Aug . 09, 2025 04:00 Back to list

Premium Frosted Glass: Privacy, Style & Custom Options

In the dynamic world of architecture, interior design, and specialized industrial applications, the demand for materials that offer both aesthetic appeal and practical functionality is ever-increasing. Among these, frosted glass stands out as a quintessential solution, expertly balancing privacy with natural light diffusion. This article delves deep into the multifaceted aspects of frosted glass, exploring its industry trends, intricate technical parameters, diverse application scenarios, and unparalleled technical advantages. We will also navigate the complexities of manufacturer comparisons, illustrate bespoke customization solutions, and showcase real-world application cases, all while emphasizing data-driven insights to foster user trust and confidence in this remarkable material.

Current Industry Trends and Market Dynamics of Frosted Glass

The global frosted glass market is experiencing robust growth, driven by escalating demand in the construction, automotive, and consumer electronics sectors. According to a recent market analysis by Grand View Research, the global smart glass market, which includes various forms of privacy glass like frosted options, was valued at USD 5.0 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 15.6% from 2023 to 2030. This growth is largely attributable to increasing urbanization, a heightened focus on energy efficiency in buildings, and the growing preference for minimalist and modern design aesthetics.

Emerging trends indicate a strong shift towards sustainable and environmentally friendly manufacturing processes for frosted glass. Innovations in low-iron content glass for enhanced clarity and improved light transmission, alongside advancements in acid-etching techniques that minimize chemical waste, are becoming industry standards. Furthermore, the integration of smart technologies, such as switchable frosted glass that can transition between transparent and opaque states, is revolutionizing privacy solutions in both residential and commercial spaces. The market also sees a rising demand for specialized applications, including cut frosted glass for intricate design elements and specific thickness requirements like 5mm frosted glass for furniture and shower enclosures.

Technical Parameters and Specifications of Frosted Glass

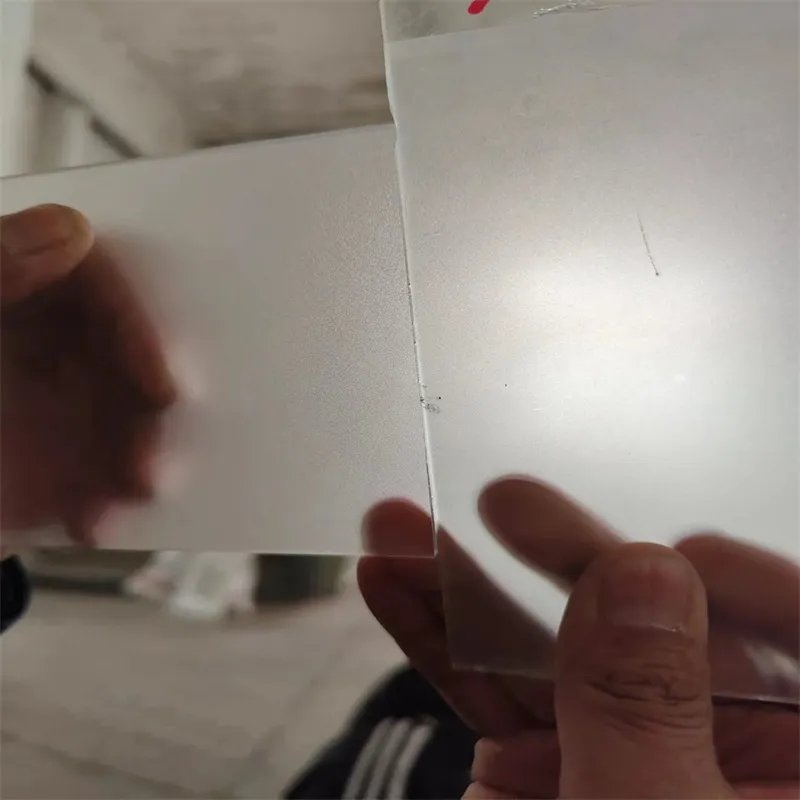

Understanding the technical specifications of frosted glass is crucial for selecting the right product for any given application. The properties of frosted glass are primarily determined by the base glass type, the frosting method (acid etching or sandblasting), and the thickness. Key parameters include light transmission, haze level, thickness tolerance, and resistance to environmental factors.

Frosted Glass Key Technical Specifications Table

| Parameter | Description | Typical Range (for 5mm Frosted Glass) | Relevant Standard |

|---|---|---|---|

| Material Composition | Soda-lime float glass (standard), Low-iron glass (high clarity) | SiO2 (70-74%), Na2O (12-16%), CaO (8-10%) | ASTM C1036, EN 572-2 |

| Thickness | Standard thickness, crucial for structural integrity and acoustic performance. | 2mm to 19mm (5mm frosted glass is common for general use) | ASTM C1036, EN 572-2 |

| Light Transmittance | Percentage of visible light passing through the glass. | 70% - 85% (depending on frosting level) | ISO 9050, ASTM E903 |

| Haze Level | A measure of the diffused light, indicating opacity and privacy level. | 80% - 98% | ASTM D1003 (Haze and Luminous Transmittance) |

| Surface Roughness (Ra) | Micro-roughness of the frosted surface. | 2.0 μm - 8.0 μm (Acid-etched typically smoother than sandblasted) | ISO 4287 |

| Density | Mass per unit volume. | 2.5 g/cm³ | ASTM C729 |

| Thermal Expansion Coefficient | Indicates how much the glass expands or contracts with temperature changes. | 9.0 x 10^-6 /°C (20-300°C) | ISO 7991 |

| Abrasion Resistance | Resistance to surface wear. | Good (Acid-etched generally more resistant than sandblasted) | ASTM D4060 (Taber Abrasion Test) |

| Chemical Resistance | Ability to withstand chemical attack. | Excellent against most acids, alkalis, and solvents | ISO 695, ISO 719, ISO 720 |

These parameters are critical in determining the suitability of frosted glass for specific environments, from high-humidity bathrooms to high-traffic commercial spaces. For instance, 5mm frosted glass provides a good balance of durability and aesthetic appeal for interior doors, partitions, and tabletops.

Frosted Glass Manufacturing Process Explained

The creation of frosted glass involves a precise and controlled transformation of clear glass into a translucent masterpiece. The two primary manufacturing processes are acid etching and sandblasting, each yielding distinct surface characteristics and performance attributes.

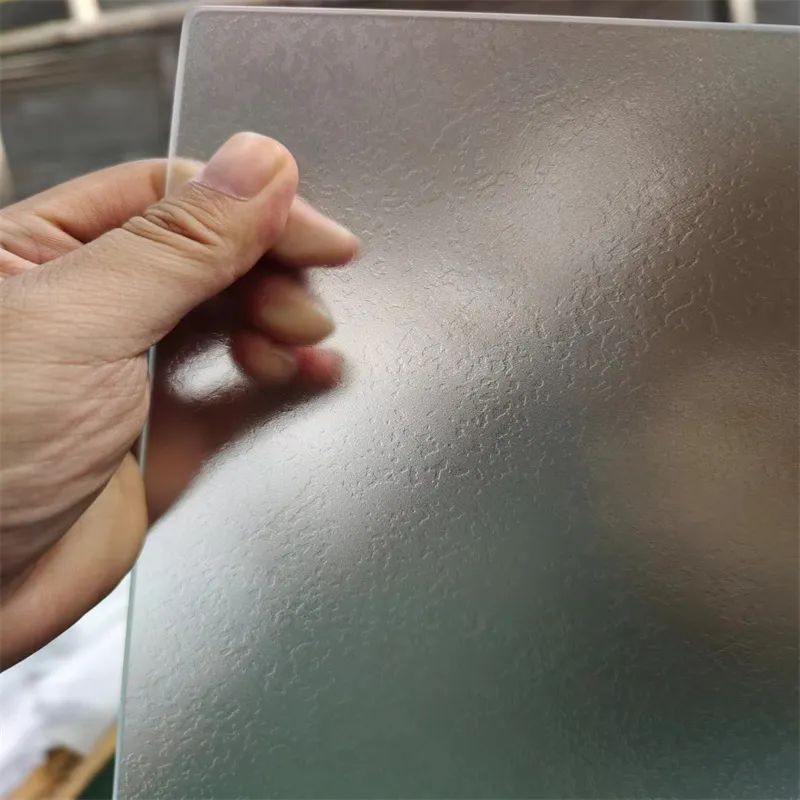

1. Acid Etching Process

Acid etching is a chemical process that involves treating one or both sides of a clear float glass sheet with a corrosive acid solution, typically hydrofluoric acid. This acid reacts with the silica in the glass, subtly dissolving the surface to create a uniformly smooth, frosted finish. The process highlights the material's inherent quality and results in a durable, easy-to-clean surface.

- Step 1: Glass Preparation - High-quality clear float glass is thoroughly cleaned to remove any impurities, ensuring a flawless etching surface.

- Step 2: Acid Application - The glass sheets are conveyed through a controlled environment where they are immersed in or sprayed with a precisely formulated hydrofluoric acid solution. The concentration of the acid and the duration of exposure dictate the degree of frosting and surface texture.

- Step 3: Reaction & Neutralization - The acid reacts with the glass, creating the desired frosted effect. After the etching process is complete, the glass is rinsed thoroughly with water to remove residual acid, followed by a neutralization bath to ensure all chemical reactions cease and the surface is stable.

- Step 4: Washing & Drying - The glass is then meticulously washed to remove any residues and dried, preparing it for inspection and subsequent processing (e.g., cutting, tempering).

Material Highlight: The base material is typically high-quality soda-lime float glass, known for its clarity and flatness, ensuring a consistent frosted finish. For enhanced clarity and light transmission, low-iron glass is often used as the base for acid-etched frosted glass.

Advantages: Acid-etched frosted glass offers a very smooth, uniform, and permanent finish that is resistant to fingerprints and stains, making it ideal for high-traffic areas and applications requiring easy maintenance. Its subtle sheen and consistent light diffusion are highly valued.

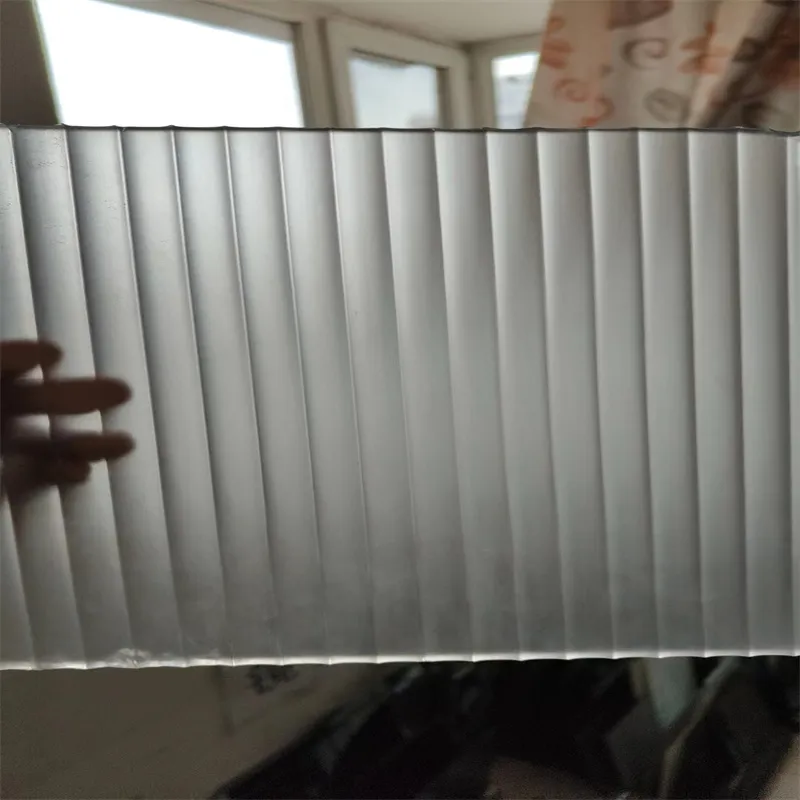

2. Sandblasting Process

Sandblasting, or abrasive blasting, is a mechanical process where high-pressure streams of abrasive particles (such as sand, aluminum oxide, or silicon carbide) are directed at the glass surface. This impact creates microscopic pits and roughens the surface, resulting in a diffused, opaque appearance.

- Step 1: Glass Preparation - Similar to acid etching, the clear glass sheets are cleaned.

- Step 2: Masking (Optional) - For patterns or designs, specific areas of the glass are masked off with a protective stencil material, allowing only the exposed areas to be frosted. This is particularly relevant for creating intricate cut frosted glass designs.

- Step 3: Abrasive Blasting - The glass is placed in a sandblasting booth, where abrasive media is propelled at high speed using compressed air. The pressure, type of abrasive, and duration of blasting determine the depth and texture of the frosting.

- Step 4: Cleaning - After blasting, the glass is cleaned to remove any residual abrasive particles and dust.

Manufacturing Process Insight: While sandblasting offers greater flexibility for custom patterns and textures, it can sometimes result in a rougher surface compared to acid etching, which may be more prone to collecting dirt or fingerprints. However, advancements in sealing technologies can mitigate this.

Inspection Standards: Throughout both processes, stringent quality control measures are implemented. Products are routinely checked against international standards such as ISO 9001 (Quality Management Systems) and ANSI Z97.1 (Safety Glazing Materials Used in Buildings) for clarity, uniformity, thickness, and safety. Each batch undergoes visual inspection for defects and instrumental analysis for light transmittance and haze level.

Usage Lifespan: When properly manufactured and installed, frosted glass has an exceptionally long lifespan, often exceeding 30-50 years, comparable to that of standard clear glass. Its durability is enhanced by its resistance to UV degradation, moisture, and temperature fluctuations. The frosted surface itself is highly durable and permanent, unlike films or coatings that can peel or degrade over time.

Technical Advantages and Applicable Industries

The unique properties of frosted glass render it exceptionally advantageous across a spectrum of industries, providing solutions that combine aesthetics, functionality, and performance.

Key Technical Advantages:

- Enhanced Privacy: The primary advantage. Frosted glass scatters light, obscuring direct visibility while still allowing light to pass through. This is crucial for bathrooms, meeting rooms, and office partitions.

- Optimal Light Diffusion: Unlike opaque materials, frosted glass softens harsh direct sunlight, reducing glare and creating a more evenly lit, comfortable interior environment. This contributes to energy efficiency by reducing the need for artificial lighting during daylight hours.

- Aesthetic Versatility: It offers a modern, sophisticated aesthetic that can complement various design styles. Its neutral appearance allows it to blend seamlessly into contemporary, minimalist, or even traditional settings. The ability to create cut frosted glass with intricate patterns further enhances its design flexibility.

- Durability and Low Maintenance: The frosting process is permanent, integrated into the glass itself, making it highly durable and resistant to fading, scratching, and peeling unlike applied films. Acid-etched frosted glass is particularly resistant to smudges and fingerprints, making cleaning easy.

- Increased Safety: In certain applications, particularly for partitions or doors where transparency could lead to accidental collisions, frosted glass enhances safety by making the glass more visible, particularly if it's tempered or laminated for added strength.

Applicable Industries and Typical Scenarios:

- Architecture & Construction (Residential & Commercial):

- Privacy Screens: Bathrooms, shower enclosures, internal doors (e.g., 5mm frosted glass for shower screens due to its safety and light diffusion properties).

- Office Partitions: Creating private workspaces while maintaining an open feel and allowing light penetration, fostering a collaborative yet focused environment.

- Facades & Windows: For areas requiring privacy from external views or to mitigate harsh direct sunlight, improving indoor comfort and reducing HVAC load.

- Railings & Balustrades: Offering a contemporary look while ensuring safety and privacy on balconies or staircases.

- Interior Design & Furniture:

- Tabletops & Shelving: Adding elegance and reducing glare, particularly for cut frosted glass custom designs.

- Cabinet Doors: Obscuring contents while adding a touch of sophistication.

- Decorative Panels: Used as design features in walls, ceilings, or backsplashes.

- Automotive:

- Privacy Glass: For vehicle rear windows or partition windows in luxury vehicles and limousines.

- Interior Accents: In dashboards or interior lighting components for diffused light.

- Retail & Hospitality:

- Shop Fronts & Displays: Creating intriguing visual effects and controlling visibility.

- Restaurant & Hotel Partitions: Defining spaces and enhancing ambiance with diffused light.

- Medical & Healthcare:

- Clinic Partitions & Doors: Providing patient privacy in waiting areas, examination rooms, or laboratories.

- Industrial Applications (e.g., Petrochemical, Metallurgy, Water Supply/Drainage):

- While less direct, frosted glass (especially tempered and laminated versions) can be used in control rooms or observation windows where diffused light and privacy are required without compromising safety or structural integrity. Its inherent chemical resistance makes it suitable for environments with certain corrosive agents. For instance, in control panels in water treatment plants (given proper sealing and mounting), frosted glass could diffuse indicator lights or provide a semi-private viewing area.

In essence, the technical advantages of frosted glass like energy efficiency (through light diffusion), durability, and privacy make it an indispensable material for a wide array of sectors, constantly finding new and innovative applications.

Choosing Your Supplier: Manufacturer Comparison and Customization Solutions

When looking to buy frosted glass, selecting the right manufacturer is paramount to ensuring quality, reliability, and value. The market offers a diverse range of suppliers, from large international corporations to specialized boutique manufacturers. A careful comparison based on specific criteria can help you make an informed decision.

Key Factors for Manufacturer Comparison:

- Quality Certifications: Look for manufacturers adhering to international quality standards such as ISO 9001 (Quality Management System), ASTM (American Society for Testing and Materials), and EN (European Norms). These certifications signify a commitment to consistent product quality and reliable manufacturing processes. Our products adhere strictly to these benchmarks, ensuring superior performance and longevity.

- Manufacturing Capabilities: Evaluate their capacity for various processes (acid etching vs. sandblasting), ability to handle different thicknesses (e.g., 5mm frosted glass up to 19mm), and special treatments (tempering, laminating).

- Customization Expertise: A leading manufacturer should offer comprehensive customization options, including precise cut frosted glass services, bespoke patterns, and various levels of opacity.

- Experience and Reputation: Companies with a long history (e.g., over 15 years in the industry) and positive client testimonials often indicate reliability and deep industry knowledge. Our extensive track record serving global clients across diverse industries speaks volumes about our commitment and expertise.

- Sustainability Practices: Inquire about their environmental policies, waste management, and energy consumption during production.

- Customer Support & After-Sales Service: Responsive communication, technical support, and clear warranty policies are crucial indicators of a trustworthy partner.

- Logistics and Delivery: Assess their ability to manage complex shipping requirements, especially for international orders, ensuring timely and secure delivery.

Tailored Customization Solutions:

One of the most significant advantages of partnering with a specialized frosted glass manufacturer is the ability to obtain highly customized solutions. Whether you need specific dimensions, unique patterns, or particular performance characteristics, customization ensures the glass meets your exact project requirements.

- Precision Cutting and Edging: Utilizing advanced CNC machinery, manufacturers can provide highly accurate cut frosted glass to virtually any shape or size, from intricate designs for decorative panels to large architectural elements. Various edge finishes (flat polished, beveled, pencil polished) are also available.

- Custom Frosting Patterns and Levels: Beyond standard full-surface frosting, manufacturers can create bespoke patterns, logos, or gradients using masking techniques during sandblasting or specific acid formulations for etching. The level of opacity can also be fine-tuned to achieve the desired balance of privacy and light transmission.

- Thickness and Substrate Options: While 5mm frosted glass is common, customization extends to a full range of thicknesses. Clients can also specify low-iron glass for maximum clarity, or opt for tinted base glass before frosting to achieve unique color effects.

- Safety Enhancements: For applications requiring increased strength and safety, frosted glass can be custom-tempered (toughened) to be four to five times stronger than annealed glass, or laminated with a PVB or SGP interlayer for enhanced security and acoustic insulation. These treatments do not compromise the frosted finish.

- Integrated Solutions: Leading manufacturers can also integrate frosted glass into insulated glass units (IGUs) for thermal performance, or combine it with smart glass technology for switchable privacy.

By leveraging these customization capabilities, architects, designers, and industrial clients can unlock the full potential of frosted glass, creating unique, functional, and aesthetically striking environments that precisely match their vision.

Real-World Application Cases and Client Feedback

Our commitment to delivering high-quality frosted glass solutions is best exemplified through our successful projects and positive client testimonials. These cases highlight the practical advantages and versatile applications of our products, reinforcing our expertise and reliability in the industry.

Case Study 1: Commercial Office Refurbishment – Enhancing Collaborative Spaces

Challenge: A fast-growing tech company needed to reconfigure its open-plan office into more defined, yet still naturally lit, collaborative zones and private meeting rooms without sacrificing the contemporary aesthetic.

Solution: We supplied over 1,500 square meters of 5mm frosted glass panels, primarily for internal partitions and door inserts. The acid-etched finish provided the perfect balance of privacy for confidential discussions while allowing ambient light to penetrate deep into the office space, reducing the reliance on artificial lighting.

Outcome: The client reported a significant improvement in employee comfort and productivity. The frosted glass partitions created a more focused work environment, and the aesthetic uplift was highly praised. "The frosted glass from China Mirror Glass transformed our office. It's modern, provides excellent privacy, and maintains a bright, open feel. Installation was seamless, and the quality is outstanding," stated the Facilities Manager.

Case Study 2: Boutique Hotel Design – Luxurious Bathroom Enclosures

Challenge: A luxury boutique hotel chain aimed to create stylish, spa-like bathrooms in its new property, requiring sophisticated privacy solutions for shower and toilet enclosures that would still allow light to flow through the space.

Solution: We provided custom cut frosted glass for all shower screens and toilet cubicle doors. The design incorporated a specific sandblasted pattern on the lower half of the panels, transitioning to a lighter frost towards the top, achieving both optimal privacy and a refined aesthetic. The glass was also tempered for enhanced safety, meeting stringent hotel industry standards.

Outcome: The hotel's interior designers lauded the superior finish and precision of the customized frosted glass. Guests consistently provided positive feedback on the elegant and private bathroom environments. "The bespoke frosted glass panels added a unique touch of luxury and privacy to our hotel bathrooms. The quality and craftsmanship were exceptional, making the investment truly worthwhile," commented the Lead Interior Designer.

Case Study 3: Residential Project – Custom Kitchen Cabinetry

Challenge: A homeowner desired to modernize their kitchen with new cabinetry that would offer a soft, diffused view of contents rather than clear transparency, providing a clean, uncluttered look.

Solution: We supplied a batch of acid-etched frosted glass cut to precise measurements for insertion into custom-built cabinet doors. The 4mm thick frosted glass was ideal for this application, offering durability without excessive weight, and its smooth surface was easy to maintain.

Outcome: The homeowner was delighted with the transformation. The frosted glass cabinets added a contemporary elegance to the kitchen, effectively concealing kitchenware while contributing to a brighter space. "I wanted something unique for my kitchen cabinets, and the frosted glass delivered perfectly. It looks amazing, hides clutter, and was exactly what I envisioned. The process of buying frosted glass from them was straightforward and efficient," the homeowner shared.

Commitment to Quality, Trust, and Support

At China Mirror Glass, our dedication extends beyond manufacturing superior frosted glass. We are committed to building long-term relationships based on trust, transparency, and unparalleled customer support. Our adherence to stringent quality assurance protocols, comprehensive certifications, and robust customer service infrastructure ensures that every client experiences peace of mind from inquiry to installation and beyond.

Quality Assurance and Certifications:

Our manufacturing processes are meticulously controlled and regularly audited to comply with the highest international standards. We are proud to hold:

- ISO 9001:2015 Certification: Demonstrating our commitment to a robust Quality Management System, ensuring consistent product quality and customer satisfaction.

- ANSI Z97.1 and EN 12150 (Tempered Glass): Compliance with these safety glazing standards guarantees that our frosted glass, especially when tempered, meets rigorous impact resistance requirements for building applications, enhancing user safety.

- CE Marking: For products destined for the European market, signifying conformity with health, safety, and environmental protection standards.

All raw materials are sourced from reputable suppliers and undergo strict incoming quality control. Each batch of frosted glass undergoes comprehensive testing for light transmission, haze, thickness uniformity, and surface integrity before dispatch. This unwavering commitment to quality ensures that when you buy frosted glass from us, you receive a product of unmatched excellence and reliability. Our products are designed for exceptional longevity, typically lasting several decades without degradation, minimizing replacement costs and environmental impact.

Delivery and Logistics:

We understand the importance of timely and secure delivery. Our logistics team specializes in handling glass products, ensuring careful packaging and efficient shipping worldwide. We offer flexible delivery options, from LCL (Less than Container Load) for smaller orders to FCL (Full Container Load) for large-scale projects. Our average lead time for standard frosted glass orders is typically 15-20 business days from order confirmation, with customized or large volume orders quoted separately based on complexity. We provide real-time tracking and dedicated support throughout the shipping process.

Warranty and Customer Support:

We stand behind the quality of our frosted glass products. All our frosted glass comes with a comprehensive 5-year limited warranty against manufacturing defects. This covers issues related to the frosted finish, material integrity, and conformity to specified parameters under normal use conditions. Our dedicated customer support team is available to assist with technical queries, order tracking, and any after-sales concerns. We pride ourselves on responsive communication and proactive problem-solving, ensuring a smooth and satisfactory experience for every client.

Frequently Asked Questions (FAQ) about Frosted Glass

To further enhance clarity and address common inquiries, here are answers to frequently asked questions regarding frosted glass.

Q1: What is the primary difference between acid-etched and sandblasted frosted glass?

A1: Acid-etched frosted glass is created by chemically treating the glass surface, resulting in a very smooth, uniform, and translucent finish that is highly resistant to fingerprints. Sandblasted frosted glass is made by mechanically abrading the surface with high-pressure particles, leading to a slightly rougher texture that can offer a higher degree of opacity and is more suitable for creating custom patterns like cut frosted glass designs. Both provide privacy and light diffusion.

Q2: Is frosted glass suitable for outdoor use?

A2: Yes, frosted glass is highly durable and resistant to environmental factors like UV radiation and moisture. It can be used in exterior applications such as facades, balustrades, and privacy screens. For outdoor use, it is often recommended to use tempered or laminated frosted glass for enhanced safety and structural integrity against wind loads and impacts.

Q3: How do I clean frosted glass?

A3: Cleaning frosted glass is straightforward. For acid-etched surfaces, a soft cloth with warm water and mild soap is usually sufficient. Sandblasted surfaces might benefit from a soft brush to dislodge particles from the textured surface before wiping. Avoid abrasive cleaners or harsh chemicals that could damage the finish. Regular cleaning helps maintain its aesthetic appeal and light diffusion properties.

Q4: Can frosted glass be tempered or laminated?

A4: Absolutely. Frosted glass can undergo further processing like tempering (heat-strengthening) to increase its strength by 4-5 times, making it a safety glass that shatters into small, blunt pieces upon breakage. It can also be laminated with a PVB or SGP interlayer for enhanced security, sound insulation, and to hold shattered pieces together. This is especially common for 5mm frosted glass used in shower doors or commercial partitions.

Q5: What are the typical thickness options available for frosted glass?

A5: Frosted glass is available in a wide range of thicknesses, commonly from 2mm to 19mm. Popular thicknesses include 5mm frosted glass for interior doors and shower screens, 6mm and 8mm for partitions, and thicker options for structural glazing or high-impact areas. The choice of thickness depends on the application's structural requirements, safety needs, and desired acoustic performance.

Q6: Does frosted glass reduce light transmission significantly?

A6: While frosted glass diffuses light, it does not significantly reduce overall light transmission compared to opaque materials. Depending on the level of frosting and the base glass, light transmittance typically ranges from 70% to 85%. This allows for ample natural light penetration, creating bright interiors while providing effective visual privacy.

Q7: Can frosted glass be used for smart glass applications?

A7: Yes, it can. Technologies like switchable privacy glass often integrate a polymer dispersed liquid crystal (PDLC) film between two layers of glass, which can then be frosted on one or both sides. This creates a dual-function glass that offers both electronic switchable privacy and the subtle aesthetic of frosted glass when opaque, making it a highly versatile solution for dynamic spaces.

Conclusion: The Enduring Value of Frosted Glass

Frosted glass is more than just a functional material; it is a sophisticated design element that offers an unparalleled blend of privacy, light diffusion, and aesthetic appeal. From its meticulous manufacturing processes—whether through the uniform smoothness of acid etching or the textured versatility of sandblasting—to its widespread applications across diverse industries, frosted glass continues to redefine spaces. Its technical advantages, including energy efficiency through natural light optimization and its inherent durability, underscore its value in modern architecture and design.

Our commitment to excellence is reflected in every sheet of frosted glass we produce, rigorously adhering to international standards such as ISO and ANSI. By offering extensive customization options, including precise cut frosted glass and a range of thicknesses like 5mm frosted glass, we empower architects, designers, and builders to realize their most ambitious visions. Through transparent communication, reliable delivery, and robust after-sales support, we strive to be your trusted partner in sourcing premium frosted glass solutions. Embrace the elegance and functionality of frosted glass to transform your next project into a masterpiece of diffused light and sophisticated privacy.

Further Reading and References:

- Grand View Research. (2023). Smart Glass Market Size, Share & Trends Analysis Report By Technology (SPD, EC, PDLC), By Application (Automotive, Architectural, Power Generation), By Region, And Segment Forecasts, 2023 - 2030. Retrieved from https://www.grandviewresearch.com/industry-analysis/smart-glass-market

- Glass Magazine. (2022). "Advances in Decorative Glass." Retrieved from https://glassmagazine.com/news/advances-decorative-glass (Please note: specific articles within this domain might require subscription or direct search.)

- The Glass Association of North America (GANA) Publications. For technical data and standards on various glass types. (Specific links may vary) - Example: https://www.glass.org/glass-technical-papers

- Journal of Building Engineering. (Various issues on architectural glazing and daylighting.) - Example: https://www.sciencedirect.com/journal/journal-of-building-engineering

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS