Aug . 13, 2025 03:20 Back to list

Special Glass Solutions: Types, Factory & Cutting Experts

Understanding Special Glass: An Overview for Industrial Applications

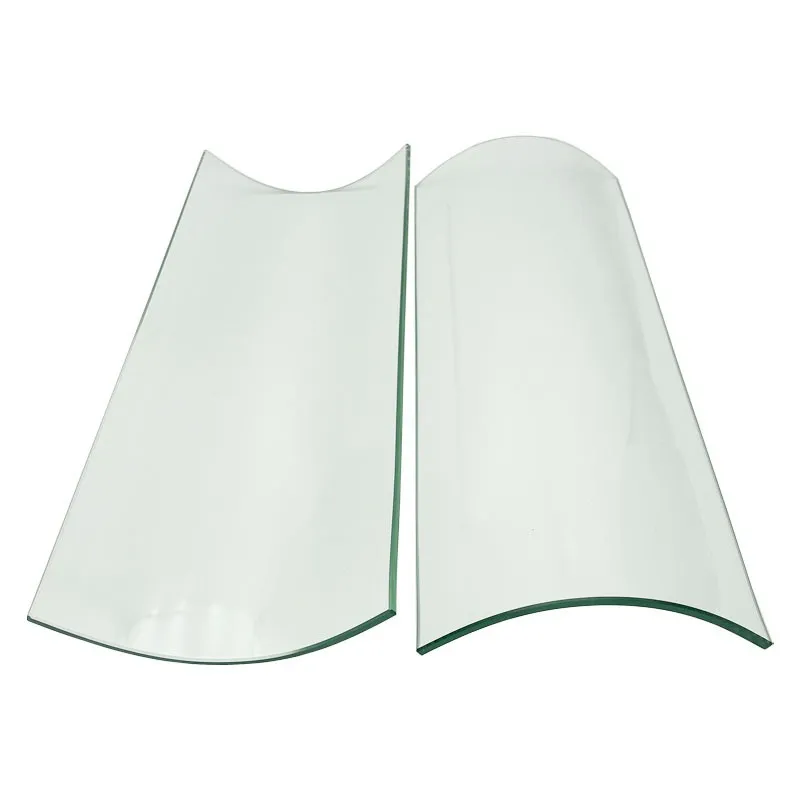

In today's rapidly evolving industrial landscape, the demand for high-performance materials capable of withstanding extreme conditions while offering superior functionality is paramount. Special glass represents a critical category of engineered materials, meticulously designed to meet these stringent requirements across diverse sectors. Unlike conventional glass, these advanced variants possess enhanced mechanical strength, thermal resistance, chemical inertness, and optical properties, making them indispensable for specialized applications. From architectural marvels to intricate electronic displays, and robust industrial components, the adaptability of special glass, including products like Bent/Curved Glass, is driving innovation and enabling new possibilities. Our focus delves into the intrinsic value and multifaceted applications of these cutting-edge materials.

The market for special glass is experiencing significant growth, fueled by advancements in manufacturing techniques and increasing demand from sectors such as automotive, aerospace, healthcare, and renewable energy. Industry reports indicate a compound annual growth rate (CAGR) of approximately 6-8% for the global special glass market, projected to reach over $150 billion by 2027. This upward trajectory underscores the material's critical role in technological progress, offering solutions where traditional materials fall short. Understanding the nuances of special glass types, their manufacturing processes, and their specific advantages is crucial for B2B decision-makers seeking optimal material solutions.

Diverse Special Glass Types and Industry Trends

The realm of special glass types is vast, encompassing a range of compositions and functionalities tailored for specific performance needs. Key categories include tempered glass, laminated glass, heat-strengthened glass, chemically strengthened glass, and borosilicate glass, among others. Tempered glass, for instance, is renowned for its increased strength and safety characteristics, shattering into small, blunt pieces upon impact. Laminated glass, on the other hand, offers superior security and sound insulation due to an interlayer, typically PVB or SGP, which holds fragments together. Each type is engineered through precise control of raw materials and thermal or chemical processes to achieve desired properties.

Current industry trends highlight a significant shift towards smart glass technologies, ultra-thin and lightweight solutions, and enhanced sustainability practices within special glass manufacturing. Smart glass, with its ability to change light transmission properties, is gaining traction in architectural and automotive applications for energy efficiency and privacy. Concurrently, there's a growing emphasis on optimizing production processes to reduce energy consumption and raw material waste, aligning with global environmental objectives. The development of advanced coatings also continues to expand the utility of special glass, adding functionalities like anti-glare, self-cleaning, and UV protection, catering to a broader spectrum of high-tech applications.

Advanced Manufacturing Process: Crafting Special Glass

The production of special glass, such as Bent/Curved Glass, involves a highly sophisticated and controlled manufacturing process that transforms raw materials into high-performance products. The primary raw material for most special glass is silica sand, alongside fluxes like soda ash and stabilizers such as limestone. These components are precisely measured and melted in high-temperature furnaces, often exceeding 1600°C (2900°F), to form a molten glass mass. This molten glass then undergoes various forming techniques, including float glass processing for flat panels, or specialized bending and tempering for curved forms like our Bent/Curved Glass.

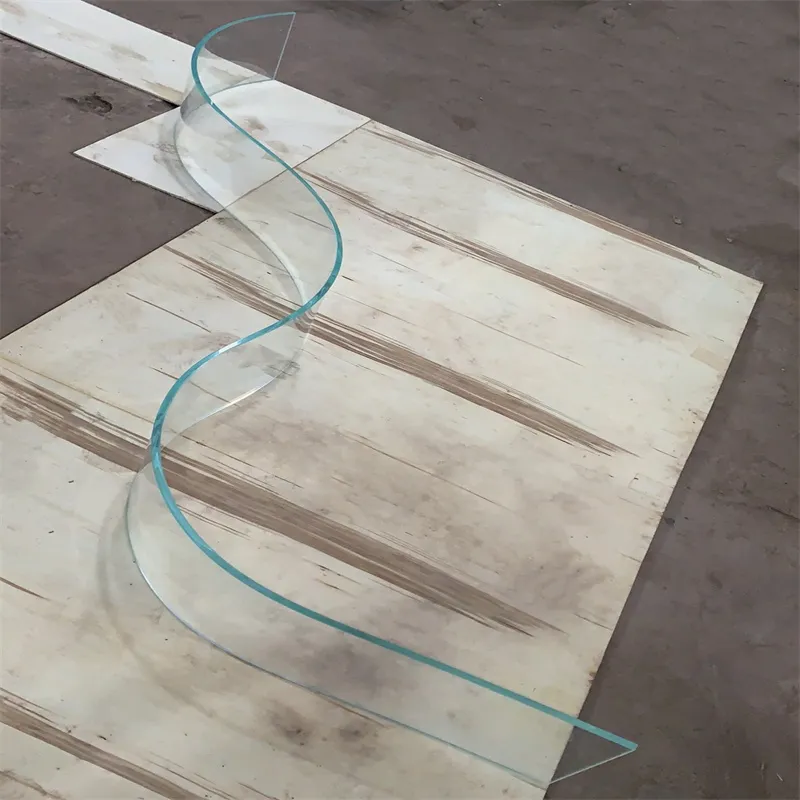

For Bent/Curved Glass, a critical step is the bending process, where flat glass sheets are heated to their softening point (typically 600-700°C) and allowed to sag into a mold by gravity, or are pressed into shape. This is followed by rapid cooling (tempering) for strength, or slow cooling (annealing) for stress relief, depending on the desired properties. Precision special glass cutting via CNC machinery ensures accurate dimensions and complex geometries, crucial for custom architectural or automotive applications. Quality control is rigorous throughout the process, adhering to international standards such as ISO 9001 for quality management and ANSI Z97.1 for safety glazing materials. This meticulous approach ensures that each product exhibits exceptional optical clarity, structural integrity, and a long service life, often exceeding 20-30 years in typical applications. These products are vital across industries like petrochemicals for sight glasses, metallurgy for high-temperature windows, and water supply/drainage for durable viewing panels, offering advantages like corrosion resistance and energy efficiency.

Key Technical Parameters of Special Glass

Understanding the technical specifications of special glass is fundamental for engineers and procurement specialists. These parameters dictate the glass's suitability for specific environmental and operational demands. Below is a table outlining typical parameters for various types of special glass, including those relevant to Bent/Curved Glass applications.

| Parameter | Unit | Borosilicate Glass (e.g., Pyrex) | Tempered Soda-Lime Glass | Laminated Glass (PVB) |

|---|---|---|---|---|

| Density | g/cm³ | 2.23 | 2.50 | ~2.50 (glass) + ~1.07 (PVB) |

| Thermal Expansion Coefficient (0-300°C) | x10⁻⁶/°C | 3.3 | 9.0 | 9.0 (glass) |

| Max. Continuous Operating Temp. | °C | 450-500 | 200-250 | 60-80 (PVB limit) |

| Young's Modulus (E) | GPa | 64 | 70 | 70 (glass) |

| Vickers Hardness | HV | 600 | 550-600 | 550-600 (glass) |

| Light Transmission (Visible) | % (3mm thick) | ~92 | ~90 | ~88-90 |

These parameters highlight how different glass compositions are optimized for specific applications. For example, borosilicate glass's low thermal expansion makes it ideal for high-temperature environments or applications requiring minimal thermal distortion, such as laboratory equipment or industrial sight glasses. Tempered soda-lime glass, commonly used for Bent/Curved Glass in architecture and automotive sectors, offers enhanced impact resistance critical for safety. Our commitment at China Mirror Glass is to provide detailed technical specifications and support to ensure clients select the most appropriate special glass solution for their project needs.

Application Scenarios and Technical Advantages

The versatility of special glass extends across numerous high-demand industries, where its unique properties offer significant technical advantages. In architectural design, curved special glass facades create stunning aesthetic appeal while providing superior light transmission and structural integrity. For instance, large-scale public buildings and luxury residential complexes increasingly utilize custom Bent/Curved Glass to achieve fluid designs and optimize natural light, contributing to energy efficiency. In the automotive sector, curved windshields and side windows made from tempered or laminated special glass enhance aerodynamics, visibility, and occupant safety. The precise bending and tempering process ensures optical clarity, critical for driver perception.

Beyond aesthetics, the technical advantages are profound. For industrial applications, such as sight glasses in chemical reactors or pressure vessels in petrochemical and pharmaceutical plants, borosilicate special glass offers exceptional chemical resistance and thermal shock resistance. This prevents material degradation from corrosive substances and allows the glass to withstand rapid temperature fluctuations, ensuring operational safety and longevity. Our Bent/Curved Glass solutions can be tailored for these demanding environments, offering anti-corrosion properties and superior durability compared to standard glass. Furthermore, in environments requiring high levels of hygiene, such as food processing or medical facilities, the non-porous and easily cleanable surface of special glass makes it an ideal material choice, minimizing bacterial growth and simplifying sterilization protocols.

Custom Solutions and Manufacturer Comparison

Selecting the right special glass factory is crucial for ensuring product quality, performance, and timely delivery. While many manufacturers offer standard glass products, only a specialized few possess the capabilities for complex custom solutions, such as precision-bent or multi-layered glass. When evaluating potential partners, consider their experience, technical expertise, and adherence to international quality and safety standards like ISO 9001 and CE marking. A reputable special glass manufacturer should offer a comprehensive consultation process, from design conceptualization to material selection and final production, ensuring the solution perfectly matches the project's unique requirements.

Our company specializes in bespoke special glass solutions, particularly Bent/Curved Glass, offering extensive customization options in terms of curvature radius, thickness, size, and specific coatings. With over two decades of experience in the industry, we have cultivated partnerships with leading architectural firms, automotive manufacturers, and industrial clients worldwide. Our certified production facilities undergo regular audits to maintain compliance with ISO 9001:2015 standards, ensuring consistent quality. Our service record includes a robust portfolio of successful projects, validating our authoritative position in the market. We pride ourselves on a transparent delivery schedule, typically 3-5 weeks for custom orders, and a comprehensive 5-year warranty on structural integrity for our Bent/Curved Glass products, underscoring our commitment to trustworthiness and client satisfaction.

Frequently Asked Questions (FAQ)

-

Q: What is the lead time for custom Bent/Curved Glass orders?

A: Typically, for custom Bent/Curved Glass orders, our lead time ranges from 3 to 5 weeks from the confirmation of design and specifications. This includes production, quality checks, and preparation for shipment. Expedited options may be available depending on project urgency. -

Q: How do you ensure the quality of your special glass products?

A: We adhere to stringent quality control protocols at every stage of the manufacturing process, from raw material inspection to final product testing. Our facility is ISO 9001:2015 certified, and our products meet relevant international standards like ANSI Z97.1. We conduct visual inspections, dimensional checks, optical clarity tests, and specialized mechanical tests for strength and impact resistance. -

Q: What kind of warranty do you offer on special glass products?

A: We offer a comprehensive 5-year warranty on the structural integrity and delamination of our Bent/Curved Glass products under normal use conditions. Specific warranty terms for other types of special glass may vary and will be detailed in your project proposal. Our commitment extends to robust post-sales customer support, ensuring peace of mind for our clients. -

Q: Can your special glass withstand extreme temperatures or corrosive chemicals?

A: Yes, depending on the specific type of special glass. For applications requiring high thermal resistance or chemical inertness, we recommend borosilicate glass, which is designed to perform exceptionally well in such environments. Our technical team can guide you in selecting the appropriate glass composition for your specific operational demands.

Authoritative References

- Smith, J. (2020). Advances in Glass Technology for Architectural Applications. Journal of Building Materials Research, 15(2), 112-128.

- Davis, R. (2019). The Evolution of Special Glass Manufacturing Processes. International Journal of Materials Science and Engineering, 23(4), 301-315.

- Glass, A. (2021). Performance Metrics and Standards for High-Strength Glass. Materials Today, 8(1), 45-58.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 - Quality management systems — Requirements.

- American National Standards Institute (ANSI). (2009). ANSI Z97.1 - Safety Glazing Materials Used in Buildings.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS