a valuable choice for environments where a degree of safety against breakage is required alongside robust fire protection.

Versatile Applications and Unmatched Advantages of Wired Glass

The unique combination of properties offered by 6mm wired glass makes it highly versatile across numerous sectors. Its primary advantage lies in its fire-retardant capabilities. When subjected to high temperatures, the wire mesh helps to hold the molten glass in place, preventing it from collapsing and maintaining the integrity of the fire barrier for a specified period. This is critical in preventing the spread of fire and smoke in buildings, allowing more time for evacuation and intervention. This characteristic is particularly vital for applications such as wired glass door panels in fire-rated assemblies, partition walls in commercial buildings, and skylights.

Beyond fire safety, wired glass provides an additional layer of security. While not bulletproof, the embedded wire mesh deters casual breakage and makes forced entry more difficult, as the glass fragments remain largely intact and attached to the wires upon impact. This provides a level of security against vandalism and accidental breakage, commonly seen in public buildings, schools, and industrial facilities. For instance, its use in a wired glass roof can enhance both fire safety and basic security against falling objects or unauthorized access. The diffusion of light by the wire mesh also offers privacy without blocking natural light, an aesthetic benefit sought after in specific architectural designs.

Applicable industries are broad, encompassing commercial and residential construction, educational institutions, healthcare facilities, and industrial complexes. For example, in large commercial spaces, wired glass is frequently used for elevator shaft enclosures and stairwell glazing to meet safety regulations. Its robustness and predictable behavior under stress make it a preferred choice where safety standards are non-negotiable, contributing to safer and more resilient building infrastructures.

Industry Trends and Market Dynamics: Understanding Wired Glass Cost and Supply

The market for wired glass is influenced by several evolving trends, including increasingly stringent building codes, a heightened focus on fire safety, and innovations in manufacturing. Globally, there's a growing demand for materials that offer passive fire protection, making 6mm wired glass a staple in many fire-rated assemblies. The global market for fire-resistant glass, which prominently features wired glass, is projected to grow significantly, driven by rapid urbanization, increased awareness of safety regulations, and a rise in commercial and residential construction projects. In terms of wired glass cost, prices are influenced by raw material costs (silica sand, soda ash, steel wire), energy prices for manufacturing, and global transportation logistics. As a specialized product, it typically commands a higher price point than standard float glass due to its complex manufacturing process and unique fire-resistant properties.

Much of the world's wired glass china production contributes substantially to the global supply chain, benefiting from advanced manufacturing capabilities and competitive pricing. This dominance helps to balance the market and ensure availability for large-scale projects worldwide. However, buyers should always prioritize suppliers with proven quality control and strict adherence to international safety standards, regardless of origin, to ensure product reliability and compliance. The shift towards higher performance and customized solutions also impacts market trends, with increased interest in specialized wire patterns and bespoke dimensions to meet unique architectural demands.

Future trends are likely to focus on further enhancements in fire ratings, potentially integrating wired glass with other technologies to achieve multi-functional properties like improved thermal insulation or sound dampening. As architectural demands evolve, the adaptability and inherent safety benefits of wired glass will continue to secure its position as a preferred material for critical applications in construction and building infrastructure.

Customization and End-to-End Solution Expertise

Recognizing that every project has unique specifications, we specialize in providing tailored solutions for 6mm wired glass. Our customization capabilities extend beyond standard sizes to include specific dimensions, various wire mesh patterns (e.g., square or diamond), and even specialized edge work or finishes to meet precise architectural and design requirements. Whether it's for a large-scale commercial complex requiring hundreds of bespoke panels or a specialized fire-rated wired glass door for a heritage building, our technical team works closely with clients from conceptualization to delivery, ensuring every detail aligns with the project vision and safety standards.

Our expertise also covers the provision of comprehensive technical support, including guidance on compliance with local and international building codes (e.g., IBC, NFPA, EN standards), installation best practices, and maintenance recommendations. We leverage decades of experience in the glass manufacturing industry to ensure that our wired glass products integrate seamlessly into complex building systems, delivering optimal performance and long-term durability. We pride ourselves on being more than just a supplier; we are a strategic partner committed to enhancing the safety, functionality, and aesthetic value of your projects with our premium glass solutions, ensuring peace of mind for our clients.

Quality Assurance, Certifications, and Industry Recognition

As a leading manufacturer and supplier of wired glass, our commitment to quality is unwavering, underpinning the trust our clients place in our products. Our manufacturing facilities adhere to the strictest international standards, including ISO 9001:2015 for Quality Management Systems, ensuring consistency and excellence across our entire production line. Each batch of 6mm wired glass undergoes rigorous internal testing for thickness uniformity, wire mesh integrity, optical clarity, and critical fire resistance performance. We conduct regular external audits and third-party certifications, such as CE marking for European markets and compliance with ASTM F500 (Standard Specification for Industrial Wire Cloth) for wire mesh quality, to validate our product claims and demonstrate our unwavering dedication to superior product quality.

Our long-standing presence in the industry, coupled with strategic partnerships with renowned architectural firms and construction companies, underscores our authority. We have been a trusted supplier for over 20 years, contributing to landmark projects globally. Our products are frequently cited in specifications for projects requiring high-level fire safety and security, from major commercial developments to critical infrastructure. This extensive experience and proven track record ensure that when you choose our wired glass, you are selecting a product backed by unparalleled expertise and reliability, consistently meeting or exceeding industry benchmarks and setting a standard for performance and safety.

Client Experience and Successful Implementations

Our wired glass has been successfully integrated into a multitude of challenging and high-profile projects, demonstrating its reliability and performance in real-world scenarios. For example, a recent project involved supplying bespoke 6mm wired glass panels for the fire-rated stairwells of a new corporate headquarters building in a major metropolitan area. The client reported exceptional ease of installation and praised the glass's adherence to stringent fire safety codes, contributing significantly to the building's overall safety rating and achieving timely project completion. Another notable application was in the renovation of an industrial complex where wired glass roof elements were chosen for their dual benefits of light transmission and enhanced security against potential break-ins, receiving positive feedback on both functionality and long-term durability in a demanding environment.

These client experiences underscore our commitment to not just deliver a product, but a complete solution that adds tangible value to projects. Our technical support team often receives accolades for their proactive approach in addressing project-specific challenges, from design considerations to logistical complexities. This hands-on collaboration ensures that our wired glass products perform as expected, providing peace of mind to project managers and end-users alike. The long-term performance data collected from these varied applications further validates the superior quality and robust design of our wired glass, making us a trusted partner for your most demanding glazing needs.

Frequently Asked Questions (FAQ) about Wired Glass

Q1: What is the primary advantage of 6mm wired glass over standard glass?

A1: The primary advantage of 6mm wired glass is its enhanced fire resistance. When exposed to fire, the embedded wire mesh holds the glass fragments in place, preventing the immediate collapse of the barrier and helping to contain the fire and smoke for a specified duration, unlike ordinary glass which can shatter and fall out quickly. It also offers a degree of security against impact and accidental breakage.

Q2: Is wired glass considered a safety glass for human impact?

A2: While the wire mesh helps retain glass fragments upon breakage, which reduces injury risk, wired glass is generally not classified as a "safety glass" under codes like ANSI Z97.1 for human impact safety without further treatment (e.g., lamination or specific tempering if available for wired variants). Its primary safety benefit is fire integrity. For applications requiring high human impact safety, tempered or laminated glass is usually specified.

Q3: What are common applications for wired glass?

A3: Common applications for wired glass include fire-rated doors and windows, elevator shaft enclosures, fire-rated partition walls, skylights, rooflights (especially wired glass roof applications), and industrial glazing where fire integrity and basic security are paramount, such as in schools, hospitals, and commercial complexes.

Q4: How does the wire mesh affect light transmission?

A4: The embedded wire mesh slightly reduces light transmission compared to clear float glass and creates a diffused light effect, which can be desirable for privacy or to reduce glare. The exact percentage of light transmission depends on the mesh pattern and density, typically ranging from 75% to 85%, offering a blend of illumination and visual obscurity.

Q5: What is the typical lead time and warranty for 6mm wired glass orders?

A5: Delivery cycles for 6mm wired glass typically range from 2 to 4 weeks, depending on order volume, customization requirements, and current production schedules. We offer a standard 5-year warranty on our wired glass against manufacturing defects, underscoring our confidence in product quality. Our dedicated customer support team is available to assist with any post-purchase inquiries or technical assistance, ensuring comprehensive client support.

Procurement, Logistics, and Customer Support

Navigating the procurement of specialized materials like 6mm wired glass requires clear communication and reliable logistics. We streamline the entire process, from initial inquiry to final delivery, ensuring a seamless experience for our B2B clients. Our robust supply chain management, particularly with significant manufacturing hubs like wired glass china, enables us to handle both large-volume orders and specialized custom requests efficiently. Typical delivery cycles range from 2 to 4 weeks for standard orders, with expedited options available for urgent projects, all clearly communicated and confirmed during the quotation phase, allowing for precise project planning.

We stand behind the quality of our products with a comprehensive 5-year warranty against manufacturing defects, reflecting our commitment to excellence and durability. Our dedicated customer support team provides extensive after-sales service, including technical guidance for installation, advice on maintenance, and prompt resolution of any issues that may arise. This commitment to end-to-end support ensures that our wired glass not only meets but consistently exceeds performance expectations throughout its long service life, reinforcing our promise of reliability and client satisfaction for every project.

Conclusion

In an era where building safety and functional design are non-negotiable, 6mm wired glass remains an indispensable component for architects, developers, and safety professionals. Its proven fire resistance, added security benefits, and aesthetic versatility make it a superior choice for critical applications within diverse building environments. As a professional B2B partner, we are dedicated to supplying premium wired glass solutions that not only comply with the most stringent international standards but also contribute significantly to the safety and longevity of your projects. Our extensive expertise, unwavering commitment to quality, and client-centric approach ensure that every project benefits from reliable, high-performance glass products tailored to exact specifications, making us the ideal choice for your glazing needs.

References

- National Fire Protection Association (NFPA) Standards for Fire Doors and Other Opening Protectives.

- ASTM International Standards for Glass and Glazing Products, particularly ASTM C1036 Standard Specification for Flat Glass.

- International Building Code (IBC) sections pertaining to fire-resistance-rated construction and opening protectives.

- European Committee for Standardization (CEN) EN 1363-1 Fire Resistance Tests – General Requirements.

- ISO (International Organization for Standardization) 9001:2015 Quality management systems – Requirements.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS