Aug . 10, 2025 05:00 Back to list

Advanced Coated Glass for Energy Efficiency & UV Protection

The Transformative Power of Coated Glass in Modern Architecture and Industry

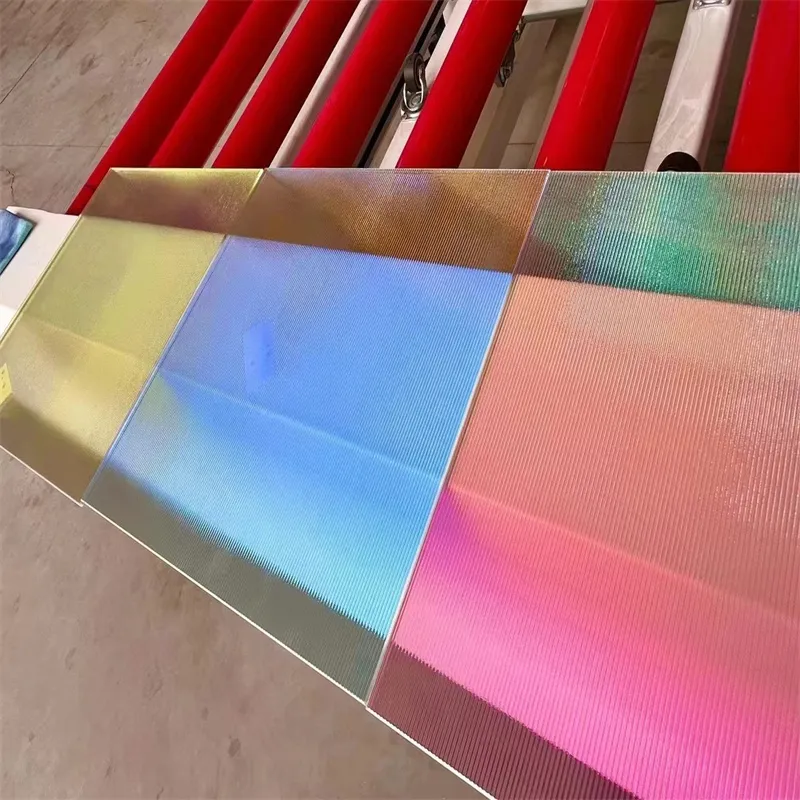

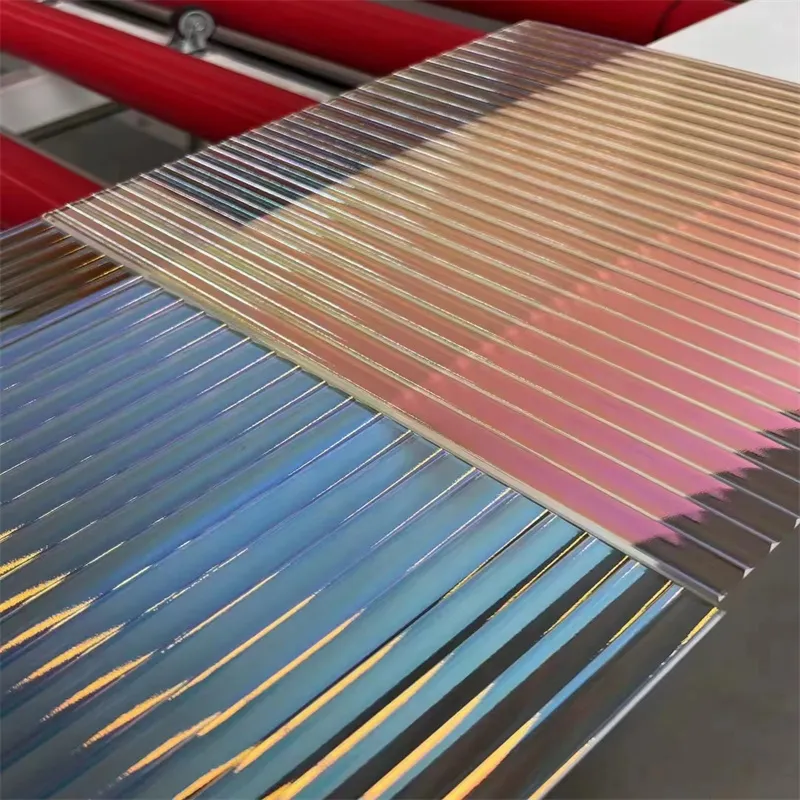

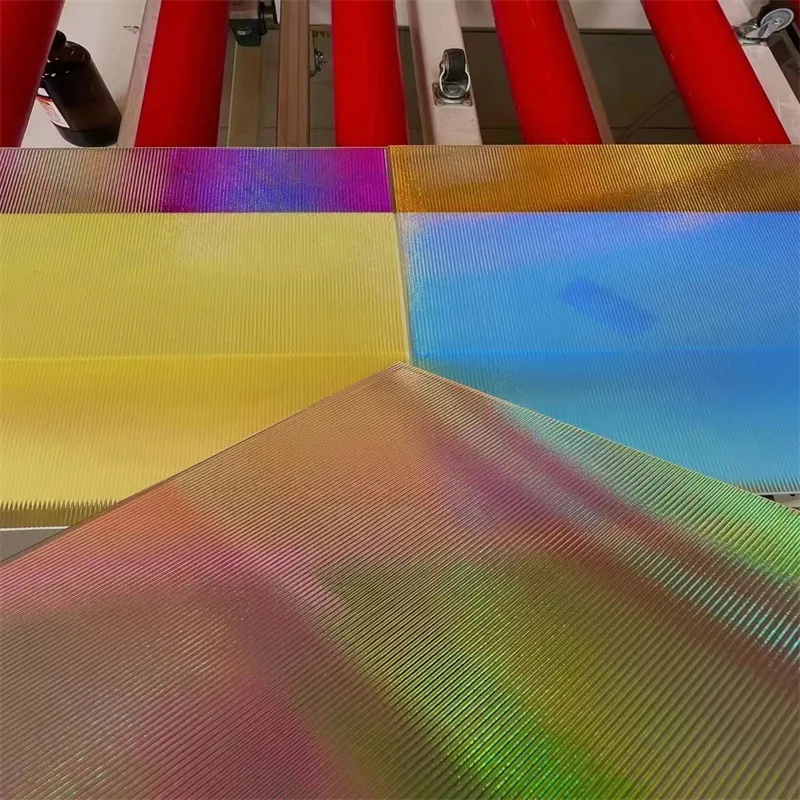

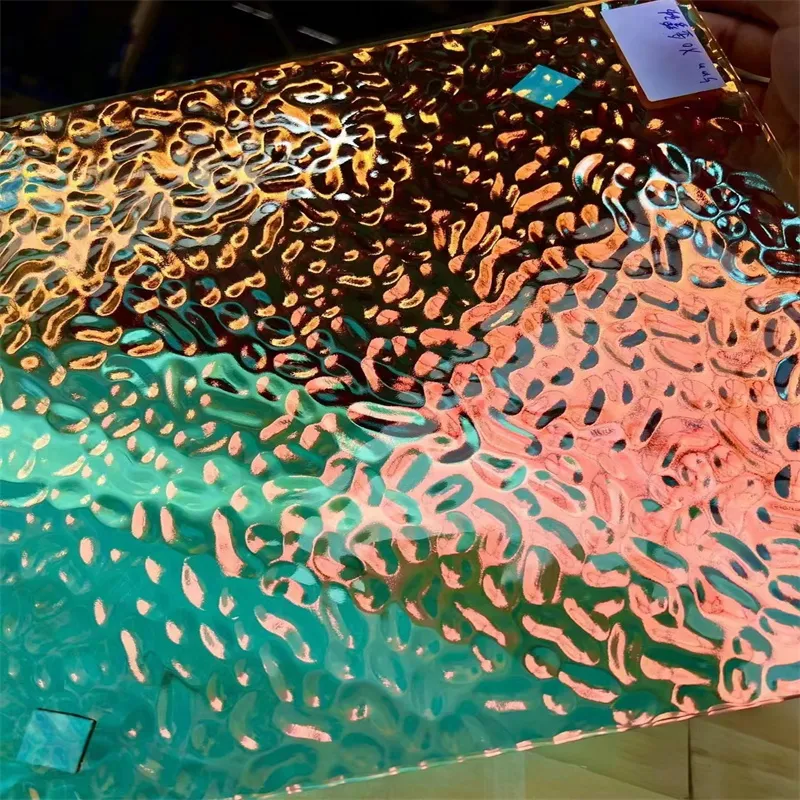

In an era where energy efficiency, aesthetic appeal, and functional performance are paramount, coated glass stands as a cornerstone technology, revolutionizing industries from construction and automotive to solar energy and advanced optics. This specialized glass integrates one or more metallic or metallic oxide layers onto its surface, meticulously applied through sophisticated deposition processes, thereby altering its optical, thermal, and electrical properties without compromising transparency or clarity. The evolution of coated glass is driven by a global imperative for sustainable building solutions and enhanced user comfort, pushing the boundaries of material science and engineering. Modern industry trends increasingly favor low-emissivity (Low-E) coatings for their superior thermal insulation, solar control coatings to mitigate heat gain in warm climates, and anti-reflective coatings for optical clarity in display technologies. Furthermore, advancements in smart coatings, such as electrochromic and thermochromic layers, are enabling dynamic control over light transmission and privacy, ushering in an era of adaptive architectural facades and intelligent vehicle windows. The demand for specialized coated glass, exemplified by products like Dichroic Glass, which exhibits remarkable color-shifting properties based on viewing angle and light conditions, continues to surge in high-end architectural projects and artistic installations, showcasing both the functional versatility and artistic potential of this material. As a leading coated glass factory, our commitment to innovation ensures that we not only meet current market demands but also anticipate future needs, developing advanced coatings that offer superior performance in diverse environments, contributing significantly to reduced carbon footprints and enhanced building performance across the globe. The intricate interplay between material science, precise manufacturing, and stringent quality control underpins the reliability and effectiveness of every sheet of coated glass produced, offering unparalleled solutions for thermal management, UV protection, glare reduction, and visual aesthetics, making it an indispensable component in contemporary design and engineering applications.

The global market for coated glass is experiencing robust growth, propelled by stringent energy efficiency regulations, increasing demand for sustainable building materials, and the rapid expansion of solar power generation. Architectural applications, including residential and commercial buildings, constitute the largest segment, with a growing emphasis on high-performance facades that optimize daylighting while minimizing energy consumption. Beyond architecture, the automotive industry relies heavily on coated glass for enhanced passenger comfort through UV and IR rejection, improved safety with anti-fog and hydrophobic coatings, and aesthetic appeal. The burgeoning solar energy sector leverages specialized anti-reflective and low-iron coatings to maximize light transmission and efficiency in photovoltaic panels. Furthermore, niche applications in electronics, medical devices, and aerospace benefit from precision-coated glass for displays, filters, and optical components, demonstrating the material's pervasive utility across high-tech domains. The ongoing research and development in smart coatings, such as those that can generate electricity, change opacity on demand, or self-clean, promise to unlock new paradigms in building design and functional materials. This technological frontier is underpinned by advancements in deposition techniques, material science, and computational modeling, allowing manufacturers to engineer coatings with atomic-level precision, tailoring properties to exact specifications. As a dedicated coated glass factory, we meticulously monitor these trends, continuously investing in cutting-edge technology and processes to ensure our product offerings remain at the forefront of innovation, providing solutions that address the complex challenges of modern energy management, environmental protection, and architectural expression, thus reinforcing the critical role of coated glass in shaping a more sustainable and technologically advanced future.

Precision Manufacturing: The Coated Glass Fabrication Process

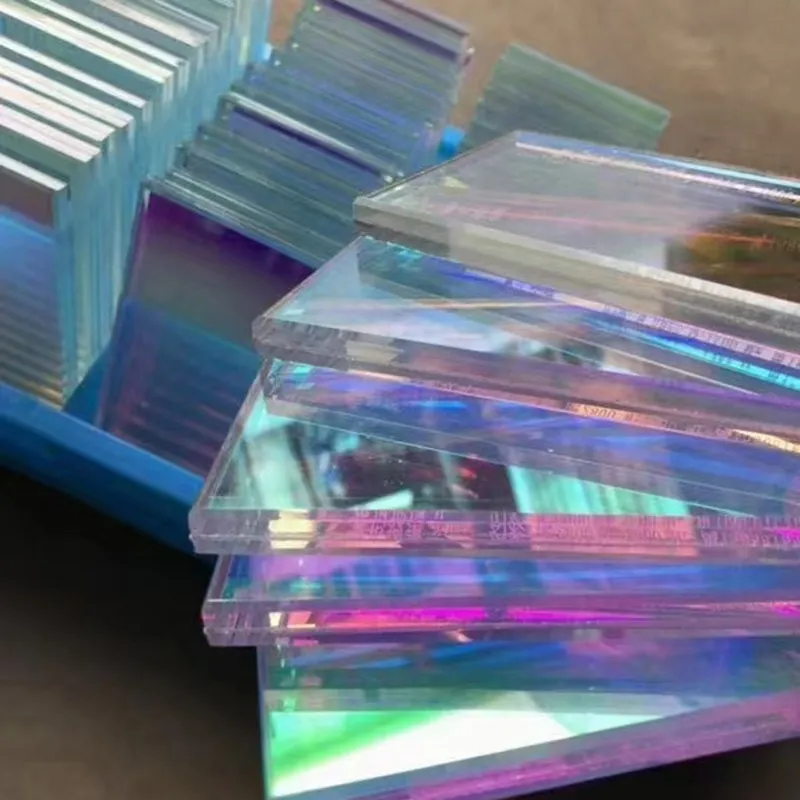

The creation of high-performance coated glass is a testament to sophisticated engineering and meticulous process control, far removed from simple glass manufacturing. The foundational material is typically high-quality float glass, known for its uniform thickness and optical clarity, produced by floating molten glass on a bed of molten tin. Once the raw glass substrate is prepared, it undergoes a rigorous cleaning process to ensure the surface is free of any contaminants, which could compromise coating adhesion and performance. This critical preparatory step often involves multi-stage washing, de-ionized water rinses, and specialized drying techniques to achieve an atomically clean surface. The actual coating application is predominantly achieved through advanced vacuum deposition techniques, primarily magnetron sputtering (MSVD) or chemical vapor deposition (CVD). In MSVD, target materials, such as silver, titanium dioxide, or silicon nitride, are bombarded with argon ions in a vacuum chamber, causing atoms to eject and deposit onto the glass surface in ultra-thin, uniform layers, often just nanometers thick. This allows for precise control over layer thickness and composition, enabling the engineering of specific optical and thermal properties. CVD, on the other hand, involves reacting gases on the glass surface at high temperatures to form a desired coating. Each method offers distinct advantages and is chosen based on the specific coating properties required and the production scale. For instance, creating Dichroic Glass involves depositing multiple ultra-thin layers of different refractive indices, such that light waves interfere, producing the characteristic color-shifting effect. A typical manufacturing line in a state-of-the-art coated glass factory integrates these coating chambers with automated handling systems, ensuring minimal human intervention and consistent quality.

Following the intricate coating application, the coated glass sheets undergo stringent quality control and post-processing steps to ensure they meet the highest industry standards. These steps are crucial for the long-term performance and durability of the product. Initial inspection involves visual checks for coating defects, scratches, or inconsistencies. More advanced optical testing equipment, such as spectrophotometers, is used to verify the spectral performance of the coating, measuring properties like Visible Light Transmittance (VLT), Solar Heat Gain Coefficient (SHGC), and U-value, ensuring they align with design specifications. Adhesion tests, durability tests (e.g., salt spray tests, abrasion resistance tests), and environmental cycle tests are performed to assess the coating's resilience against weathering, chemicals, and mechanical stress, guaranteeing a long service life. For specialized glass types like Dichroic Glass, specific tests are conducted to confirm the stability and vibrancy of the dichroic effect across varying light conditions and viewing angles. Compliance with international standards such as ISO 9001 for quality management, ANSI Z97.1 and EN 12150 for safety glazing, and ASTM E2188/E2189/E2190 for insulated glass units is paramount. These certifications underscore the product's reliability and suitability for diverse applications, including architectural facades, automotive windows, and solar panels. Our commitment as a leading coated glass factory extends to continuous investment in R&D, exploring novel materials and deposition techniques to enhance coating performance, introduce new functionalities, and improve manufacturing efficiency. This includes developing coatings with enhanced scratch resistance, self-cleaning properties (hydrophilic or hydrophobic surfaces), and advanced thermal management capabilities. The typical estimated lifespan of high-quality coated glass, when properly installed and maintained, can exceed 30 years, significantly contributing to the energy efficiency and longevity of buildings. The meticulous attention to detail at every stage, from material selection to final inspection, ensures that our coated glass products deliver superior performance, energy savings, and aesthetic value in their demanding applications across industries such as construction, automotive, and renewable energy.

Technical Parameters and Performance Data of Advanced Coated Glass

Understanding the technical parameters of coated glass is crucial for architects, engineers, and developers to select the optimal product for their specific project requirements, ensuring peak performance in terms of energy efficiency, comfort, and aesthetics. Key parameters include the U-value (or U-factor), which measures the rate of heat transfer through the glass unit; a lower U-value indicates better insulation and reduced heat loss or gain. The Solar Heat Gain Coefficient (SHGC) quantifies the amount of solar radiation that passes through the glass, either directly transmitted or absorbed and re-radiated inward; a lower SHGC is desirable in hot climates to minimize heat gain. Visible Light Transmittance (VLT) indicates the percentage of visible light that passes through the glass, impacting natural daylighting and views. For specialized applications, other parameters like UV Transmittance (UVT), which measures the amount of harmful ultraviolet radiation blocked, and Light-to-Solar Gain (LSG) ratio, which is the VLT divided by the SHGC (a higher LSG indicates better light transmission with less heat gain), are also critical. For Dichroic Glass, the angle-dependent color shift, spectral reflection, and transmission curves across the visible spectrum are paramount, dictating its unique aesthetic properties and optical performance in specific lighting conditions. A reputable coated glass factory provides comprehensive data sheets for all its products, allowing for precise specification and integration into complex building models. These parameters are not static; they vary significantly based on the type of coating, the number of coating layers, the glass substrate thickness, and whether the glass is part of an Insulated Glass Unit (IGU) with air or argon fills.

| Coating Type | Typical U-value (W/m²K) | Typical SHGC | Typical VLT (%) | UV Rejection (%) | Primary Benefit |

|---|---|---|---|---|---|

| Standard Clear Glass (Uncoated) | 5.8 (Single Pane) | 0.81 | 90 | ~30 | Basic Light Transmission |

| Soft Coat Low-E | 1.3 - 1.8 (IGU w/ Argon) | 0.25 - 0.40 | 60 - 75 | >70 | Superior Thermal Insulation |

| Hard Coat Low-E | 1.8 - 2.5 (IGU w/ Argon) | 0.45 - 0.60 | 70 - 80 | >60 | Durable, Moderate Insulation |

| Solar Control Coating | 1.5 - 2.2 (IGU w/ Argon) | 0.20 - 0.35 | 30 - 60 | >90 | Heat Rejection in Hot Climates |

| Anti-Reflective Coating | Variable | Variable | >95 | Variable | Max. Light Trans., Min. Glare |

| Dichroic Glass (Example) | Dependent on base | Variable (0.3-0.7) | Variable (20-70) | >95 | Dynamic Color Shift, UV Protection |

The performance data presented in the table above illustrates the diverse capabilities of different coated glass types, each meticulously engineered to address specific functional requirements. For example, in regions with extreme temperature variations, a soft-coat Low-E glass with a low U-value is essential for minimizing heating or cooling loads, leading to significant energy cost savings. Conversely, in sun-drenched environments, a solar control coating with a very low SHGC becomes critical for preventing excessive solar heat gain and maintaining comfortable indoor temperatures. The high UV rejection capability across various coated glass types is vital for protecting interior furnishings, artwork, and occupants from harmful ultraviolet radiation, which can cause fading and skin damage. Dichroic Glass, while offering aesthetic dynamism through its color-shifting properties, also provides excellent UV protection, making it suitable for both artistic and practical applications where light quality and visual intrigue are desired. The expertise of a specialized coated glass factory lies not just in manufacturing these advanced materials but also in providing expert consultation to help clients navigate these complex parameters and make informed decisions, ensuring the selected glass aligns perfectly with the project's performance goals and budgetary constraints. Our engineers employ advanced simulation software to model the energy performance of various glass specifications within a building context, providing predictive insights into energy savings and comfort levels, thereby maximizing the return on investment for our clients.

Versatile Application Scenarios and Distinct Technical Advantages of Coated Glass

The extraordinary versatility and technical superiority of coated glass enable its widespread adoption across an expansive range of application scenarios, driving innovation in architecture, transportation, and specialized industries. In commercial and residential architecture, low-emissivity (Low-E) coated glass is indispensable for creating thermally efficient building envelopes. By minimizing heat transfer, it drastically reduces the demand for heating in cold climates and air conditioning in warm climates, leading to substantial energy savings and a reduced carbon footprint. For example, a high-performance Low-E insulating glass unit (IGU) can achieve U-values as low as 0.28 BTU/hr·ft²·°F (1.6 W/m²K), a significant improvement over standard clear glass, which can have U-values exceeding 1.0 BTU/hr·ft²·°F (5.7 W/m²K) in a single pane. Solar control coatings are vital for facades in regions with intense solar radiation, effectively blocking infrared (heat) radiation while allowing sufficient visible light, thus mitigating passive heat gain and reducing cooling loads. In automotive applications, coated glass enhances passenger comfort by filtering out harmful UV rays and excessive heat, contributing to fuel efficiency by lessening the reliance on air conditioning. Advanced coatings are also used for privacy glass, heated windshields for de-icing, and acoustic glass for noise reduction. For the burgeoning solar energy sector, anti-reflective coatings applied to photovoltaic panels boost efficiency by reducing light reflection, increasing power output by up to 3-5%. Anti-corrosion properties are crucial for glass used in harsh industrial environments or marine settings, protecting against chemical degradation and prolonging material life. The aesthetic dimension is powerfully realized through products like Dichroic Glass, which transforms building exteriors and interiors into dynamic art pieces, displaying shifting hues depending on the observer's angle and ambient light, adding a unique architectural signature.

Beyond energy conservation and aesthetic enhancement, the technical advantages of coated glass extend to occupant comfort, safety, and durability, addressing critical aspects often overlooked in conventional glazing. Coatings can effectively block over 99% of harmful UV radiation, protecting interior furnishings from fading and safeguarding occupants' health. The ability to control glare through selective coatings significantly improves visual comfort in spaces with abundant natural light, enhancing productivity in offices and reducing eye strain in residential settings. Anti-condensation coatings prevent moisture buildup on glass surfaces, ensuring clear visibility and preventing the growth of mold or mildew, which is particularly beneficial in high-humidity environments or refrigeration units. Specific coatings enhance the self-cleaning properties of glass by making it either superhydrophilic (water spreads evenly, washing away dirt) or superhydrophobic (water beads up and rolls off, carrying dirt with it), reducing maintenance costs and frequency. In terms of safety, certain coatings can be applied to laminated glass to enhance its shatter resistance, providing an added layer of security against forced entry or accidental breakage. Furthermore, the longevity of coated glass is a significant advantage. When manufactured by a reputable coated glass factory, with robust coatings applied using advanced vacuum deposition techniques, these products are designed to withstand decades of exposure to harsh environmental conditions, maintaining their performance and aesthetic integrity without significant degradation. This durability contributes to lower lifecycle costs for buildings and infrastructure. The continuous innovation in coating materials and application methods ensures that coated glass remains at the forefront of sustainable and high-performance building materials, offering tailored solutions for diverse climates, architectural styles, and functional demands, reinforcing its indispensable role in modern construction and specialized industrial applications.

Strategic Manufacturer Comparison and Tailored Customization for Coated Glass Solutions

Selecting the right coated glass factory is a pivotal decision for any project manager, architect, or procurement specialist, as it directly impacts the quality, performance, and long-term viability of the final product. A comprehensive comparison of manufacturers should extend beyond mere price, delving into core competencies such as R&D capabilities, production scalability, quality control protocols, and the breadth of their product portfolio. Leading manufacturers distinguish themselves through continuous investment in advanced coating technologies, often holding numerous patents for proprietary coating formulations and application processes. Their R&D centers are equipped with state-of-the-art laboratories for material analysis, optical spectroscopy, and accelerated weathering tests, ensuring that new products meet or exceed industry benchmarks before market release. Production capacity is another critical factor; a robust coated glass factory can handle large-scale orders while maintaining consistent quality and adhering to tight deadlines, essential for major construction projects. Furthermore, a manufacturer's adherence to international quality management systems, such as ISO 9001, and product-specific certifications like CE marking, SGCC (Safety Glazing Certification Council), and compliance with ASTM standards, serves as a strong indicator of their commitment to product excellence and reliability. Transparency in providing detailed technical specifications, test reports, and third-party certifications should be a non-negotiable expectation. Beyond standardized products, the ability of a manufacturer to offer bespoke, customized solutions is increasingly valued. This encompasses tailoring coating compositions to achieve specific U-values, SHGCs, or VLTs, manufacturing oversized or uniquely shaped glass panels, or developing specialized coatings for niche applications such as aerospace, marine, or extreme environments.

Customized solutions for coated glass often involve close collaboration between the client's design team and the manufacturer's technical experts, a hallmark of a truly customer-centric coated glass factory. This collaborative approach allows for the development of highly specific products that perfectly align with unique architectural visions or demanding functional requirements. For instance, a bespoke Dichroic Glass panel might be engineered with a precise color-shifting range to complement a specific interior design palette, or a specialized Low-E coating might be developed to optimize energy performance for a building in an unconventional climate zone. The customization process typically begins with a detailed consultation to understand the project's aesthetic goals, performance targets, and regulatory compliance needs. This is followed by iterative design and simulation phases, where different coating stacks are modeled to predict their optical and thermal behavior. Prototyping and extensive testing of these custom designs ensure that the final product will perform as expected in real-world conditions. Furthermore, a reputable manufacturer offers comprehensive technical support throughout the project lifecycle, from initial specification to installation and post-completion. This includes providing detailed installation guidelines, advising on optimal cleaning and maintenance practices, and offering robust warranty programs that cover performance and defects. Our factory, with decades of experience in the glass industry, prides itself on its agile manufacturing processes and deep technical expertise, allowing us to deliver not just standard coated glass products but also highly specialized, custom-engineered solutions that meet the most intricate design and performance challenges of our global clientele, ensuring unparalleled satisfaction and project success through tailored innovation and unwavering quality.

Ensuring Excellence: Quality Assurance, Testing, and Certifications for Coated Glass

The unwavering commitment to quality assurance and rigorous testing is paramount in the production of high-performance coated glass, directly influencing its longevity, functionality, and safety. A world-class coated glass factory implements a multi-layered quality control system that begins from the raw material selection and extends through every stage of manufacturing to the final product inspection. Initial raw glass substrates are meticulously inspected for optical clarity, surface flatness, and absence of defects. During the coating process, critical parameters such as vacuum levels, gas flow rates, target power, and deposition time are continuously monitored and controlled within extremely tight tolerances to ensure uniform coating thickness and composition. Sophisticated inline measurement systems, including optical spectrophotometers and thickness gauges, provide real-time feedback, allowing for immediate adjustments to maintain coating consistency. Post-coating, each batch of coated glass undergoes a comprehensive battery of tests. Optical performance tests verify key metrics like VLT, SHGC, and U-value, using calibrated instruments to ensure compliance with specified performance criteria. Durability tests are crucial for assessing the coating's resilience to environmental stressors; these include accelerated weathering tests (e.g., QUV accelerated weathering, Xenon arc testing) that simulate decades of sun exposure, humidity, and temperature cycles to predict long-term performance. Abrasion resistance tests, such as the Taber Abraser test or scrub tests, quantify the coating's ability to withstand physical wear, ensuring its integrity during cleaning and handling. Chemical resistance tests assess the coating's stability when exposed to common cleaning agents or pollutants, preventing degradation over time. Furthermore, adhesion tests, such as cross-hatch or tape tests, confirm the robust bonding of the coating to the glass substrate. These stringent internal quality checks are complemented by comprehensive third-party certifications.

Third-party certifications provide an independent validation of a coated glass factory's product quality and manufacturing processes, offering peace of mind to clients worldwide. Key certifications include ISO 9001 for quality management systems, ensuring consistent production processes and continuous improvement. Product-specific certifications vary by region and application; for architectural glass, these often include CE marking for European markets (EN standards like EN 1096 for coated glass), SGCC (Safety Glazing Certification Council) for safety glazing in North America (ANSI Z97.1 and CPSC 16 CFR 1201), and ASTM International standards (e.g., ASTM E2188/E2189/E2190 for Insulating Glass Units, ASTM C1376 for coated architectural glass). For specific applications like fire-rated or ballistic glass, additional specialized certifications are required. Our company rigorously adheres to these global standards, investing significantly in regular audits and re-certifications to maintain our standing as a trusted supplier of high-quality coated glass. Our testing laboratories are equipped with the latest technology, and our technical team comprises certified experts dedicated to ensuring every sheet of glass meets or exceeds the most demanding performance specifications. This robust quality assurance framework not only minimizes the risk of product failure but also ensures that our coated glass products contribute effectively to energy efficiency, occupant comfort, and structural integrity for decades. This dedication to excellence is particularly evident in our Dichroic Glass products, where maintaining consistent color shift and optical properties across large production runs requires exceptional precision and control, validated through extensive testing against industry benchmarks and proprietary internal standards. Our commitment to transparent quality reporting and adherence to international regulatory frameworks reinforces our position as a leader in the global coated glass market, providing clients with superior performance, reliability, and unparalleled trust in every product delivered.

Comprehensive Customer Support, Warranty Commitments, and Illustrative Case Studies for Coated Glass Solutions

Beyond delivering technically superior products, a distinguishing characteristic of a premier coated glass factory is its comprehensive customer support, robust warranty programs, and transparent service delivery. Our commitment to client satisfaction extends throughout the entire project lifecycle, from the initial consultation to post-installation support. Our dedicated technical support team, comprising experienced engineers and product specialists, is readily available to assist clients with product selection, technical specifications, CAD drawings, and performance simulations, ensuring that the chosen coated glass solution perfectly aligns with the project’s specific requirements and architectural vision. We provide detailed guidance on installation procedures, handling instructions, and best practices for ongoing maintenance, all designed to maximize the lifespan and performance of our glass products. Our delivery logistics are meticulously planned to ensure timely and secure shipment, irrespective of the project's scale or geographical location. We understand that project timelines are critical, and our supply chain management is optimized to provide reliable lead times and on-time delivery, minimizing potential delays. Typical delivery cycles for standard orders range from 3 to 6 weeks, while highly customized or large-volume orders may require slightly longer, estimated at 8-12 weeks, with exact schedules provided upon order confirmation and material availability. This transparency and reliability in logistics are crucial for seamless project execution. Our comprehensive warranty covers product performance and material integrity, typically spanning 10 to 20 years, depending on the specific product type and application, offering significant peace of mind to our clients and demonstrating our confidence in the durability and quality of our coatings. This warranty covers manufacturing defects that impair the optical clarity, thermal performance, or structural integrity of the coated glass under normal use conditions, ensuring long-term value and protection for the client's investment.

Our portfolio includes numerous successful application cases that underscore the transformative impact of our coated glass solutions and our collaborative approach. For instance, in a recent high-rise commercial building project in a challenging climate zone, our advanced Low-E coated glass was instrumental in achieving LEED Platinum certification. By specifying a custom coating with an exceptionally low SHGC of 0.20 and a U-value of 1.5 W/m²K, the building significantly reduced its annual energy consumption for cooling by an estimated 35%, leading to substantial operational cost savings and enhanced occupant comfort. Another notable case involved a prominent cultural center seeking a unique aesthetic element; our Dichroic Glass was specified for a large-scale façade installation, transforming the building into a dynamic, color-shifting landmark that interacts with ambient light, drawing considerable public attention and critical acclaim. This project exemplified our ability to blend artistic vision with technical precision, delivering a product that was both visually stunning and highly durable. For a large automotive manufacturer, we provided bespoke anti-reflective and hydrophobic coatings for their premium vehicle lineup, enhancing driver visibility and safety in adverse weather conditions, demonstrating our capability to deliver high-volume, performance-critical solutions. Our client feedback consistently highlights our responsiveness, technical expertise, and dedication to delivering solutions that not only meet but exceed expectations. We maintain a proactive customer relationship management system, ensuring that any inquiries, service requests, or technical assistance needs are addressed promptly and efficiently. This holistic approach to customer service, coupled with our commitment to manufacturing excellence, solidifies our reputation as a trusted partner for all coated glass requirements, providing lasting value and fostering long-term relationships built on reliability and performance.

Frequently Asked Questions (FAQ) about Coated Glass

This section addresses common queries regarding coated glass, providing clarity on its selection, installation, maintenance, and long-term performance. One frequent question is: "What is the lifespan of coated glass?" High-quality coated glass, manufactured by a reputable coated glass factory and installed correctly, typically has a lifespan comparable to that of standard insulating glass units, often exceeding 20-30 years. The durability of the coating is enhanced by its application within an IGU, where the coating is protected within the sealed air or argon space, shielding it from external elements. Another common query revolves around cleaning: "How should I clean coated glass?" While the coating itself is usually durable, it's generally recommended to use mild, non-abrasive cleaning solutions and soft cloths to avoid scratching the surface. Harsh chemicals or abrasive tools should be avoided, especially on exposed coatings. For internal coatings within an IGU, standard glass cleaning procedures apply to the exterior surfaces. "Can coated glass be cut or altered after coating?" Generally, no. Most coatings, especially soft-coat (sputtered) Low-E coatings, are applied after the glass has been cut to size, tempered, or heat-strengthened. Attempting to cut or alter the glass after coating can damage the coating layer and compromise its performance. Therefore, precise measurements and specifications are critical prior to manufacturing. "Does coated glass fade or change color over time?" While some early generation coatings might have shown minimal changes, modern coated glass, particularly from certified manufacturers, is highly stable and designed for long-term optical and thermal performance. The multi-layer metallic or metallic oxide coatings are highly durable and resistant to environmental degradation, ensuring their color and performance remain consistent for decades. Dichroic Glass, by its nature, exhibits dynamic color shifts based on light and viewing angle, which is an inherent feature, not a degradation.

Further frequently asked questions delve into the energy benefits and specific applications of coated glass. "Is the energy saving benefit of coated glass significant?" Absolutely. Studies by organizations like the U.S. Department of Energy indicate that windows account for a substantial portion of building energy loss. Installing high-performance coated glass, especially Low-E glass, can reduce energy consumption for heating and cooling by 20-40% or more, leading to substantial cost savings and a significant reduction in greenhouse gas emissions over the building's lifetime. "What are the common applications for Dichroic Glass beyond architecture?" While widely used in architectural design for facades, skylights, and interior partitions, Dichroic Glass also finds applications in artistic installations, retail displays, stage lighting filters, and even in specialized optical instruments where precise spectral manipulation is required. Its unique optical properties make it a favored choice for creating striking visual effects and dynamic light environments. "How does a coated glass factory ensure the quality and consistency of its products?" Through rigorous multi-stage quality control, adherence to international standards (e.g., ISO, ASTM, EN), continuous process monitoring using advanced sensors, and comprehensive in-house and third-party testing. This includes optical performance validation, accelerated weathering tests, and durability assessments to guarantee long-term performance and reliability. Our commitment to excellence is reflected in our robust manufacturing processes, stringent quality checks, and comprehensive product warranties, providing our clients with peace of mind and superior performance.

Further Reading and Resources:

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS